High quality in mold label use for plastic food container

Short description

Q: What is "IML" ?

IML( In Mold Labelling or In Mold Lamination) is a new technology is used in combination with plastic injection molds, which means that the printed and cut thin film label is placed in the mold in advance and then internal surface of label and outside surface of injection body are fully fused through high temperature and high pressure. The molding of production and decoration will be reached at one time, without secondary processing. No extra labeling step or printing is required, which can improve production efficiency.

The IML label are not on the surface but becomes integral part of the container, making is harder to remove.

The IML technology for increasing product outputs while maintaining reproducibility and quality at the same levels.

Specification

| Product name | High quality in mold label use for plastic food container |

| Size | Accept custom |

| Material | Eco-Friendly PP. |

| Surface & performance | Glossy |

| Color | Up to 10 colors |

| Printing | Gravure printing |

| Thickness | 18-110 micron |

| Shape | in roll or pieces, size according to the customer's requests |

| Application | PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc |

| Packaging | PE bag + carton + packing belt + plastic pallet |

| Certification | SGS, FDA, ISO |

| Sample service | Acceptable |

| MOQ | 1000SQ.M (Can be negotiated ) |

| warranty | 3year |

| Delivery time | After receive the payment 15 working days |

| Payment | T/T, Western Union, L/C, Ali accruance pay ;30% deposit and balance before shipment |

| shipment | By air/ Express or by Sea, up to clients |

| Our Advantages | 1..Free samples are available anytime when you need |

| 2.Free design 24 hours online help you | |

| 3.we have 13 sets printing machine and can offer you prompt delivery time. | |

| 4. import inks ,brighter color and perfect performance |

Production Process

- 1: Design

- 2: Making plate/cylinder<about need spend 7 days>

- 3: Prepare raw material

- 4: Prining<about 3 days>

- 5: lamination<3-5 working day>

- 6: Cutting<3-5 working days>

- 7: Cutting small sample and ship to customer test cutting size

- 8: QC

- 9: Packaging

- 10: Delivery

Workshop

Payment and shipping

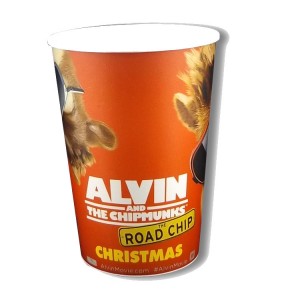

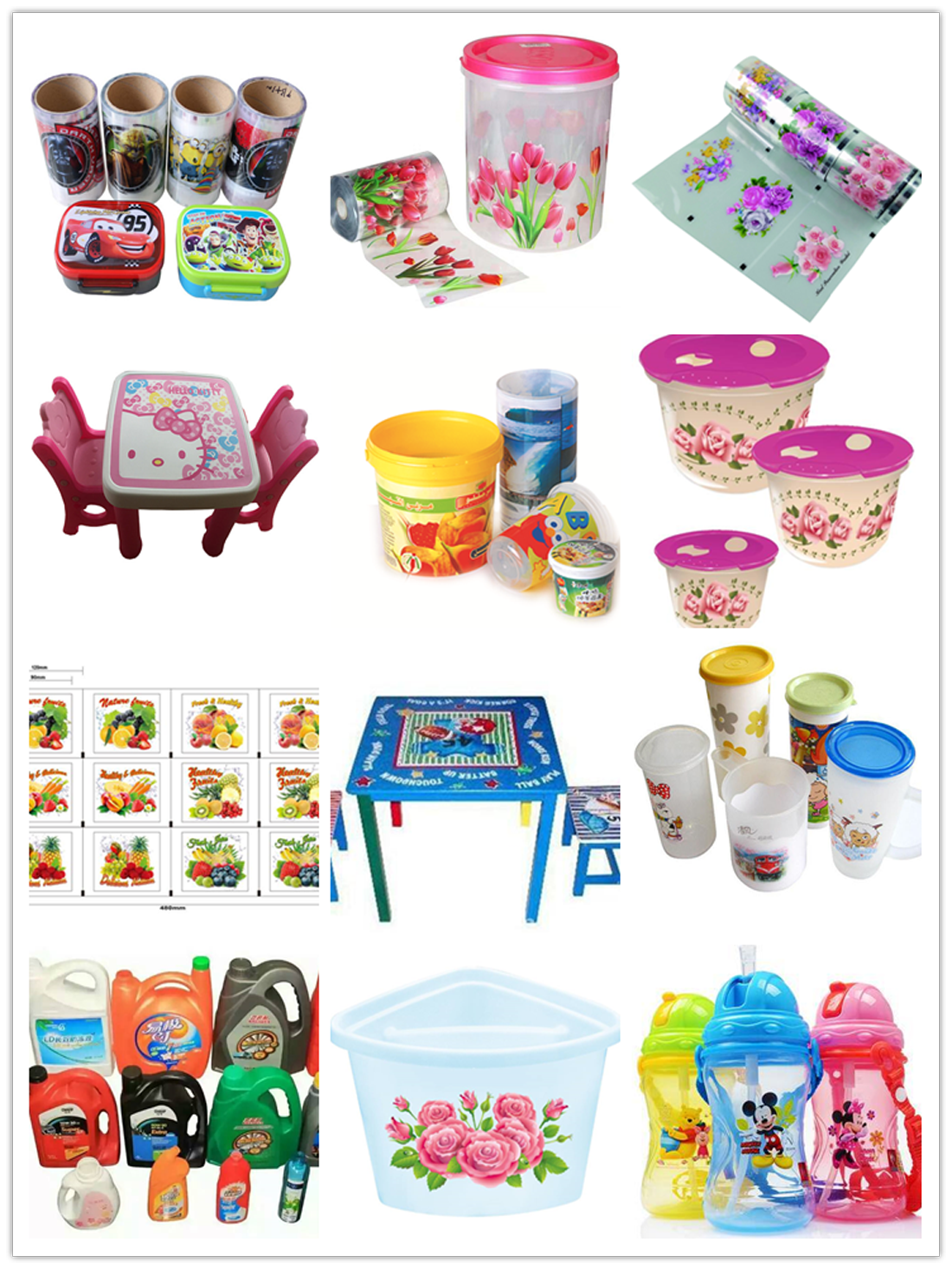

Application Products

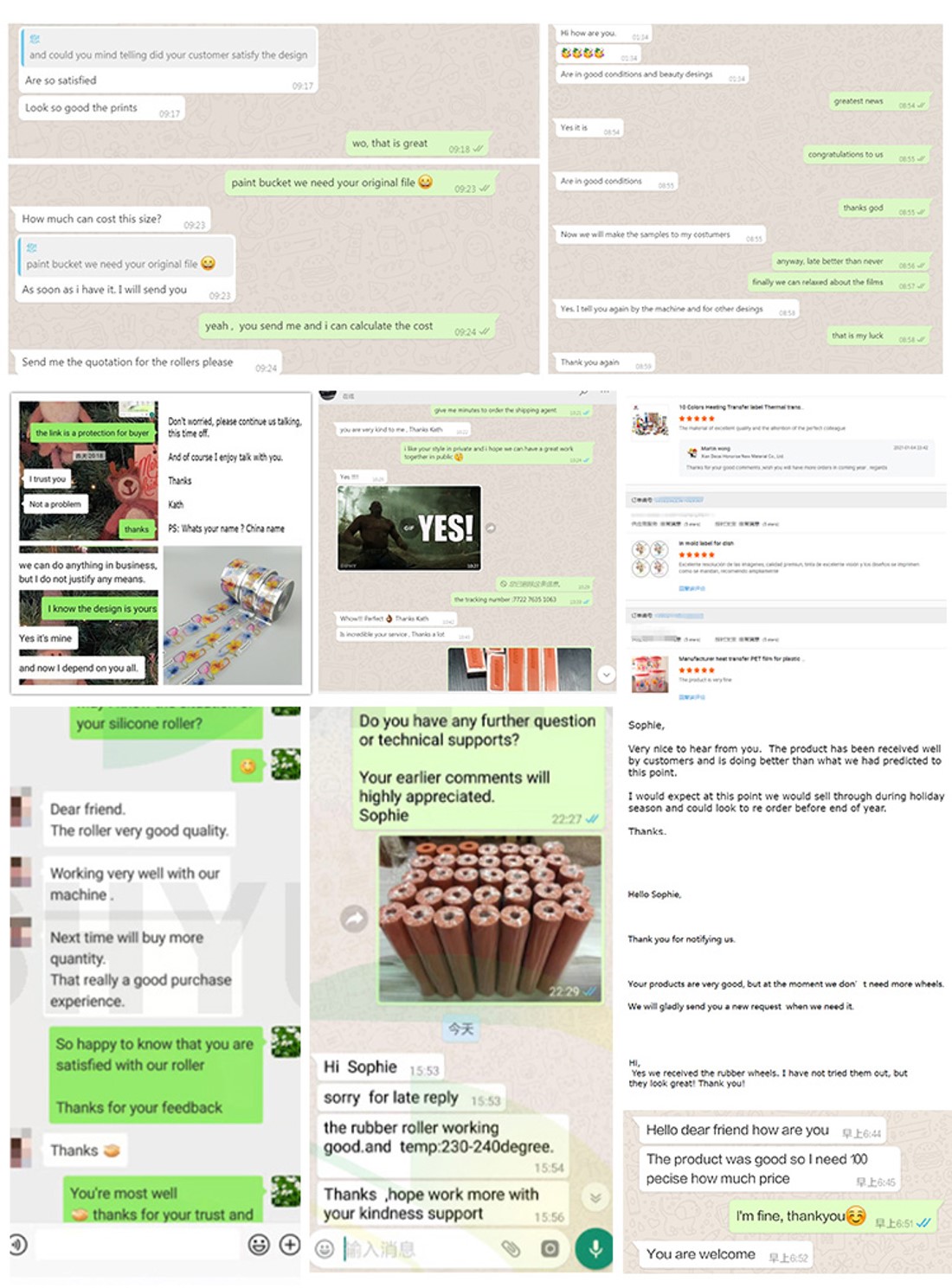

Feedback

Company