2021 cheap and safe in mold laber static charger for IML injection

Specification

|

Technology Parameters

|

||||

|

product name |

In mold label static charger | |||

| usage | Add static during IML injection and printing process | |||

| application | IML for PP.ABS .PE.PET.PVC. ect | |||

| size |

25*15*38cm |

|||

| weight | 7.5kg-8kg | |||

| Power supply | 220v+10% | |||

| Valtage output: 0-30KV | 0-30KV | |||

| Current | 0-1.0MA | |||

| Warranty | 2 year | |||

| Packing | 1 set in cartoon box | |||

| Shiping | by air/express | |||

| Leading time | 2-3 working days after confirm the order | |||

Main Function

Make IML more stable and comfortable.

Details

Short description

Q:What is IML static charger machine (Electrostatic generator)?

The In mold label static charger, utilizes the electrostatic electrostatic field under the action of the electrostatic field.The characteristics of the temporary adsorption material, to achieve temporary temporary fixation of special materials. For printing. Conveying positioning for plastics processing. Adhesive blanking technology floor, glass, high-grade stainless steel, automatic lamination of plastic plates, sticker technology, in-mold film labeling, and other related fields. Pick With this product, the remarkable effect of simple process and improved efficiency can be achieved.

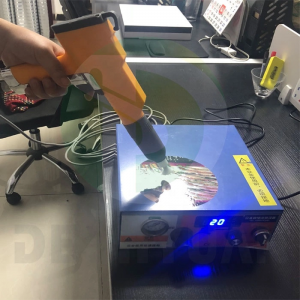

Q: What is the working principle ?

The system is composed of an electrostatic generator and an electrostatic generating electrode. The electrostatic generator provides a high voltage for the electrostatic needle of the electrostatic generating electrode to generate the required charge. The electrostatic generating electrode uses the high voltage generated by the electrostatic generator. The electric charge moves to the surface of the product under the action of the electric field.

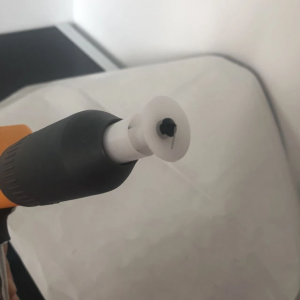

Working principle :Indirect power-up mode:

A metal plate with an antistatic material adhered to the manipulator. The manipulator sucks the label to charge the label through the static generator, and finally places it in the mold.

Working principle: direct power-on mode:

The electrostatic generator is directly installed on the robot hand. When the robot hand places the label on the mold, the electrostatic generator is controlled by PLC to power on the label, and the label will be adsorbed on the mold.

Installation attention

1: Far away from dirty, humid and watery and chemically corrosive environment:

2:must be placed on or under the corresponding plane,

Application Products

Payment and shipping

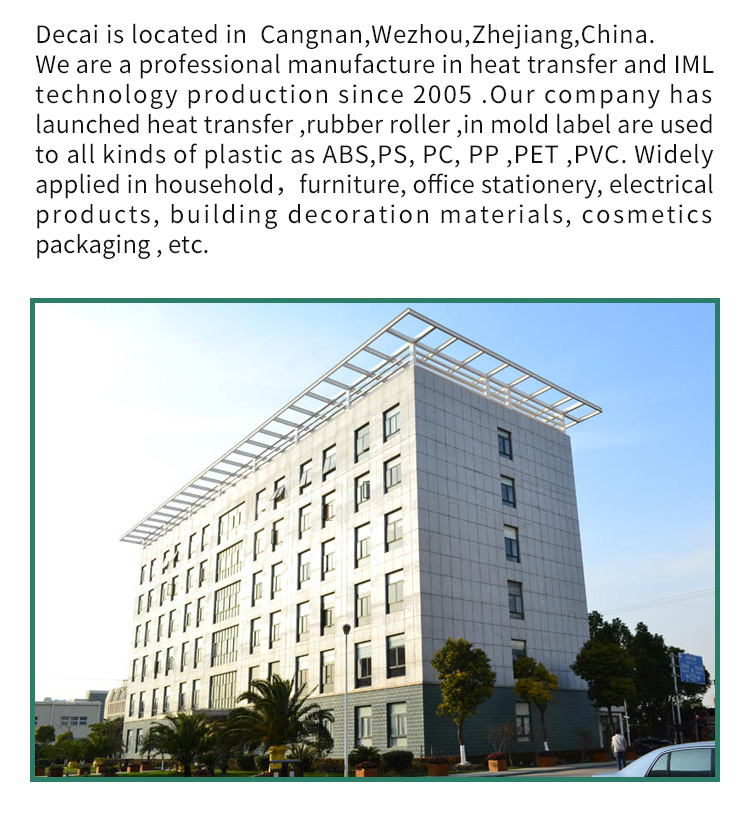

Company information