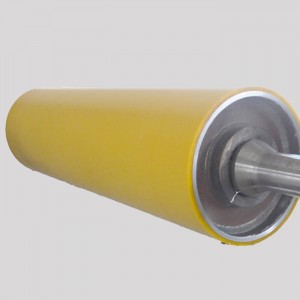

belt conveyor Urethane rubber roller

Rubber roller size:Φ530*Φ500*1600

Shaft material: No. 45 steel + seamless tube

Lagging Material: Polyurethane

Lagging hardness: 80-85 degrees

Concentricity: 0.1mm

Application industry: mining machinery, iron and steel production equipment, large-scale transmission equipment

Polyurethane rubber roller has the advantages of high strength, high tear resistance, and so on. Can withstand high pressure and high humidity production environment. But still pay special attention to its storage. The general method is to seal the colloid with plastic film after cleaning, and place it on the idle polyurethane rubber roller rack. Don't throw it around or press hard to keep the roller core from eccentricity and bending to ensure that the roller core is not eccentric or bent. Use normally.

Therefore, as long as we pay attention to some storage problems, we can prolong the service life of the polyurethane rubber roller. Polyurethane rubber roller

The application of polyurethane rubber rollers began in the early 1980s, and thereafter market demand has increased. The spare parts of polyurethane rubber rollers in the equipment introduced in the papermaking, steel, printing and dyeing, textile and other industries are in urgent need of localization, such as the cold rolling production line, which accounts for 1/3 of the total number of rubber rollers, and the amount is quite objective. In technological transformation and technological innovation, it is urgently needed to replace ordinary rubber rollers to increase production efficiency and save energy consumption. For example, the cost of removing 1kg of water from the drying part of a paper machine is about 10 times higher than that of the pressing part. The roller surface material is made of polyurethane rubber instead of natural rubber, and the linear pressure it bears can be increased by 2 to 3 times, which increases the dehydration rate of the paper.

Q: Are you trading company or manufacturer ?

A: We are a factory integrating R & D, production and sales

Q: How should I get a quote ?

1: Size Specification,such as length,width and thickness

2: Hardness :80-95 Shore A

3: Let me know what machine will you use ?

4: What’s the quantity you need ?

Q:What is your delivery time ?

A: Around 3 days delivery for stock products

Around 15-20 days delivery for customized production.

Q:How do you package the sheet ?

Wooden Case

Q:What is mode of transport ?

A: By express or air or sea.

Q:What’s your payment method ?

A: T/T,Western Union.

Q:Can I get a sample before mass order ?

A: Low cost sample fee + freight charge by yourself;

After you purchase a large quantity, we refund the sample fee

Q:Other Special Support ?

A: Trade Assurance Order By Alibaba