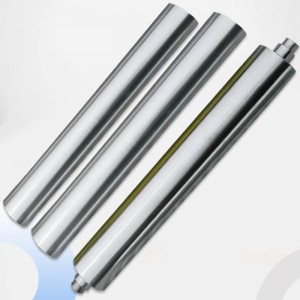

Best Selling Iron Carbon Steel Heavy Duty Aluminum Nylon Caging Window Roller

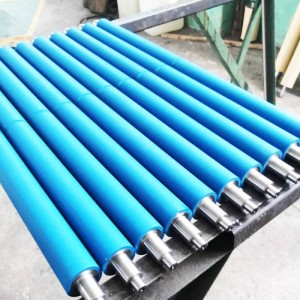

Steel roller are roll-shaped products made of metal or other materials as the core.

According to the purpose, it can be divided into: papermaking rubber rollers, printing and dyeing rubber rollers, printing rubber rollers, grain hulling rubber rollers, metallurgical rubber rollers and mimeograph rubber rollers, etc.;

According to the surface shape, it can be divided into: flat roller and patterned rubber roller;

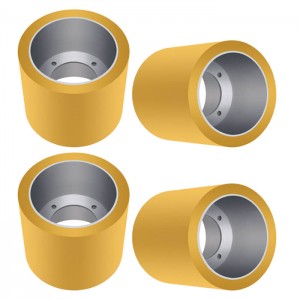

According to the material, it can be divided into: butyl rubber roller, nitrile rubber roller, polyurethane rubber roller and silicone rubber roller. Rubber rollers are generally composed of outer rubber, hard rubber layer, metal core, roller neck and vent holes. Its processing includes roller core sandblasting, bonding treatment, glue forming, cloth wrapping, iron wire winding, vulcanization tank vulcanization and surface processing And other processes. Rubber rollers are mainly used in papermaking, printing and dyeing, printing, food processing, metallurgy, plastic processing, etc.

|

Decai Steel Roller and Rolls Specification

|

|

|

Size

|

Any Size

According To Customer's Drawing

|

|

Material

|

45# steel with plating,stainless steel

|

|

Hardness

|

50-70 degree

|

|

Tolerance

|

0.2mm

|

|

Types

|

Mirror roll, chrome plated, anilox roll |

|

Application Machine

|

industrial machine, printing machine and packaging machines and so on

|

|

Features of rubber roller |

1.Ozone and Chemical resistance

|

|

2.Anti-aging, good flexibility, good elasticity

|

|

|

3.Excellent oil resistance

|

|

|

4.Clean and healthy for many food and medical applications

|

|