Top sales Iml Printing Label in mold labeling for Plastic Paint Bucket

Product Description

Top sales Iml Printing Label in mold labeling for Plastic Paint Bucket

In-mold labeling (IML) or in-mold decorating (IMD) is a process of decorating or labeling injection molded plastic parts or components during the plastic injection molding cycle. The label becomes an integral part of the final product, creating a fully decorated item at press. In this process, a pre-printed label or decorated film is inserted in the open plastic injection mold and held in place via vacuum ports, electrostatic charge, or other method. When the mold is closed, plastic resin is injected into the mold, encapsulating the label permanently within the finished part.

In-mold labeling (IML) was first used in the mid 1970’s as an alternative to decals and pressure sensitive labels. Early adopters quickly realized the benefits of in-mold labeling extend across multiple areas of the business, from enhanced design options and message durability to manufacturing efficiency and improved supply chain management. In-mold technology enabled a significant shift in the labeling and decoration of plastic products. Because parts were now removed from the injection mold fully decorated, manufacturers eliminated additional costly and time consuming post process decoration. Not only did this technology remove the

necessity for a separate process, but it allowed manufacturers to move this entire process to their injection molder. Although IML has become prolific in some industries, certain limitations have prevented some manufacturers from deploying this process. Recent advancements have lifted most of the limitations and created new opportunity for these manufacturers. In-mold technology has advanced significantly since its infancy. Current innovations in three-dimensional (3-D) IML have expanded capabilities and opened in-mold decoration to new product types, allowing the benefits of cost savings and manufacturing efficiencies across nearly all industries. This now provides manufacturers endless options to replace metal forms, painting, dipped coatings, pad printing, and other post production decorative techniques with a durable, high quality, single step label that creates a fully decorated resin part right in the mold.

Our Advantages

Chinese Supplier Cracker/Biscuit/Cookie Food Box Container in Mould Mold Label ImlThe in-mold decorating (IMD) and in-mold labeling (IML) technology enables design flexibility and productivity advantages over traditional post-molding labeling and decorating technologies, including use of multiple colors, effects and textures in a single operation, long-lasting and durable graphics, and overall labeling and decorating cost reductions. With in-mold labeling (IML) and in-mold decorating (IMD), labeling and decorating are complete in the plastic injection molded process, so no secondary operations are required, eliminating post-molding labeling and decorating labor and equipment costs and time. In addition, design and graphic variations are easily achieved by simply changing to different label films or graphic inserts in the same part run. The use of in-mold decorating (IMD) and in-mold labeling (IML) results in high quality and visually impressive graphics and finished parts. The graphics and labeling are also very durable and long lasting, since they are encapsulated in the resin as part of the finished molded plastic part. In fact, the graphics are essentially impossible to remove without destroying the plastic part. With the right films and coatings, in-mold decorated and in-mold labeled graphics will not fade and remain vibrant for the life of the molded plastic part. In-mold decorating (IMD) and in-mold labeling (IML) advantages include: High quality and visually impressive graphics Ability to use flat, curved or 3D-formed labels and graphics Elimination of secondary labeling and decorating operations and costs, since injection molding and labeling/decorating are accomplished in one step Elimination of adhesives with ability to apply labels and graphics on plastic in one step, unlike pressure sensitive labels Ability to apply labels and graphics on plastic parts and containers’ sides and bottoms all in one step, unlike pressure-sensitive labeling Label inventory reduction Ability to achieve high abrasion and chemical resistance using special hard coatings Easy design variations by changing labeling film or graphic inserts, even in the same part run Continuous image transfers with high positioning tolerances Wide range of colors, effects, textures and graphic options

Our company profile

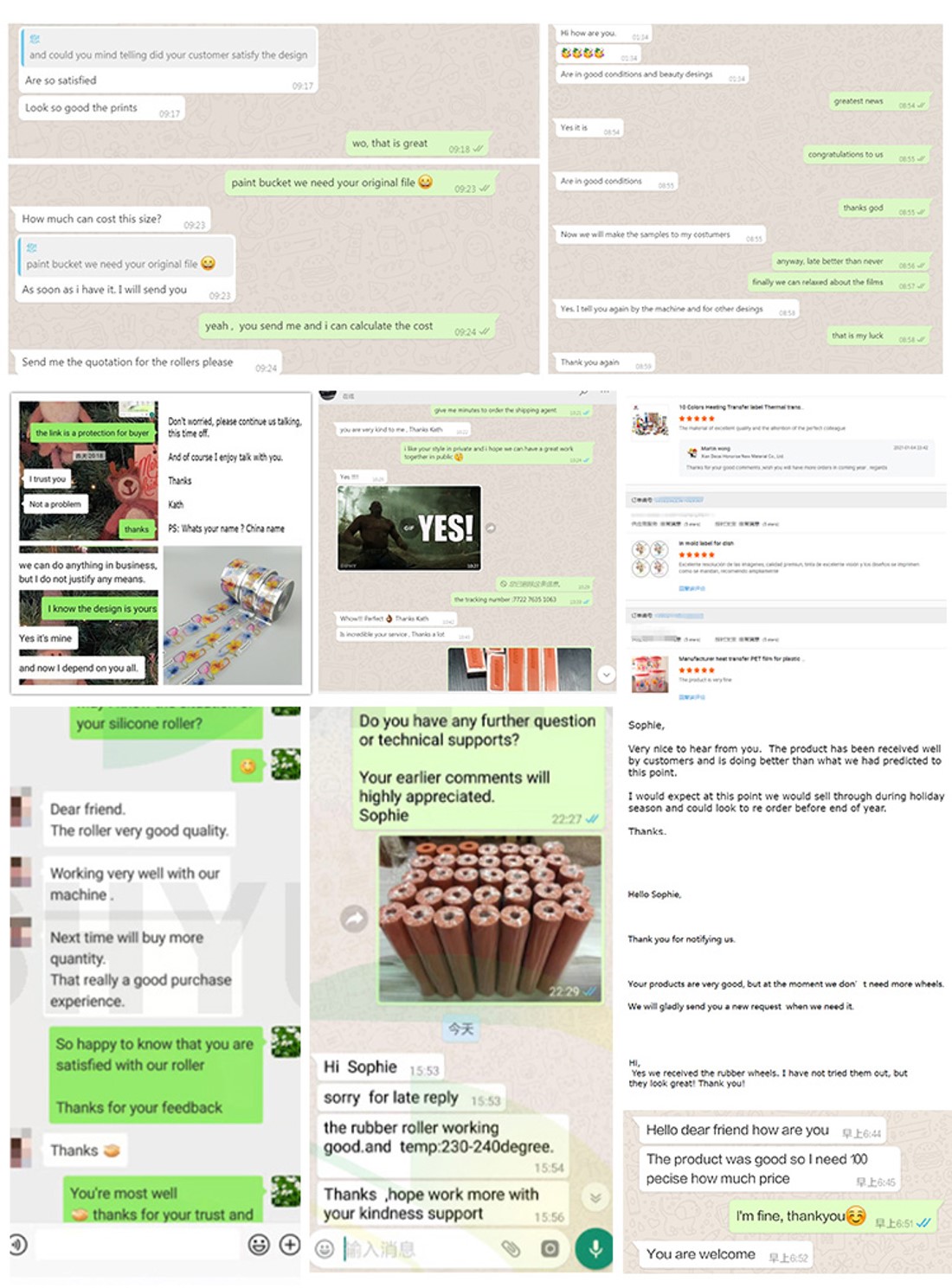

Feedback

FAQ

1.How can we get a quote ?

We will offer you price referring to your detailed request,so please kindly inform us of the material,size,printing color and

other requirements you prefer,and the special offer will be given at once.

2.Can we get some samples?Any Charges?

Yes,you can get available samples in our stock.Free for real samples,but freight cost.

3.How can we know if this product suitable for me?

We can produce various kinds of packing bags&packing films as per your requirements,if you are not sure about the details information,anything about the product you need to know,we can also give some advice for your reference.If you have other questions, you can contact me.

4.Packaging &Shipping

Packaging detail: polybag+carton

Delivery detail: in 7~13 days, by sea/by air/by express,up to customer's requirement.

Contact Us

WhatsApp

0086-17779025926

Wechat:

0086-17779025926

labelprint02_vip@126.com