China Manufacturer In Mold Label for Plastic In mold label sticker for Plate Tray

China Manufacturer In Mold Label for Plastic In mold label sticker for Plate Tray

In mold labeling (IML) is a popular method used for the labeling and decoration of plastic containers and packaging products. This cutting-edge technology involves placing a label or decoration within a mold before the plastic injection process takes place. The label becomes an integral part of the molded plastic and provides an aesthetically pleasing and durable finish. One of the primary reasons for the increasing use of in-mold labeling is its ability to enhance product appearance. With in-mold labeling, the design is protected from scratches, fading, or smudging, ensuring the product maintains its aesthetic appeal over time. IML also offers the ability to produce high-quality graphics that are non-damaged. Another advantage of IML is its ability to streamline the production process. Unlike traditional labeling methods, IML allows manufacturers to reduce labor costs and increase production rates by integrating the labeling process with the molding process. IML also allows for greater design flexibility, making it easier for manufacturers to offer customized solutions to meet the specific needs of the customers. IML also provides environmental benefits by reducing the amount of labeling waste. Traditional labeling techniques require the use of additional materials such as adhesives and substrates, which often end up as waste. However, in-mold labeling eliminates the need for these extra materials, minimizing waste and the ecological footprint of the manufacturing process. In conclusion, the adoption of in-mold labeling has revolutionized the plastic packaging industry, providing several benefits such as enhancing product appearance, increasing production efficiency, and reducing environmental impact. As more companies begin to adopt this method of labeling, it's likely to become the preferred option for branding plastic products.

One of the advantages of heat transfer paper label printing is that it allows you to print your logos and designs onto a matt PET film. This film is ideal for use on plastic surfaces as it is tough, flexible and has excellent adhesion properties. The matt finish gives your labels a professional and stylish look while ensuring that they are easy to read and scan.

Heat transfer paper label printing also allows for the use of a wide range of colors and designs. You can choose from a variety of colors, including metallic, fluorescent and neon colors that can help your labels stand out and attract attention. In addition, you can print intricate designs and patterns that would be difficult to achieve with traditional printing methods.

Furthermore, heat transfer paper label printing is a cost-effective way of producing labels. It eliminates the need for costly printing technologies and materials, making it a popular choice for businesses of all sizes. Moreover, it is environmentally friendly, as it does not produce harmful emissions or waste materials.

In conclusion, heat transfer paper label printing is a reliable and efficient way of producing labels for plastics. With its excellent adhesion properties, wide range of colors and designs, and cost-effectiveness, it is a valuable tool for businesses looking to create high-quality and professional-looking labels.

Our Advantages

In mold labeling offers several major advantages:

Maximum print quality

The offset printing technique ensures high-resolution images. Besides, you can decorate all the sides of a container with one single label.

Strong and hygienic

In mold labels resist humidity and big changes in temperature: the best solution to decorate plastic containers for frozen and refrigerated products! In mold labels are also scratch resistant, cannot crack and are not susceptible to wrinkles.

Shorter production time and lower production costs

During the in mold labeling process containers are produced and decorated in one single step. Storage of blank containers becomes unnecessary, storage and transport costs belong to the past.

Environmentally-friendly

In mold labeling saves the environment: the packaging and the label consist of the same material and can therefore be fully recycled.

Wide range of look & feel options

The same plastic packaging product can be decorated with a wide range of different materials, inks an lacquers. This allows you to differentiate your product on the shelf.

Quick design changeovers

It only takes a shift from one label design to another on your IML automation to make a quick changeover. There is almost no production loss during the start-up of a new design.

Features

1.Environmental protection printing,meet the requierment of international non-toxic standard.

2.Four color process printing design finish in one time,no need for the color register.

3.Simple transfer equipment with vivid printing effect.

4.Strong covering power and good adhesive.

5.High gloss,high image definition,toxic free In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of heat transfer printing film for plastic,pe plastic film, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Production Process

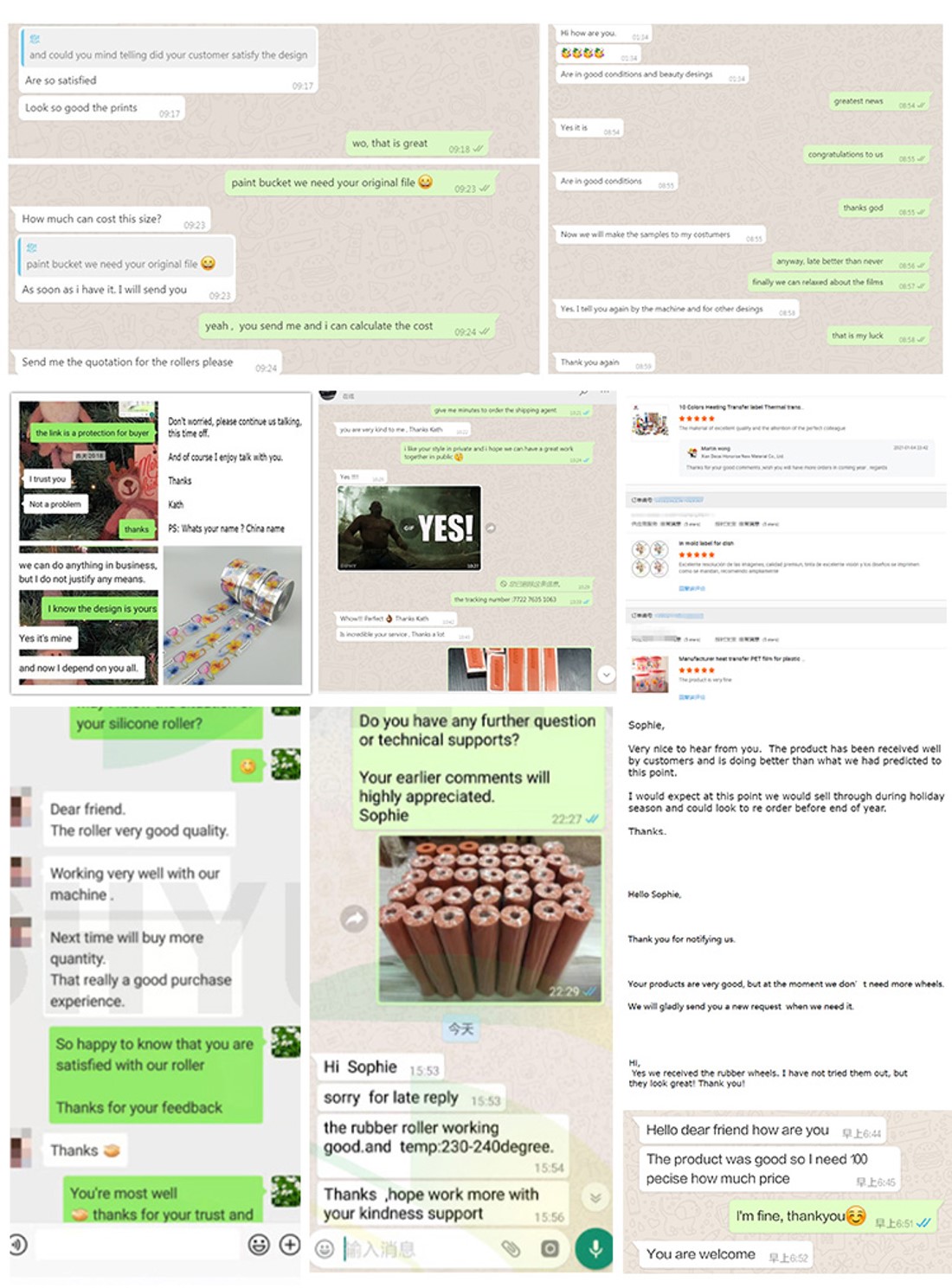

Feedback

Contact Us

WhatsApp

0086-17779025926

Wechat:

0086-17779025926

labelprint02_vip@126.com