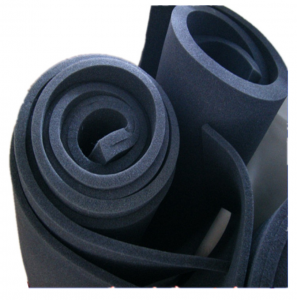

Closed Cell EPDM rubber pads rubber sheet manufacturer

The rubber sheet of EPDM foam material has excellent weather resistance, high and low temperature resistance (its use temperature is -60~125℃), and it has the advantages of resistance to polar oils and chemical reagents. The EPDM foam materials we produce have two types of open cells and closed cells. They are widely used as heat insulation, shock absorption, sound absorption and sealing materials, and are used in automobiles, air conditioning, electronics, audio and other fields.

Our foam products have good heat preservation and heat insulation; low water permeability; cushioning and shock resistance; small bulk density; sound absorption and sound insulation; superior temperature resistance; superior weather resistance; superior oil and solvent resistance, Chemical resistance. In order to meet the requirements of special environments, we can also provide customers with special functions such as flame retardant, conductive, antistatic foam, rubber foam splitting processing, laminating composite processing, and various shoe materials, bag materials, luggage materials , Laminating processing, embossing processing, punching processing, adhesive processing, punch cutting processing;. Widely used in many fields such as automobiles, ships, trains, subways, air conditioners, electronics, audio, construction, bridges, machinery, travel goods and daily necessities

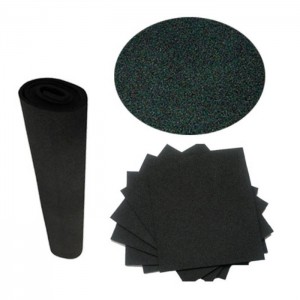

What is EPDM rubber sheet ?

EPDM rubber sheet is also a kind of rubber waterstop. The appearance is very common. It is a bi-planar rubber sheet. The general width is 300mm and the thickness is 8mm. It can also be customized according to customer requirements.

Produce any specification between 200-1500mm, and the thickness can be processed into any thickness between 6-30mm. The oil-resistant rubber waterstop is of neoprene type, which is resistant to oil, acid and alkali.

The physical properties of the rubber sheet can also be processed and customized according to customer needs. The tensile strength T is required to reach 8-20MPA, and the elongation can be made between 150% and 400%.

Application range of EPDM rubber sheet

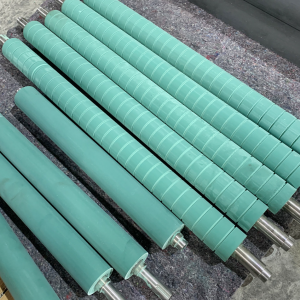

In the industrial industry, rubber sheets are mainly used for anti-corrosion, wear-resistance, and impact resistance to protect the equipment and devices used.

In the mining industry, its rubber sheets are mainly wear-resistant and impact-resistant to describe their equipment and related pipeline equipment, which can extend the service life of its equipment.

The company has a variety of high-precision slitting, compounding, slitting and other finishing equipment and advanced compounding and gluing machines. The polymer foam board can be processed into embossed sheets, rubber bands, and rubber strips according to the different requirements of customers. , Self-adhesive film and various special-shaped pieces.

Application process of EPDM rubber sheet

The scope of use of rubber sheets is relatively wide, and different rubber sheets are selected according to their different working conditions. Different environments and actual use requirements have different selection processes.

For example, the rubber sheet selected for the on-site construction process is a cooked rubber sheet or a self-vulcanized rubber sheet. When the ambient temperature is too high, a vulcanizing tank is used to vulcanize the rubber sheet to improve the performance of the rubber sheet.

Temperature resistance, regarding the construction conditions and working conditions of the rubber sheet, Hengshui Jianfeng Engineering Rubber Co., Ltd. has studied in depth, especially for some more practical technologies, especially for miningAnd the thermal power plant has a short maintenance time and high requirements on the wear resistance of the rubber sheet. The on-site cold bonding technology adopted is more in-depth, which greatly reduces the cost of the enterprise and improves the life.

Related products: EPDM rubber sheet, EPDM rubber