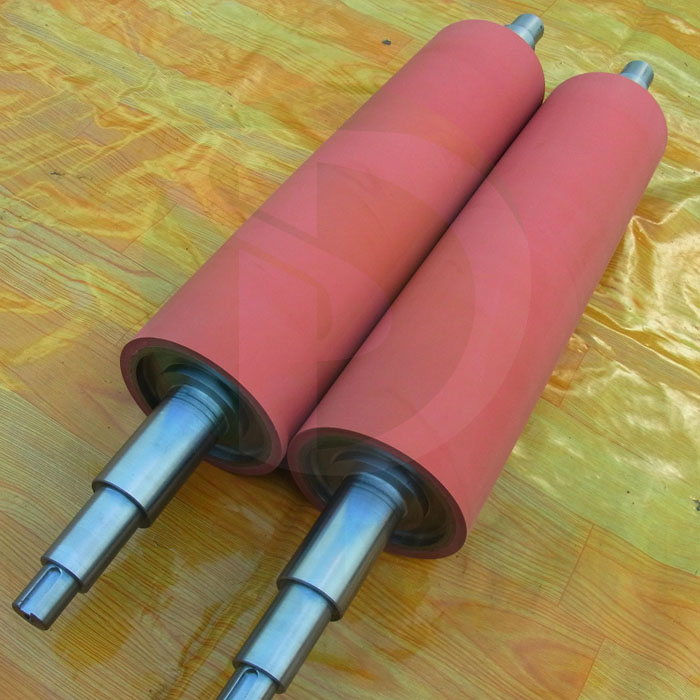

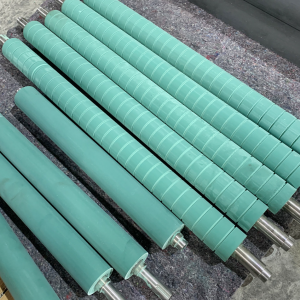

silicon roller for heat transfer printing machine

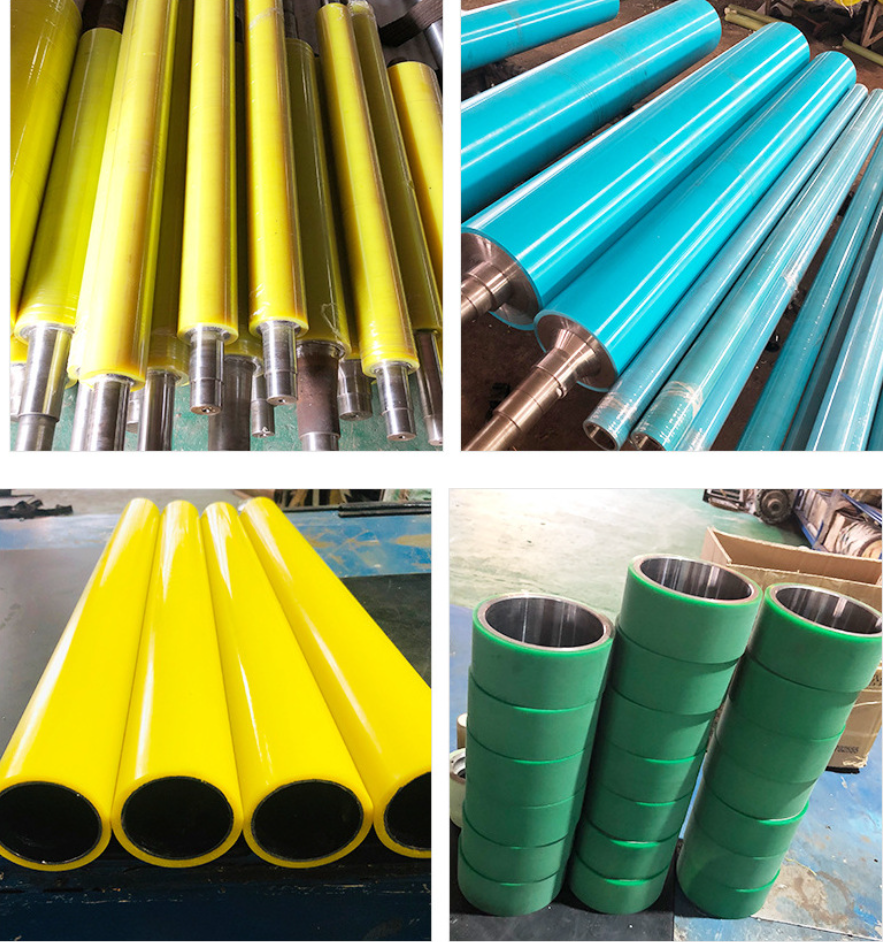

The rubber roller is a roll-shaped product made of metal or other materials as the core and covered with rubber through vulcanization.

According to the purpose, it can be divided into:

|

Decai Rubber Roller Specification

|

|

|

Size

|

Dia:10MM-670MM;

Length:50MM-8200MM

According To Customer's Drawing

|

|

Material

|

NBR,Silicone,Rubber,Polyurethane,NR,PU FFPM,ETC,EPDM

|

|

Hardness

|

18A-100D

|

|

Tolerance

|

0.05mm

|

|

Color

|

yellow,Black, orange,green or custome required

|

|

Core Material

|

stainless steel,45#steel or aluminum

|

|

Application Machine

|

industrial machine, printing machine and packaging machines and so on

|

|

Features of rubber roller |

1.Ozone and Chemical resistance

|

|

2.Anti-aging, good flexibility, good elasticity

|

|

|

3.Excellent oil resistance

|

|

|

4.Clean and healthy for many food and medical applications

|

|

Matters needing attention in the use of printing rubber rollers

The printing rubber roller mainly transfers ink on the offset press. Therefore, the rubber roller must be cleaned carefully during daily cleaning, otherwise the surface layer of the rubber roller and the pigment and resin are easy to oxidize to form a smooth and hard film, which will cause the surface to vitrify and affect the ink transfer. If it is often cleaned and not clean, the surface of the rubber roller will be uneven over time and affect its use. Therefore, the rubber rollers should be cleaned and stored for later use when the machine is stopped.

In the offset printing operation, the ink is emulsified due to "large water and large ink", forming a hydrophilic foundation on the smooth rubber roller, making it deinking. The solution is to shovel the emulsified ink, wash the deinking rubber roller with gasoline, mix and polish with 5% sodium hydroxide aqueous solution and pumice powder, and also deal with the metal roller (or hard roller) accordingly. The hard roller can also be polished with fine water sand under the water sprinkling state. Be careful not to stay in the same place, otherwise it will damage the rubber roller. The fundamental method is to control the pH value of the hopper liquid to improve the ink and wash balance.

The rubber roller has been used for a long time and is aging, coupled with the erosion of chemicals, causing the rotten glue to lose "slag". It is best not to use such a rubber roller, otherwise it will seriously affect the printing quality.

In order to ensure that the production and printing quality are not affected, spare ink rollers must be provided, but do not store too much to avoid aging. The storage environment of the rubber roller is the same as the blanket. In addition, the rubber roller should be set up straight at the journal, and the surface should not be in contact with each other or with other objects to avoid deformation of the rubber roller.

Rubber rollers should not be stored near large motors and generators. Because the large amount of ozone produced by these equipment will cause the surface of the rubber roller to age and crack.

When the weather is cold, the ink is not evenly printed, and auxiliary materials can be appropriately added to the ink. It is forbidden to use infrared heaters and other equipment to bake the ink rubber rollers to prevent the rubber rollers from oxidizing.