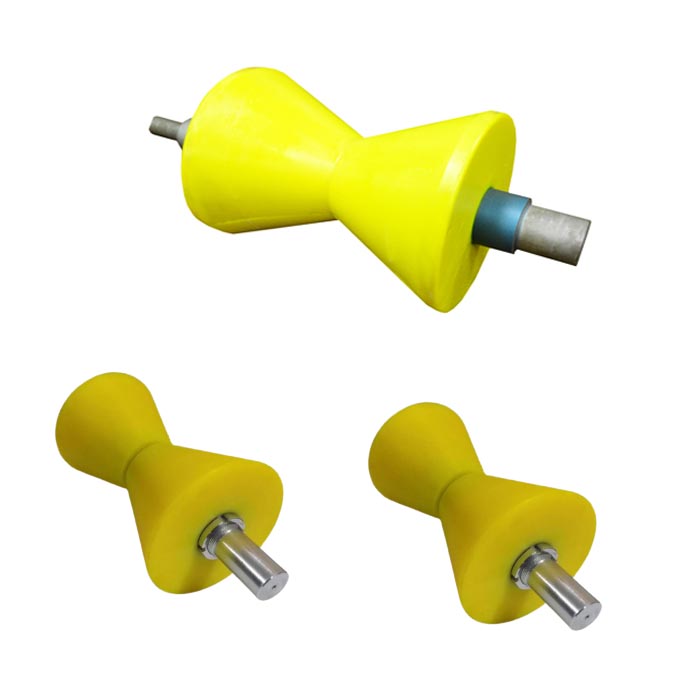

Polyurethane V Roller for oil and gas pipeline

A major pipe manufacturer for Polyurethane V Roller for oil and gas pipeline,it was experiencing frequent failures and shortened life cycle of polyurethane v rollers used in the processing of pipe. When these failures occurred, manufacturing was interrupted while a new polyurethane v roller was put into place. The customer wanted to minimize or shorten the downtime as significant resources were being applied to the replacement. This resulted in high maintenance costs and loss of revenues due to downtime.The customer needed a reliable roller source to decrease cost of replacement parts and to provide the parts quickly.

The rubber roller itself is a rubber product made by vulcanizing the coated rubber layer on the iron core. Its materials include natural rubber, nitrile rubber, silicone rubber, polyurethane and so on. The surface adhesive layer of rubber rollers commonly used in offset printing is generally nitrile rubber, and polyurethane rubber is used for medium and high-grade rubber. The rubber roller is also one of the main components of the offset printing machine’s inking system. It must be in constant contact with water, ink, paper, etc., so it should absorb water to the minimum. Compared with metal rollers, rubber rollers have the characteristics of elasticity, acid and alkali resistance, no rust, etc., have good ink absorption and ink transfer, and are easy to clean, so they are widely used.

However, to a large extent, more emphasis is placed on the life of the rubber roller. In this respect, it needs effective maintenance.