industrial tension rubber roller for Conveyor machinery

The tension roller is an important part used in the strip production line. Its function is to play the role of strip tension to prevent strip deviation, reduce the probability of sheet deformation, and also play a pressing effect during shutdown and belt threading. The general position is at the entrance and exit of the production line. The structural design is generally two-roller, three-roller, four-roller and other structures. The principle is that the tension of the steel plate is proportional to the number of rollers passing through.

The principle requirement for the use of rollers is that the steel plate should not be permanently deformed during use. Therefore, covering rubber is the best way to deal with it. Then the working environment requires that the covering rubber should be wear-resistant, pressure-resistant and tear-resistant. In actual customer application, Lianxing tension roller has a hardness between SHA75-90, a tensile strength of more than 40Mpa, a breaking rate of 350%-1000%, and a wear resistance of more than All types of rubber, with super high strength at high hardness, meet the production requirements and reduce production costs.

To sum up, the requirements of the working environment of the strip tension roller in actual use determine the use effect of the tension roller, so a good product still needs to be tested and affirmed in use.

|

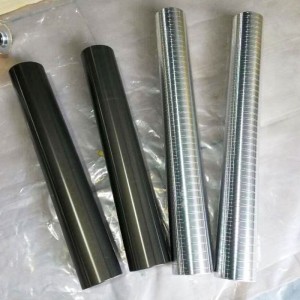

Decai Steel Roller and Rolls Specification

|

|

|

Size

|

Any Size

According To Customer's Drawing,540*1510 is avaliable

|

|

Material

|

45# steel with plating,stainless steel

|

|

Hardness

|

50-70 degree

|

|

Tolerance

|

0.2mm

|

|

Types

|

Mirror roll, chrome plated, anilox roll |

|

Application Machine

|

industrial machine, printing machine and packaging machines and so on

|

|

Features of rubber roller |

1.Ozone and Chemical resistance

|

|

2.Anti-aging, good flexibility, good elasticity

|

|

|

3.Excellent oil resistance

|

|

|

4.Clean and healthy for many food and medical applications

|

|