FREE SHIPPING ON ALL BUSHNELL PRODUCTS

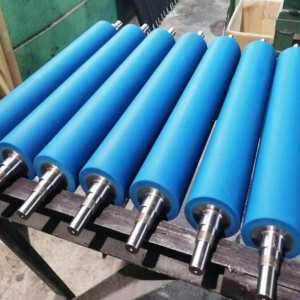

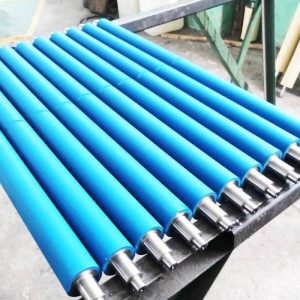

rubber roller for plastic polyurethane rubber roller rolls

Polyurethane rubber printing roller body has sufficient surface viscosity. Therefore, the rubber roller has good ink transfer and inking performance in the printing process, and good ink performance can ensure a certain quality of printing.

The maintenance of the printing rubber roller is as follows:

1. After the production operation is completed every day, the rubber roller should be carefully cleaned and washed twice.

2. Designated chemical preparations, such as industrial alcohol, must be used to clean the printing rubber roller, and corrosive solvents cannot be used.

3. For the protection of the surface of the printing rubber roller, wrap it with newsprint and place it in a ventilated and dark place.

De cai Honorise New Material Co., Ltd.

MB/Wechat/Whatsapp:+0086-13456489912