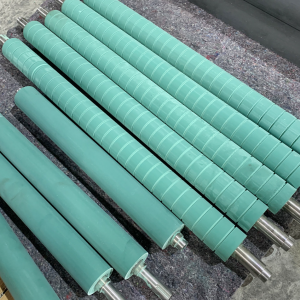

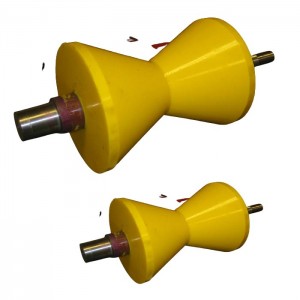

Mechanical rubber roller for Printing machine accessories

As an indispensable accessory of the offset printing machine, the rubber roller has a great influence on the printing quality of the product. It can be said that only good rubber rollers can print products. Therefore, how to scientifically, correctly and reasonably use and maintain the printing rubber roller is a production skill that printing operators should master. It is of great significance to improve production efficiency and ensure printing quality.

|

Decai Rubber Roller Specification

|

|

|

Size

|

Dia:10MM-670MM;

Length:50MM-8200MM

According To Customer's Drawing

|

|

Material

|

NBR,Silicone,Rubber,Polyurethane,NR,PU FFPM,ETC,EPDM

|

|

Hardness

|

18A-100D

|

|

Tolerance

|

0.05mm

|

|

Color

|

yellow,Black, orange,green or custome required

|

|

Core Material

|

stainless steel,45#steel or aluminum

|

|

Application Machine

|

industrial machine, printing machine and packaging machines and so on

|

|

Features of rubber roller |

1.Ozone and Chemical resistance

|

|

2.Anti-aging, good flexibility, good elasticity

|

|

|

3.Excellent oil resistance

|

|

|

4.Clean and healthy for many food and medical applications

|

|

Generally speaking, rubber rollers should be stored in a warehouse with a temperature of 10-35°C and a relative humidity of 50-80%. If the temperature is too high or too low, it will cause thermal cracking or thermal cross-linking of the rubber, which will cause the rubber surface to age, harden, lose its due elasticity, and crack, resulting in a decrease in wear resistance. The air will cause the roller core to absorb moisture and rust.

Since the rubber roller is covered with rubber, during transportation and storage, it should be avoided from direct sunlight, drenched in rain and snow, contact with acids, alkalis, oils and organic solvents, and should be kept 2m away from radiant heat sources.

Do not place it under strong light and ultraviolet light. In addition to directly causing the rupture and cross-linking of the rubber molecular chain, the rubber generates free radicals due to the absorption of light energy, which initiates and accelerates the oxidation chain reaction process. Ultraviolet light acts as heating. Therefore, it is necessary to cover the circumference of the rubber roller with thick paper and black plastic cloth to avoid light, otherwise the rubber surface will be aged, discolored, cracked, etc., which will reduce the service life of the rubber roller and affect the quality of printed products.