Custom in mould printing IML plastic priting label

Product Description

In-mold labeling is a new label packaging form that is different from the traditional direct screen printing, heat shrinkable labels and self-adhesive labels. In-mold labeling is mainly used for blow molding and injection molding products of PP, PE, PET and other materials. That is, put the printed in-mold label into the blowing and injection molding cavity before blow molding and injection molding. When the mold is closed for blowing and injection, the high temperature and high pressure in the mold make the in-mold label special The viscose is melted and melted into the surface of the bottle body or injection molded part. When the mold is opened, a beautifully printed bottle body or injection part is completed at one time.

The term "in mold labeling" (IML) is directly derived from the technique: a preprinted polypropylene (PP) label is placed in a mold that has the shape of the end product, e.g. the shape of a butter tub. Then the molten PP is added to the mold, fuses with the label and -while curing- takes the shape of the mold. Result: label and packaging become one.

IMDECOL designs tailor-made IML Side Entry Robotic Systems to achieve the customer’s goals in the most efficient way.

Our Advantages

1.Strong design group for all kinds of design and pattern;

2. All raw material prepared inspection before production;

3.Printing Ink : Made DIC by Japan manufacture;

4,.Glue : Strong adhesive by South Korea supplier;

5.All the printing color are measured and checked by Al and Computerized;

Specification

| Product name | Custom in mould printing IML plastic priting label |

| Size | As per customer's requirement |

| Material | BOPP/OPP |

| Surface & performance | Glossy, matte, orange peel etc. metallized silver & gold; scrub, laser, colored light etc. |

| Color | Accept customized |

| Printing | Gravure printing |

| Thickness | 18-110 micron , as per customer's requirement |

| Shape | in roll or pieces, size according to the customer's requests |

| Application | PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc |

| Packaging | PE bag + carton + packing belt + plastic pallet |

| Certification | SGS, FDA, ISO |

| Sample service | Acceptable |

| MOQ | 1000square meter (pcs depond on your product size ) |

| warranty | 1 year |

| production time | cylinder making 5-7 days. label making 5-7 days |

| Payment | T/T, Western Union, L/C, Ali accruance pay ;50% deposit and balance before shipment |

| shipment | By air/ Express or by Sea, up to clients |

Feature

Production Process

- 1: Design

- 2: Making plate/cylinder<about need spend 7 days>

- 3: Prepare raw material

- 4: Prining<about 3 days>

- 5: lamination<3-5 working day>

- 6: Cutting<3-5 working days>

- 7: Cutting small sample and ship to customer test cutting size

- 8: QC

- 9: Packaging

- 10: Delivery

Packing and Shipping

1.Carton

2.Pallet

3.As customers’ requirement We not only use customized wooden cases, also identify the marking of impact resistant. Waterproof warning and professional packaging clerk will confirm the transport packaging. For packaging and transportation of forged steel roller, grooved steel roller, pressed steel roller, roll assembly, stainless steel roller, steel rollers for glass annealing.

Our company profile

Application Field

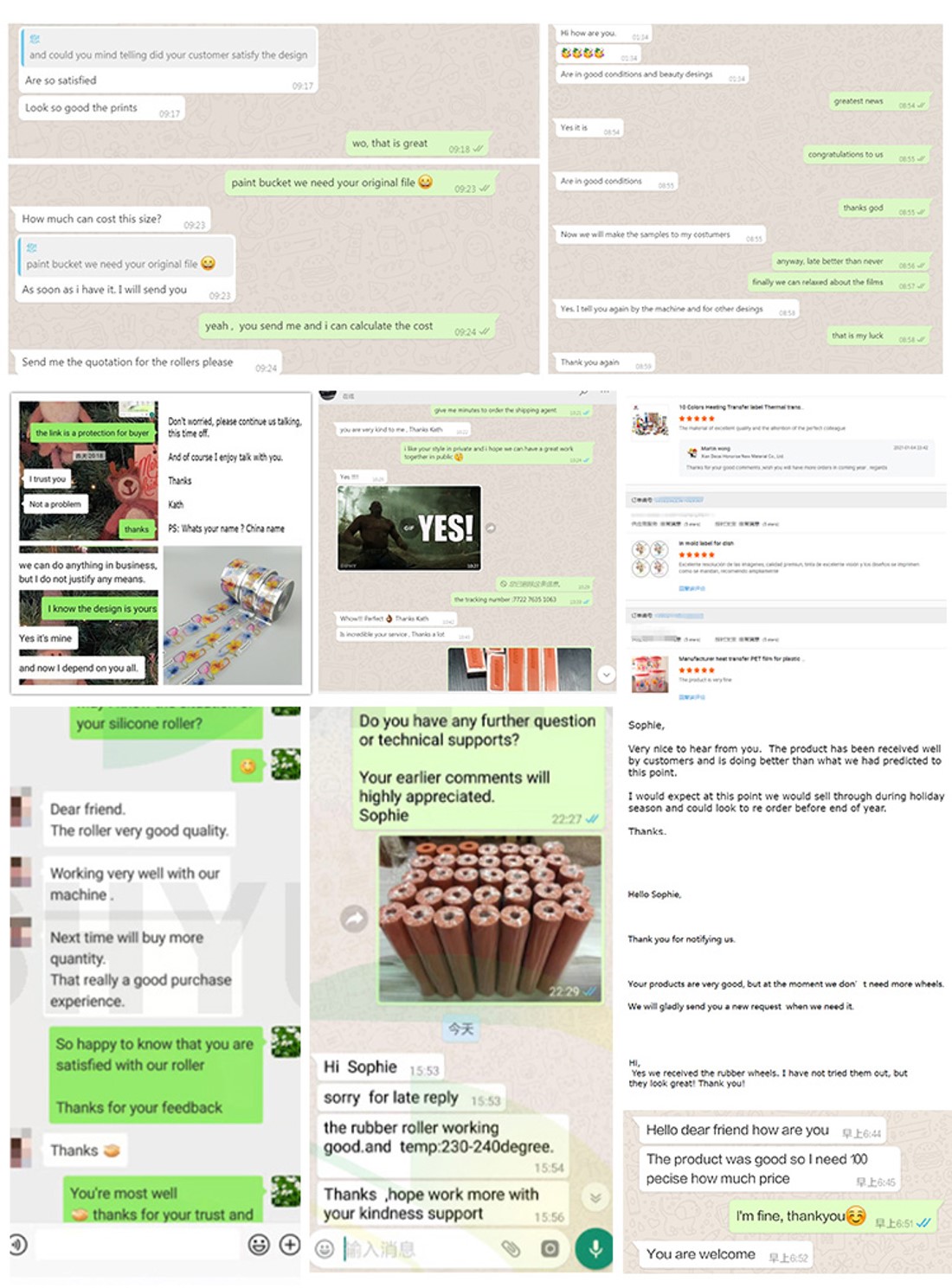

Feedback

FAQ

Q: What is "IML" ?

The term "in mold labeling" is directly derived from the technique: a preprinted polypropylene (PP) label is placed in a mold. Then the molten PP is added to the mold. It fuses with the label, and while curing, takes the shape of the mold. Effect: label and injection product become one.

Q: What makes IML unique?

1): Eco friendly 2): Strong and hygienic 3): Maximum print quality 4): Shorter production time 5): Quick design changeovers 6): Wide range of look and feel options

Contact Us

WhatsApp

0086-17779025926

Wechat:

0086-17779025926

labelprint02_vip@126.com