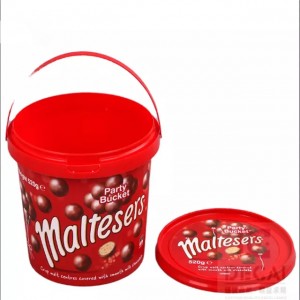

China PP in Mold Label Glossy Iml in Mold Paper for Container Jars

What is IML?

This mould has the shape of the end product, e.g. the shape of a butter tub.

Then the molten PP is added to the mould. It fuses with the label, and while curing, takes the shape of the mould.

The offset printing technique ensures high-resolution images. Besides, you can decorate all the sides of a container with one

single label.

In mould labels resist humidity and big changes in temperature: the best solution to decorate plastic containers for frozen and

refrigerated products! In mould labels are also scratch resistant, cannot crack and are not susceptible to wrinkles.* Shorter production time and lower production costs

During the in mould labeling process containers are produced and decorated in one single step. Storage of blank containers

becomes unnecessary, storage and transport costs belong to the past.

* Environmentally-friendly

In mould labelling saves the environment: the packaging and the label consist of the same material and can therefore be fully

recycled.

* Wide range of look & feel options

The same plastic packaging product can be decorated with a wide range of different materials, inks an lacquers. This allows you

to differentiate your product on the shelf.

* Quick design changeovers

It only takes a shift from one label design to another on your IML automation to make a quick changeover. There is almost no

production loss during the start-up of a new design.

Our in mould label / in mold label / IML is printed by rotogravure, the inks that we used is friendly to environment. The printing effect is vivid, and it is scratch resistance. Suitable for plastic (PP, ABS, AS, PE, PET, PVC ), metal, wood, bamboo, leather etc.

Our Advantages

In mold labeling offers several major advantages:

Maximum print quality

The offset printing technique ensures high-resolution images. Besides, you can decorate all the sides of a container with one single label.

Strong and hygienic

In mold labels resist humidity and big changes in temperature: the best solution to decorate plastic containers for frozen and refrigerated products! In mold labels are also scratch resistant, cannot crack and are not susceptible to wrinkles.

Shorter production time and lower production costs

During the in mold labeling process containers are produced and decorated in one single step. Storage of blank containers becomes unnecessary, storage and transport costs belong to the past.

Environmentally-friendly

In mold labeling saves the environment: the packaging and the label consist of the same material and can therefore be fully recycled.

Wide range of look & feel options

The same plastic packaging product can be decorated with a wide range of different materials, inks an lacquers. This allows you to differentiate your product on the shelf.

Quick design changeovers

It only takes a shift from one label design to another on your IML automation to make a quick changeover. There is almost no production loss during the start-up of a new design.

Features

1.Environmental protection printing,meet the requierment of international non-toxic standard.

2.Four color process printing design finish in one time,no need for the color register.

3.Simple transfer equipment with vivid printing effect.

4.Strong covering power and good adhesive.

5.High gloss,high image definition,toxic free In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of heat transfer printing film for plastic,pe plastic film, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Production Process

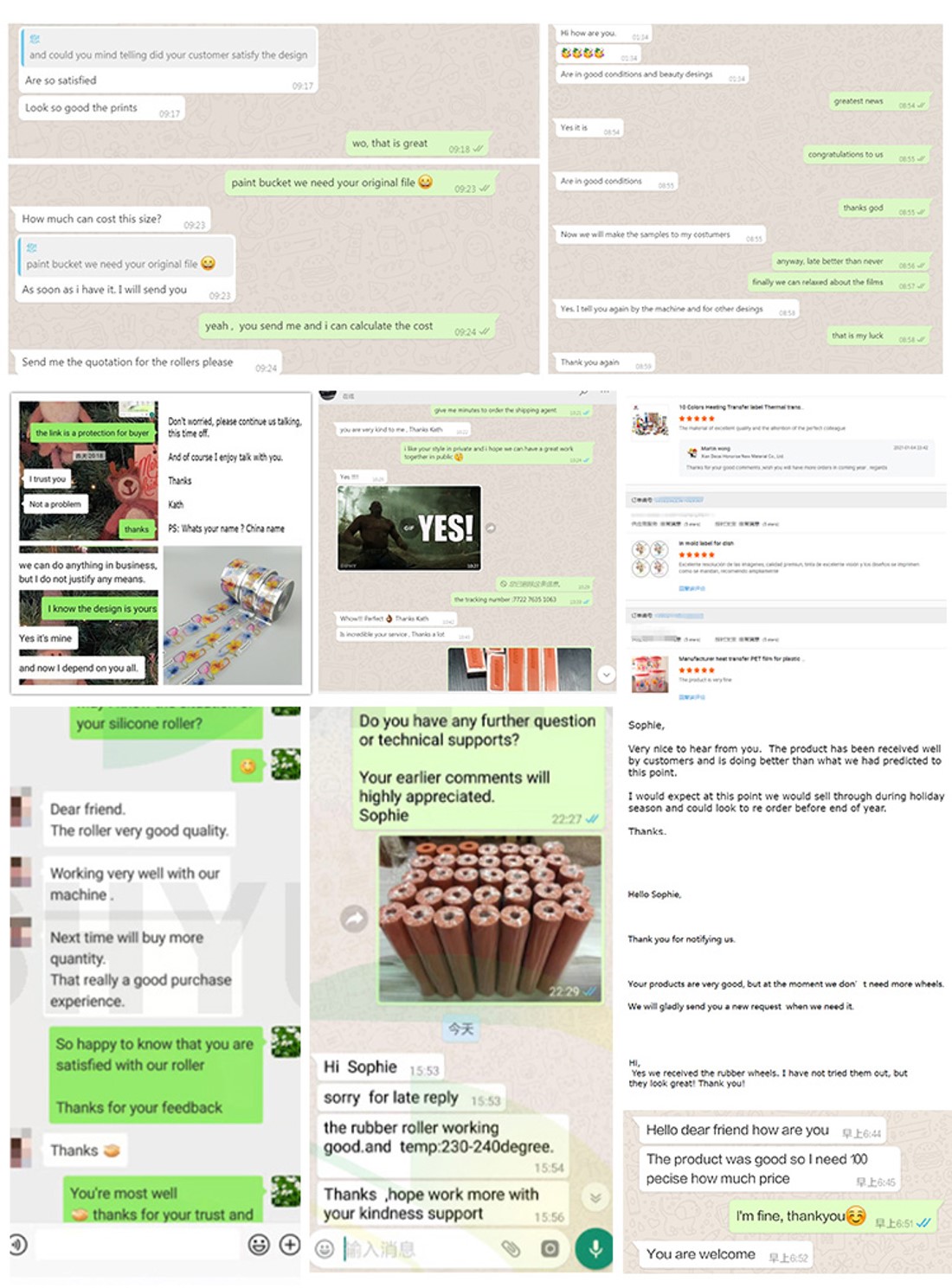

Feedback

Contact Us

WhatsApp

0086-17779025926

Wechat:

0086-17779025926

labelprint02_vip@126.com