Custom Plastic IML label sticker in mould labelling companies

Product Description

In-mould labelling is the use of paper or plastic labels during the manufacturing of containers by blow molding, injection molding, or thermoforming processes. The label serves as the integral part of the final product, which is then delivered as pre-decorated item.

Our customers consistently find that in-mold labeling is a cost-effective solution for decorating plastic containers. It removes the need for post-mold labeling, eliminating costly bottlenecks in production and requiring less manufacturing floor space.

In-mold labels work well in either injection mold, blow mold or thermoforming applications, providing the ultimate ‘no-label’ look even on unique container shapes. These labels provide superior graphic reproduction, with a high degree of product security because of the lack of delamination. In-mold film labels are 100% regrindable and recyclable, which is increasingly important considering today's level of environmental awareness. They also allow for quick design changeovers.

What's the IML in mold label?

Our label used widely for packing of food household articles and container .we will offer u the solution for the whole package of in mold label including glossy ,matt ,orange peel ,foil ,transparent ,and many other special effect .

invisible, as if the graphic is printed on the surface of the bottle. The use of in-mold labels eliminates the need for labeling machines.

Feature

1: MOQ: 1000 square meters

2: We can free design for you,support more fashionable design

3:We can accept customization

4:We can support your reasonable price,help you make more business in your area.

5::Import DIC inks, brighter color, and perfect performance,

DIC according to the green printing standards, no environmental pollution.

6:We have 23 production line and can offer you prompt delivery time.

7:Good temperature resistance, the injection port will not be black or broken

8:Free samples are available anytime when you need

9:100% QC inspection before shipping

10:Complete after-sales service

Advantage

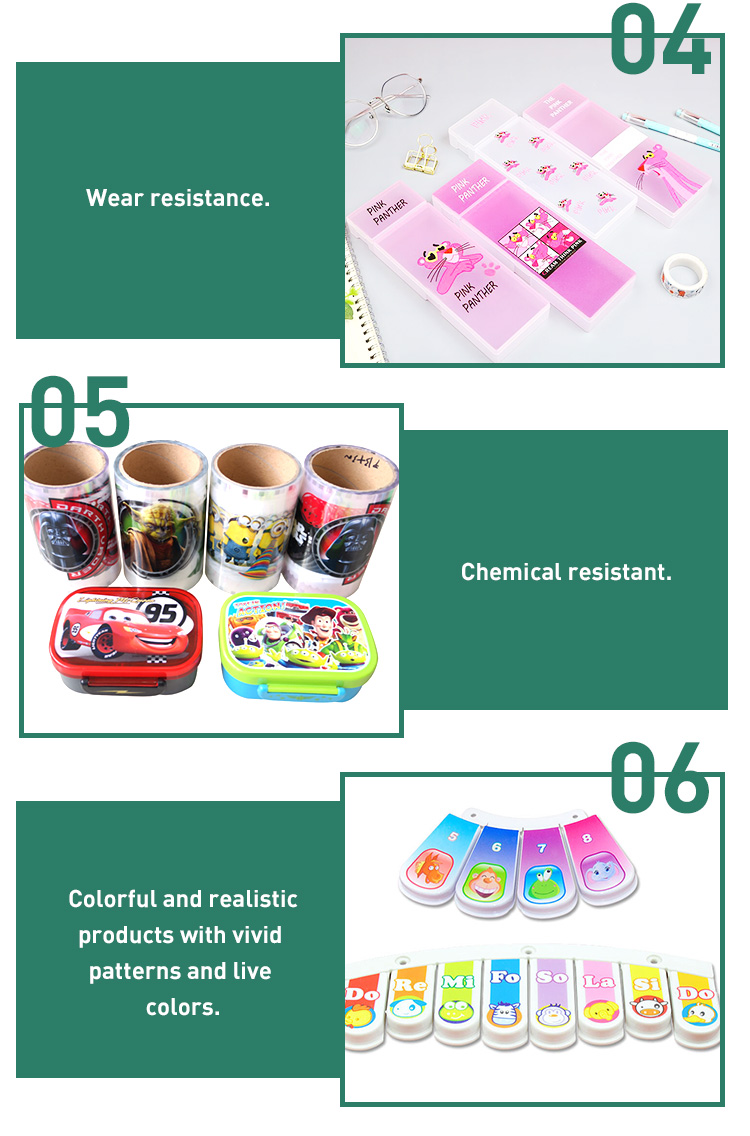

The in-mold decorating (IMD) and in-mold labeling (IML) technology enables design flexibility and productivity advantages over traditional post-molding labeling and decorating technologies, including use of multiple colors, effects and textures in a single operation, long-lasting and durable graphics, and overall labeling and decorating cost reductions. With in-mold labeling (IML) and in-mold decorating (IMD), labeling and decorating are complete in the plastic injection molded process, so no secondary operations are required, eliminating post-molding labeling and decorating labor and equipment costs and time. In addition, design and graphic variations are easily achieved by simply changing to different label films or graphic inserts in the same part run. The use of in-mold decorating (IMD) and in-mold labeling (IML) results in high quality and visually impressive graphics and finished parts. The graphics and labeling are also very durable and long lasting, since they are encapsulated in the resin as part of the finished molded plastic part. In fact, the graphics are essentially impossible to remove without destroying the plastic part. With the right films and coatings, in-mold decorated and in-mold labeled graphics will not fade and remain vibrant for the life of the molded plastic part. In-mold decorating (IMD) and in-mold labeling (IML) advantages include: High quality and visually impressive graphics Ability to use flat, curved or 3D-formed labels and graphics Elimination of secondary labeling and decorating operations and costs, since injection molding and labeling/decorating are accomplished in one step Elimination of adhesives with ability to apply labels and graphics on plastic in one step, unlike pressure sensitive labels Ability to apply labels and graphics on plastic parts and containers’ sides and bottoms all in one step, unlike pressure-sensitive labeling Label inventory reduction Ability to achieve high abrasion and chemical resistance using special hard coatings Easy design variations by changing labeling film or graphic inserts, even in the same part run Continuous image transfers with high positioning tolerances Wide range of colors, effects, textures and graphic options

Specification

| Product name | Cartoon Iml Packaging Label Plastic Cup Film In Mould Label For PP Cup |

| Size | Accept custom |

| Material | Eco-Friendly PP. |

| Printing | Gravure printing |

| Application | PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc |

| Packaging | PE bag + carton + packing belt + plastic pallet |

| Certification | SGS, FDA, ISO |

| Sample service | Acceptable |

| MOQ | 1000SQ.M (Can be negotiated ) |

| warranty | 2 years |

| Delivery time | After receive the payment 15 working days |

| Payment | T/T, Western Union, L/C, Ali accruance pay ;30% deposit and balance before shipment |

| shipment | By air/ Express or by Sea, up to clients |

Payment and Shipment

Production process

Our factory

Feedback

FAQ

1. who are we?

We are based in Shaanxi, China, start from 2018,sell to Mid East(26.00%),Domestic Market(20.00%),Southeast Asia(18.00%),Central America(10.00%),Eastern Asia(10.00%),Eastern Europe(7.00%),South Asia(5.00%),South America(3.00%),Africa(1.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

heat transfer film,hot stamping foil,in mold label,silicone rubber roller,rubber roller

4. why should you buy from us not from other suppliers?

1,Since 1997 more than 20 years experience . 2 . more than 15 production line for Heat transfer and IML production 3 ,Fast repsond ,all the sales are professional sales engineer for control quality .

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,It