Custom PP IML printing label in mold label for injection product

Short description

Custom PP IML printing label in mold label for injection product

In mold labeling refers to the use of a robot to attach the in-mold trademark to the inner surface of the mold when the plastic container is processed by injection molding or blow molding. When the plastic container is blow-molded or injection-molded, the inner surface of the trademark is thermally melted by the raw material itself. It adheres to the outer wall of the container, and the outer printing surface is stable, and can maintain the good effect of trademark printing.

Specification

| Product name | Custom PP IML printing label in mold label for injection product |

| Size | Accept custom |

| Material | Eco-Friendly PP. |

| Surface & performance | Glossy |

| Color | Up to 10 colors |

| Printing | Gravure printing |

| Thickness | 18-110 micron |

| Shape | in roll or pieces, size according to the customer's requests |

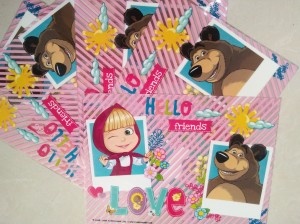

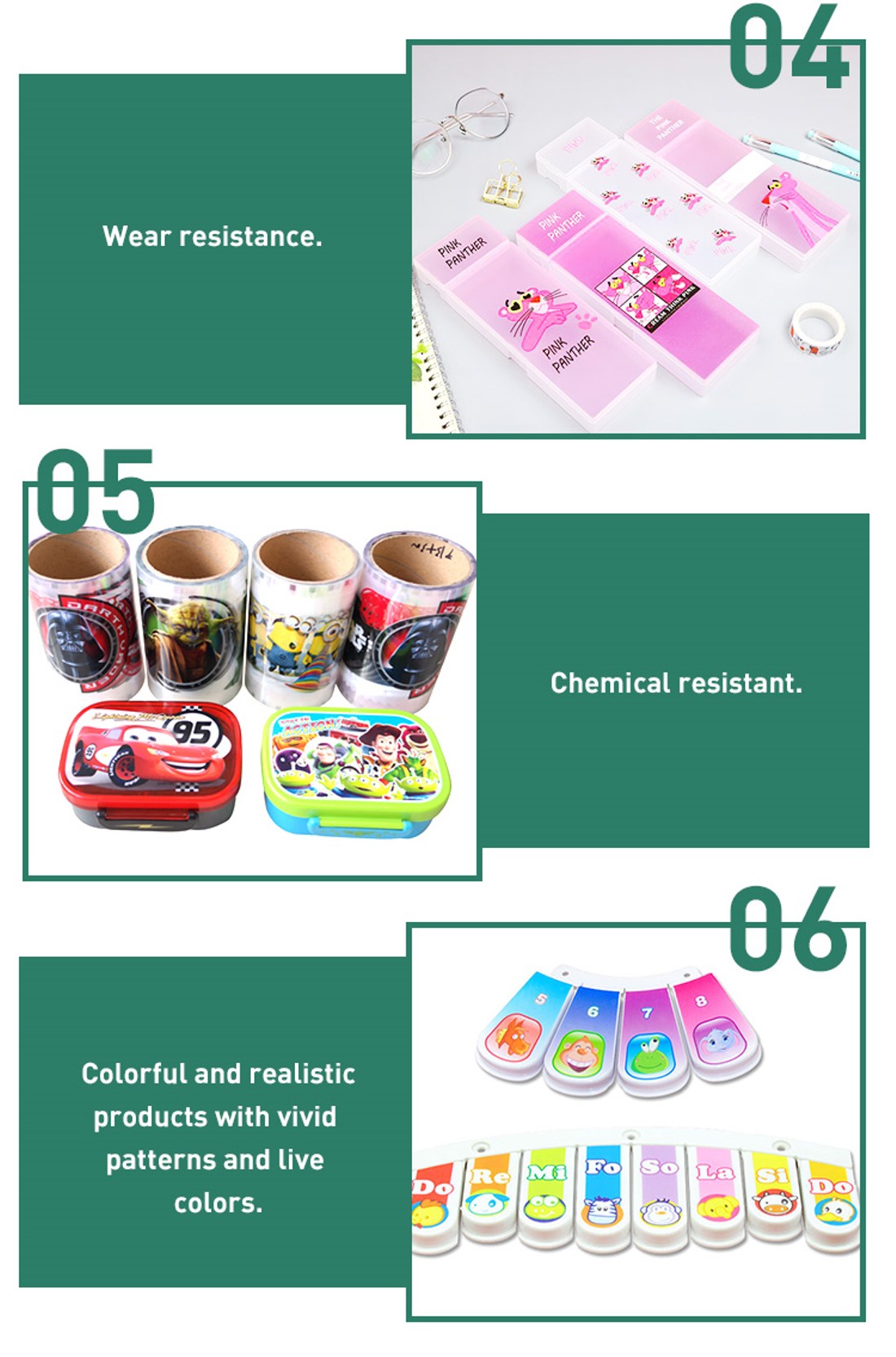

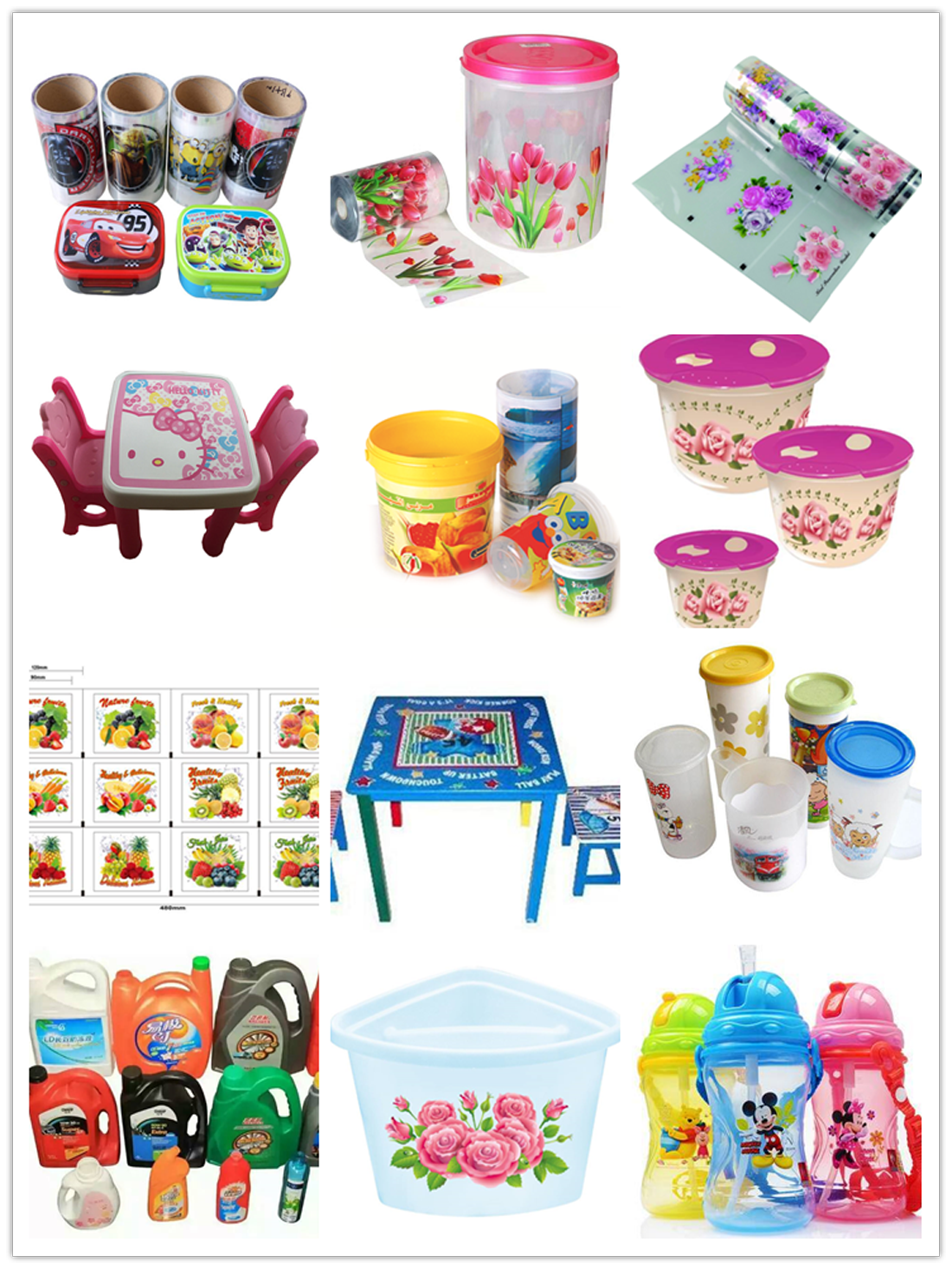

| Application | PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc |

| Packaging | PE bag + carton + packing belt + plastic pallet |

| Certification | SGS, FDA, ISO |

| Sample service | Acceptable |

| MOQ | 1000SQ.M (Can be negotiated ) |

| warranty | 3year |

| Delivery time | After receive the payment 15 working days |

| Payment | T/T, Western Union, L/C, Ali accruance pay ;30% deposit and balance before shipment |

| shipment | By air/ Express or by Sea, up to clients |

| Our Advantages | 1..Free samples are available anytime when you need |

| 2.Free design 24 hours online help you | |

| 3.we have 13 sets printing machine and can offer you prompt delivery time. | |

| 4. import inks ,brighter color and perfect performance |

Advantage

1. Novel and beautiful appearance.

Since the in-mold label and the plastic part are naturally integrated and deformed with the deformation of the bottle body, there will be no blistering or wrinkling. At the same time, the in-mold labeling and printing are exquisite, which can be used for special effects such as laser and aluminum plating, which greatly improves the quality of product packaging;

2. Anti-counterfeiting function.

The in-mold labeling system is relatively complex and reduces the possibility of fraud. This provides a very reliable brand maintenance method for users who pursue quality, quality, and brand plastic packaging products;

3. Safe and environmentally friendly.

Ordinary labels need to wait for the container to be formed before labeling, while the in-mold label and container are formed at one time, thus preventing the possible contamination of the bottle body during the labeling process. Moreover, the in-mold label and the bottle body are completely integrated with the same chemical composition, which can be recycled together, and the recycling rate is high.

4. Not easy to fall off and damage

. The in-mold label has the properties of waterproof, oil proof, mildew proof, acid and alkali resistance, and friction resistance, and it is not easy to be damaged under special conditions.

5. The side walls are reinforced.

The label is embedded in the side wall of the plastic container, which can increase the squeezing strength of the side wall of the container by 20%, so that the label will not separate when the container is warped and squeezed.

6. High efficiency and high benefit.

In-mold label and container forming can be completed at one time, making packaging production faster, and the efficiency of the filling line can be increased by 5% to 20%. Because the manual labeling method after filling is omitted, the cost is reduced.

Labels can be replaced without interrupting production.

The overall comprehensive interest is significantly lower than ordinary labels and direct silk screen printing.

Production process

- 1: Design

- 2: Making plate/cylinder<about need spend 7 days>

- 3: Prepare raw material

- 4: Prining<about 3 days>

- 5: lamination<3-5 working day>

- 6: Cutting<3-5 working days>

- 7: Cutting small sample and ship to customer test cutting size

- 8: QC

- 9: Packaging

- 10: Delivery

Company

Application Products

Feedback