High Quality Iml Labels custom in Mold Labels for Plastic Cups

In mold label Description

In-mold labeling is a new label packaging form that is different from the traditional direct screen printing, heat shrinkable labels and self-adhesive labels. In-mold labeling is mainly used for blow molding and injection molding products of PP, PE, PET and other materials. That is, put the printed in-mold label into the blowing and injection molding cavity before blow molding and injection molding. When the mold is closed for blowing and injection, the high temperature and high pressure in the mold make the in-mold label special The viscose is melted and melted into the surface of the bottle body or injection molded part. When the mold is opened, a beautifully printed bottle body or injection part is completed at one time.

High Quality Iml Labels custom in Mold Labels for Plastic Cups

Mold Labels for Plastic Cups is a technological advancement that has revolutionized the plastic cup manufacturing industry. With mold labeling, plastic cups are produced with high quality and durable labels that seamlessly integrate with the cups, making them more attractive to customers. This technology has made it possible for plastic cup manufacturers to produce high-quality cups in a cost-effective manner.

The use of mold labels has greatly improved the appearance and durability of plastic cups. Before the introduction of this technology, plastic cups had labels that were easily scratched off and faded over time, making them look old and unattractive. With mold labeling, plastic cups look more attractive and the labels are more durable, making them ideal for long-term use.

Another great benefit of mold labeling for plastic cups is that it is eco-friendly. Traditional labeling methods such as screen printing and pad printing generate a lot of waste and use up a lot of energy. However, mold labeling does not result in waste and is a more energy-efficient process. With mold labeling, plastic cup manufacturers can produce cups that are more environmentally friendly and sustainable.

In conclusion, mold labeling has brought about immense benefits to the plastic cup manufacturing industry. It has improved the appearance and durability of plastic cups while also being sustainable and environmentally friendly. Plastic cup manufacturers can now produce high-quality cups at a lower cost and with less waste. The future is bright for the plastic cup manufacturing industry, thanks to mold labeling.

Our Advantages

1.Strong design group for all kinds of design and pattern;

2. All raw material prepared inspection before production;

3.Printing Ink : Made DIC by Japan manufacture;

4,.Glue : Strong adhesive by South Korea supplier;

5.All the printing color are measured and checked by Al and Computerized;

Specification

| Product name | High Quality Iml Labels custom in Mold Labels for Plastic Cups |

| Size | As per customer's requirement |

| Material | BOPP/OPP |

| Surface & performance | Glossy, matte, orange peel etc. metallized silver & gold; scrub, laser, colored light etc. |

| Color | Accept customized |

| Printing | Gravure printing |

| Thickness | 18-110 micron , as per customer's requirement |

| Shape | in roll or pieces, size according to the customer's requests |

| Application | PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc |

| Packaging | PE bag + carton + packing belt + plastic pallet |

| Certification | SGS, FDA, ISO |

| Sample service | Acceptable |

| MOQ | 1000square meter (pcs depond on your product size ) |

| warranty | 1 year |

| production time | cylinder making 5-7 days. label making 5-7 days |

| Payment | T/T, Western Union, L/C, Ali accruance pay ;50% deposit and balance before shipment |

| shipment | By air/ Express or by Sea, up to clients |

Production Process

- 1: Design

- 2: Making plate/cylinder<about need spend 7 days>

- 3: Prepare raw material

- 4: Prining<about 3 days>

- 5: lamination<3-5 working day>

- 6: Cutting<3-5 working days>

- 7: Cutting small sample and ship to customer test cutting size

- 8: QC

- 9: Packaging

- 10: Delivery

Packing and Shipping

Our company profile

Application Field

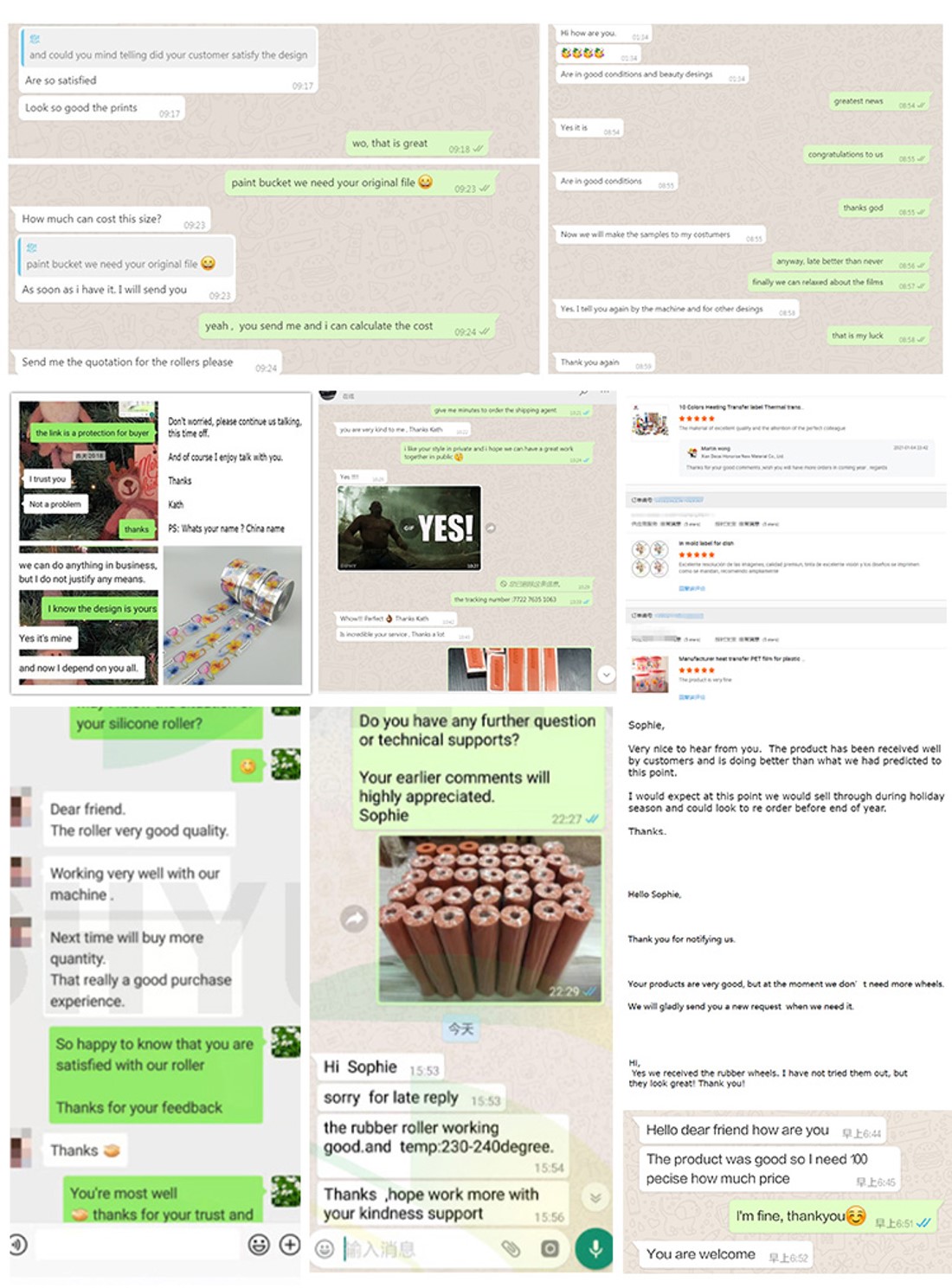

Feedback

FAQ

Q: What is "IML" ?

The term "in mold labeling" is directly derived from the technique: a preprinted polypropylene (PP) label is placed in a mold. Then the molten PP is added to the mold. It fuses with the label, and while curing, takes the shape of the mold. Effect: label and injection product become one.

Q: What makes IML unique?

1): Eco friendly 2): Strong and hygienic 3): Maximum print quality 4): Shorter production time 5): Quick design changeovers 6): Wide range of look and feel options

Contact Us

WhatsApp

0086-17779025926

Wechat:

0086-17779025926

Email

labelprint02_vip@126.com

decai09@rubber-printing.com