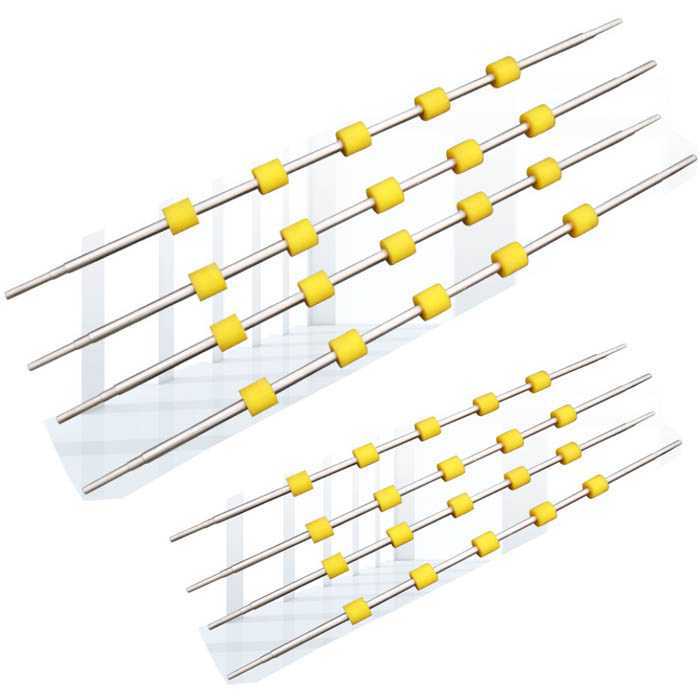

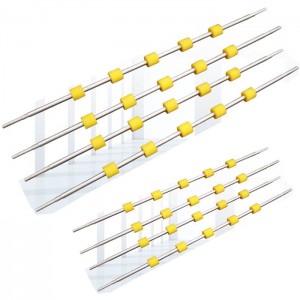

Customized polyurethane roller China Rubber Rollers manufacturers

Polyurethane cots should be paid attention to in use: Polyurethane cots are mainly used to transfer ink on an offset press. Therefore, daily cleaning cots must be carefully cleaned, otherwise it will make the surface layer of cots and pigments, resin oxidation to generate a layer of smooth and hard film, resulting in surface vitrification and affect the transfer of ink. If the frequent cleaning is not clean, the surface of the cots will be uneven and not good to use. Therefore, when the machine is shut down, the rubber roller should be cleaned and put in reserve. In the operation of polyurethane cots, the ink is emulsified because of the "large water and large ink", and the hydrophilic foundation is formed on the smooth cots, so that it is deinked. The solution is to remove the emulsified ink, clean the deinking rubber roller with gasoline, mix and polish with 5% sodium hydroxide aqueous solution and pumice powder, and make corresponding treatment for the metal roller. Hard roller can also be polished with fine water sand in the state of water sprinkling, pay attention to not be fixed in the same part, otherwise it will damage the polyurethane rubber roller. The basic method is to control the pH value of the water bucket and do a good job in ink balance.

Decai Rubber Roller Characteristic

- Production mode: using lean production mode

- Advantages: mold manufacturing, axis production, rubber roller production, integrated management of the entire chemical plating process, no outsourcing process, high efficiency and high quality

- Product sales: 90% of the world is directly or indirectly exported to Europe, America, Japan and other countries and regions

Please store rubber rollers correctly

The correct storage method is: wash it with clean water, then seal it with plastic film, try not to let it come into contact with air, and then put it in a special storage place, and it must not be swayed, affecting its internal mechanical properties and rubber surface the quality of. Internal bearings and shaft heads need good lubrication. The rubber roller manufacturer recommends that in daily situations, the rubber rollers used should be maintained every week, and the rubber surface and internal lubrication should be good enough.

Characteristics of rubber roller :

A. NBR rubber roller

NBR rubber roller can be used as printing roller, food industry rubber roller, dyeing roller in textile printing in dustry and the soft rubber roller for contacting solvent and so on.

Note: The NBR has poor ozone resistance and the operation should be avoided in a high concentration ozone environment during processing.

B. Neoprene roller

Suitable for the soft printing roller, gravure printing roller and so on.

C. Silicone roller

High temperature resistance which can reach 200-250 degrees, and good chemical resistance,but it has low tensile strength.Silicone roller can be used in fabric heat setting, plastic heat setting embossing, calendering, photocopying and so on.

D. Polyurethane rubber

It has outstanding tensile strength wear resistance and crack resistance and good resistance to a variety of solvents.

E. Mirror roller

We generally adopt 45 # steel, alloy steel seamless pipe, precision forgings as the material.The surface of the roller finish degree can reach RA0.01. Mirror processing can ensure the roller surface flatness, balance, non-roundness, coaxial degree meet the customers’requirements.

Q: Are you trading company or manufacturer ?

A: We are a factory integrating R & D, production and sales

Q: How should I get a quote ?

1: Size Specification,such as length,width and thickness

2: Hardness :80-95 Shore A

3: Let me know what machine will you use ?

4: What’s the quantity you need ?

Q:What is your delivery time ?

A: Around 3 days delivery for stock products

Around 15-20 days delivery for customized production.

Q:How do you package the sheet ?

Wooden Case

Q:What is mode of transport ?

A: By express or air or sea.

Q:What’s your payment method ?

A: T/T,Western Union.

Q:Can I get a sample before mass order ?

A: Low cost sample fee + freight charge by yourself;

After you purchase a large quantity, we refund the sample fee

Q:Other Special Support ?

A: Trade Assurance Order By Alibaba