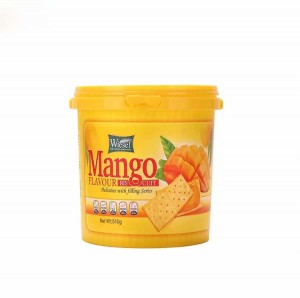

Hot sale 2.5L 70oz plastic cookie food in mold labeling IML container with lid cover

Short description

In-Mold Labeling (IML) containers have become increasingly popular in recent years due to their versatility and aesthetic appeal. IML containers offer a unique packaging solution for a wide range of industries, including food, beverage, and personal care.

IML containers are created by placing a pre-printed label inside the mold before injecting the plastic material. The label becomes an integral part of the container, which results in a seamless and high-quality look. IML containers are very durable and will not peel or fade over time, making them an excellent choice for high-quality branding and product labeling.

One of the significant advantages of IML containers is their ability to highlight the product's features and branding in a visually appealing way. The label's design can be customized and tailored to suit the needs of the product, making it stand out on store shelves and catch the consumer's attention. This translates into increased sales and brand recognition for the product.

Furthermore, IML containers are environmentally friendly because the label and the container are made of the same material, which makes them easy to recycle. This eco-friendliness is increasingly important to consumers who are looking for sustainable packaging options.

In conclusion, In-Mold Labeling (IML) containers provide an excellent solution for various industries looking for high-quality packaging with customizable branding. Their durability, environmental-friendliness, and visually appealing design make them a popular choice for companies looking to stand out on store shelves and attract consumers.

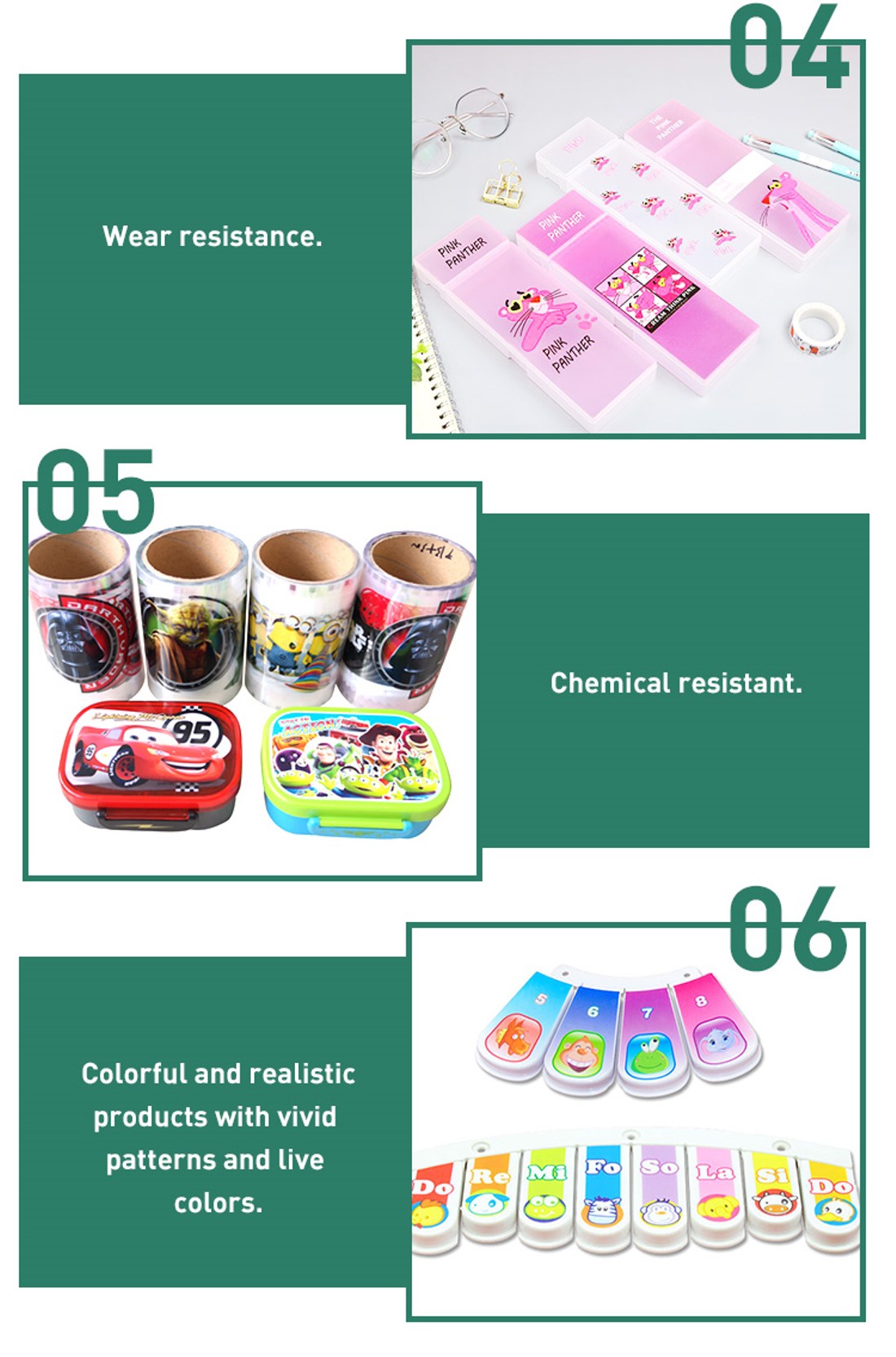

Q: What 's the advantage of IML?

| 1): Eco friendly |

| 2): Strong and hygienic |

| 3): Maximum print quality |

| 4): Shorter production time |

| 5): Quick design changeovers |

| 6): Wide range of look and feel options |

Q: What is "IML" ?

The term "in mold labeling" is directly derived from the technique: a preprinted

polypropylene (PP) label is placed in a mold. Then the molten PP is added to the mold.

It fuses with the label, and while curing, takes the shape of the mold.

Effect: label and injection product become one.

Q:Why are you choose us?

Good factory supplier save your time and money.

Help you to win Market.

1. Over 27 years' manufacturer with ISO certified

2. Creative designer make design for you by free

3. 7-15days short delivery time

4. Free sample & small order are available

5. Full payment refund for quality problem

Specification

| Product name |

Hot sale 2.5L 70oz plastic cookie food in mold labeling IML container with lid cover |

| Size | Accept custom |

| Material | Eco-Friendly PP. |

| Surface & performance | Glossy |

| Color | Up to 10 colors |

| Printing | Gravure printing |

| Thickness | 18-110 micron |

| Shape | in roll or pieces, size according to the customer's requests |

| Application | PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc |

| Packaging | PE bag + carton + packing belt + plastic pallet |

| Certification | SGS, FDA, ISO |

| Sample service | Acceptable |

| MOQ | 1000SQ.M (Can be negotiated ) |

| warranty | 3year |

| Delivery time | After receive the payment 15 working days |

| Payment | T/T, Western Union, L/C, Ali accruance pay ;30% deposit and balance before shipment |

| shipment | By air/ Express or by Sea, up to clients |

| Our Advantages | 1..Free samples are available anytime when you need |

| 2.Free design 24 hours online help you | |

| 3.we have 13 sets printing machine and can offer you prompt delivery time. | |

| 4. import inks ,brighter color and perfect performance |

Production process

- 1: Design

- 2: Making plate/cylinder<about need spend 7 days>

- 3: Prepare raw material

- 4: Prining<about 3 days>

- 5: lamination<3-5 working day>

- 6: Cutting<3-5 working days>

- 7: Cutting small sample and ship to customer test cutting size

- 8: QC

- 9: Packaging

- 10: Delivery

Payment and shipping

Application Products

Company

FAQ

Q:What are the adaptation materials?

A:Plastic (ABS/PC/PP/PET/PVC/PE/PS/EVA/TPU, etc.), silica gel, hardware, glass, wood products, etc.

Q:How about quality control?

A:Has been adhering to the product inspection of the entire shipment, won the praise and trust of customers.

Q:What is the production process?

A:The designed thermal transfer graphics and text are made into electric engraving plates, and these thermal transfer graphics and text are printed on the PET film by a gravure printing machine to make a thermal transfer film, which is then heated and pressed by the thermal transfer machine In the end, the process of transferring the graphics of the thermal transfer film to the substrate.

Q:What kinds of outer packing are there?

A:Carton, snakeskin bags, in addition to support customer special requirements.

Q. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

Q.what can you buy from us?

heat transfer film,hot stamping foil,in mold label,silicone rubber roller,rubber roller

Q. why should you buy from us not from other suppliers?

1, Since 1997 more than 20 years experience .

2 , more than 15 production line for Heat transfer and IML production

3 ,Fast repsond ,all the sales are professional sales engineer for control quality .

Contact

Email:decai09@rubber-printing.com

Whatsapp: 0086-17779025926

Wechat: 0086-17779025926