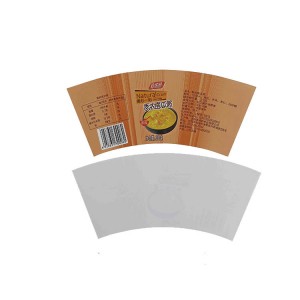

Eco-Friendly In Mold Label Injection Products

Product Description

1.What is in mold label?

In Mold Paper is a new technique for placing Film Film inside an injection mold to decorate the plastic surface.At present, there are two manufacturing methods for IML. One is to make the printed Film Film into a circulating roller and roll belt, install it into injection molding machine and injection mold, and produce the circulating belt in a fully automatic way, like Label affixed to the front die surface.This is called IML(transfer and injection in the mold).

The Film is then printed, formed by Forming machines, then cut and placed in injection molds.This is called IML (injection molding with film in the mold).This film-general can be divided into three layers: base material (usually PET), INK layer (INK),and adhesive material (usually a special adhesive).

When the injection molding is finished, the Film and the plastic are tightly combined into the body through the adhesive effect.

As the PET with the wear resistant protective Film on its positive surface is in the outermost layer, it has the effect of wear resistance and scratch resistance. Its surface hardness can reach 3H, and the more it feels, the brighter it will be.Injection materials for PC, PMMA, PBT and so on.

Feature

Excellent printing performance, suitable for a variety of printing methods.

Fast ink-drying and bright colors.

Orange-peel effect and smooth lines after finished.

Good corona treatment ability, no breach.

Low static, easy for die-cutting.

No mutual adsorption between labels to ensuring smooth labeling of manipulator.

Low weight and high yield.

Good temperature resistance, the injection port will not be black or broken.

Suitable for both of the cup body and the cup cover.

Suitable for labeling of PP resin containers.

Our Advantages

1. Novel and beautiful appearance.

Since the in-mold label and the plastic part are naturally integrated and deformed with the deformation of the bottle body, there will be no blistering or wrinkling. At the same time, the in-mold labeling and printing are exquisite, which can be used for special effects such as laser and aluminum plating, which greatly improves the quality of product packaging;

2. Anti-counterfeiting function.

The in-mold labeling system is relatively complex and reduces the possibility of fraud. This provides a very reliable brand maintenance method for users who pursue quality, quality, and brand plastic packaging products;

3. Safe and environmentally friendly.

Ordinary labels need to wait for the container to be formed before labeling, while the in-mold label and container are formed at one time, thus preventing the possible contamination of the bottle body during the labeling process. Moreover, the in-mold label and the bottle body are completely integrated with the same chemical composition, which can be recycled together, and the recycling rate is high.

4. Not easy to fall off and damage

4. Not easy to fall off and damage

. The in-mold label has the properties of waterproof, oil proof, mildew proof, acid and alkali resistance, and friction resistance, and it is not easy to be damaged under special conditions.

5. The side walls are reinforced.

The label is embedded in the side wall of the plastic container, which can increase the squeezing strength of the side wall of the container by 20%, so that the label will not separate when the container is warped and squeezed.

6. High efficiency and high benefit.

In-mold label and container forming can be completed at one time, making packaging production faster, and the efficiency of the filling line can be increased by 5% to 20%. Because the manual labeling method after filling is omitted, the cost is reduced.Labels can be replaced without interrupting production.

The overall comprehensive interest is significantly lower than ordinary labels and direct silk screen printing.

Payment and Shipping

Payment:

We are accept: T/T,HSBC,Paypal,VISA,L/C,Master card,Western union,Alibaba trade assurance,as your requirements

Shipping:

We have DHL,FedEx,EMS,TNT,UPS,China post,SF express etc,as your requirements

Company And Feedback

FAQ

1. who are we?

We are based in Shaanxi, China, start from 2018,sell to Mid East(26.00%),Domestic Market(20.00%),Southeast Asia(18.00%),Central America(10.00%),Eastern Asia(10.00%),Eastern Europe(7.00%),South Asia(5.00%),South America(3.00%),Africa(1.00%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

heat transfer film,hot stamping foil,in mold label,silicone rubber roller,rubber roller

4. why should you buy from us not from other suppliers?

1,Since 1997 more than 20 years experience . 2 . more than 15 production line for Heat transfer and IML production 3 ,Fast repsond ,all the sales are professional sales engineer for control quality .

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Italian

Contact information