-

iml static charging generator

iml static charging

high voltage generator

iml download generator -

static electricity machine for iml in mold label add static electric

static electricity machine

for iml in mold label

add static electric -

static generator high voltage electrostatic generator used for iml labels for molding

static generator

electrostatic generator

high voltage electrostatic generator

iml labels for molding -

high voltage generator static generator for packaging labels

High voltage generator

static generator

for packaging labels -

Electrostatic charger generator electrostatic high voltage generator

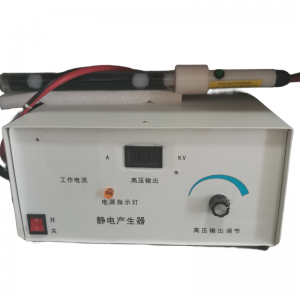

The static electricity generator is an auxiliary machine used to add static electricity to IML. Some IML labels may lose static electricity due to long-term transportation or long-term storage. After adding static electricity with this machine, they can be used. -

Static Generator IML label add static electricity

Static generator is a device that can help add static electricity to IML labels. It can help add static electricity to the IML label that has lost static electricity, so that the label can be attached to the product for injection molding. -

Electrostatic charger generator electrostatic high voltage generator

An electrostatic generator is a device that can help add static electricity to IML labels. After leaving the factory, IML labels may have insufficient static electricity during use due to reasons such as being transported for too long or being stored for too long. In order to avoid label waste, an electrostatic generator can be used to help increase static electricity on the label. -

2024 Easy to Use Iml Static Charging Generation Device for Plastic Film Iml

In-mold labeling (IML) has become a popular choice for labeling plastic films due to its durable, high-quality finish. However, the process of IML printing can sometimes lead to issues with static electricity, which can cause problems for product performance and production efficiency. -

Easy to Use Iml Static Charging Generation Device for Plastic Film Iml

Static charging generation, also known as electrostatic charging, is a fascinating phenomenon that has captured the interest of scientists and researchers for many years. It occurs when two surfaces come into contact and then separate, creating a buildup of electrical charge on their surfaces.

-

Electrostatic generator static charger for in mold label

The static electricity generator is a machine that can release static electricity. The static electricity it releases can help IML labels increase static electricity, thereby improving work efficiency and reducing waste caused by insufficient static electricity in labels and products. -

IML static chargering iml label for pp plastic jar can boxes

An electrostatic generator is a machine used to increase static electricity on IML labels, which can improve work efficiency and reduce label waste. -

Easy to Use Iml Static Charging Generation Device for Plastic Film Iml

IML static generator can be used in manufacturing to reduce waste from production processes. They can be used to electrostatically charge materials, such as plastic pellets or powders, which can then be attracted to surfaces or shaped into desired forms without the need for additional chemical binders or other processing aids.

FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Decai's bronzing, heat transfer silica gel roller and wheel, hot stamping silicone rubber plate(pad)are widely used in stationery, electrical appliances, toys, cosmetics boxes, cigarette packets, wine box wood, stainless steel, glass, paper, leather, soft and hard plastic printing packaging field.