Factory Chemically Resistant NBR Nitrile Rubber rollers for sales

The rubber roller is an important part of the printing machine, which has an important influence on the quality of printed products. The rubber roller has different functions on different types of printing machines. How to choose a high-quality and high-performance printing rubber roller will improve the production efficiency of the printing plant. It is of great significance to meet various production requirements and ensure printing quality. At present, among the rubber rollers used in printing plants, natural rubber rubber rollers and synthetic rubber rubber rollers are more common. High-performance polymer rubber rollers have been gradually accepted by companies with high-quality printing presses and will be used more widely. Polyurethane rubber rollers are one of them.

Large-scale rubber rollers such as large capacity and high belt speed have become the main direction of development. Its core technology is the development and application of rubber roller dynamic analysis and monitoring technology, which improves the operating performance and reliability of the roller. At present, in The main technical indicators used in coal mines have reached the main technical indicators shown in Table 1.

Characteristics of rubber roller :

A. NBR rubber roller

NBR rubber roller can be used as printing roller, food industry rubber roller, dyeing roller in textile printing in dustry and the soft rubber roller for contacting solvent and so on.

Note: The NBR has poor ozone resistance and the operation should be avoided in a high concentration ozone environment during processing.

B. Neoprene roller

Suitable for the soft printing roller, gravure printing roller and so on.

C. Silicone roller

High temperature resistance which can reach 200-250 degrees, and good chemical resistance,but it has low tensile strength.Silicone roller can be used in fabric heat setting, plastic heat setting embossing, calendering, photocopying and so on.

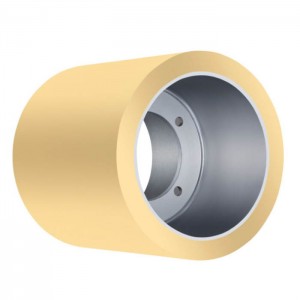

D. Polyurethane rubber

It has outstanding tensile strength wear resistance and crack resistance and good resistance to a variety of solvents.

E. Mirror roller

We generally adopt 45 # steel, alloy steel seamless pipe, precision forgings as the material.The surface of the roller finish degree can reach RA0.01. Mirror processing can ensure the roller surface flatness, balance, non-roundness, coaxial degree meet the customers’requirements.

Q: Are you trading company or manufacturer ?

A: We are a factory integrating R & D, production and sales

Q: How should I get a quote ?

1: Size Specification,such as length,width and thickness

2: Hardness :80-95 Shore A

3: Let me know what machine will you use ?

4: What’s the quantity you need ?

Q:What is your delivery time ?

A: Around 3 days delivery for stock products

Around 15-20 days delivery for customized production.

Q:How do you package the sheet ?

Wooden Case

Q:What is mode of transport ?

A: By express or air or sea.

Q:What’s your payment method ?

A: T/T,Western Union.

Q:Can I get a sample before mass order ?

A: Low cost sample fee + freight charge by yourself;

After you purchase a large quantity, we refund the sample fee

Q:Other Special Support ?

A: Trade Assurance Order By Alibaba