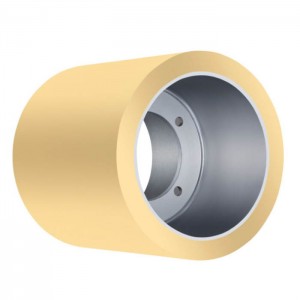

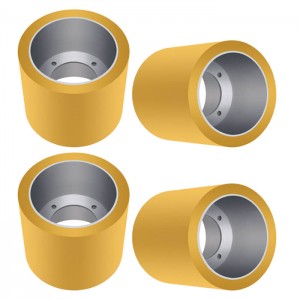

Feather dehusking Rice Mill Rubber Roll Rice Rubber Rollers Manufacturer from China

Specializing in the production of husked rubber rollers for more than 30 years, using some materials produced in the United States, Japan, and Taiwan, it is fully equipped, has a domestic reliable rubber roller production line, a mature technical team, rich experience, and complete testing methods. Seiko production, to ensure reliable quality, with the tenet of quality first and customer first, we will provide you with multi-faceted services for rubber rollers. The annual production of various husked rubber rollers is 1 million. The various types of grain hulling rubber rollers produced are of good quality and good wear resistance.

Size:

4inc,6inch,7inch,8inch,10inch,12inch,14inch,20inch

Feature:

Resiliency Temperature Resistance Durability, Flexibility And Capacity To Withstand All The Mechanical Stress And Forces

Detailed Information:

the machine compared with the iron drum core, and easy to install.

Remarks:

1. The wheel hub of the hulling rubber roller can be made of cast iron core, aluminum core, steel tube core according to your requirements.

2. According to your requirements, the material of the hulling rubber roller can be SBR (styrene butadiene rubber) or NBR (nitrile rubber) or PU (polyurethane).

3. The hardness of the outer layer of the rice hulling rubber roller ranges from 90 degrees to 95 degrees. The suitable hardness of the rice hulling rubber rollers can be customized according to the climate, rice types and other needs.

4. If you need various specifications of rice hulling rubber rollers, please send us your samples or detailed information, and we will provide you with special information.

Attention:

1.Handle carefully during the transportation.

2.Store in dry place,away from Acid,Alkali,Salt,oil and dirty,forbidden to put under sun for long time.

3.Take sands away from the paddy,keep paddy dry and cleaning when using the rollers.

4.Two rollers should be at the same level,the space must be equal.

5.The paddy inputting should be keep the blance.

6.Keep the rate of the re-hulling under the limited.

7.Don't make the machine work for a long time,in case effecting the hulling capacity.

8.The surrounding temperature is better under the 50°C.

9.Change the fast and slow roller at a certain time.

DECAI Company Introduction

Decai Honorise is a leading manufacturer of heating transfer field, one-stop service comprehensive enterprise. The products involves the following major aspects:

High-precision hot stamping silicone rubber roller and wheel、gravure printing rubber roller and various industrial rubber rollers.

Thermal transfer film labels and in-mold labeling.

Heat transfer machine and hot stamping machine.

Integrating production, sales and R&D together. In strict accordance with printing industry standards for production and management. We're own scientific formula, precise processing methods and superb grinding technology, we provide high-quality products with advanced production equipment and strong technical force.