Glossy metallic in Mold Label IML label for 20L Paints Buckets

Glossy metallic in Mold Label IML label for 20L Paints Buckets

In today's competitive market, it's important to have product packaging that stands out and catches the eye of consumers. One way to achieve this is through in-mold labeling (IML) which offers a sleek and professional look to products, especially for 20L paint buckets.

One of the options available with IML is the glossy metallic finish, which gives a premium look to the packaging. It adds a touch of sophistication and elegance, making the product more appealing to consumers. This type of label can be customized in various shades of metallic colors, offering brands the chance to stand out and make a lasting impression on their customers.

The process of IML involves embedding the label into the product itself, ensuring that the label will remain intact and will not peel off or fade away over time. This ensures that the product looks great on the shelf and continues to look great even after being used, providing a positive experience for customers.

Overall, the use of in-mold labeling with glossy metallic finishes provides an excellent opportunity for brands to enhance their product packaging and stand out in a crowded market. It adds value to the product and helps to create a positive image in the minds of consumers.

The process of IML

When using in-mold labeling technology, the pre-printed paper label or plastic film label is placed in the mold, and the label is seamlessly fused to the thermoplastic material during the molding process, thus integrating the production and labeling process, no need for post-labeling. After curing, the container and label will become a single waterproof and scratch-resistant piece.injection label inside an injection mold to decorate the plastic surface.At present, there are two manufacturing methods for IML.One is to make the printed Film Film into a circulating roller and roll belt, install it into injection molding machine and

injection mold, and produce the circulating belt in a fully automatic way, like Label affixed to the front die surface.This is called IML(transfer and injection in the mold). The Film is then printed, formed by Forming machines, then cut and placed in injection molds.This is called IML (injection molding with film in the mold).This film-general can be divided into three layers:

base material (usually PET), INK layer (INK),and adhesive material (usually a special adhesive). When the injection molding is finished, the Film and the plastic are tightly combined into the body through the adhesive effect. As the PET with the wear resistant protective Film on its positive surface is in the outermost layer, it has the effect of wear resistance and scratch

resistance. Its surface hardness can reach 3H, and the more it feels, the brighter it will be.Injection materials for PC, PMMA, PBT and so on.

Product Show

The Advantages of IML

In mold labeling offers several major advantages:

Maximum print quality

The offset printing technique ensures high-resolution images. Besides, you can decorate all the sides of a container with one single label.

Strong and hygienic

In mold labels resist humidity and big changes in temperature: the best solution to decorate plastic containers for frozen and refrigerated products! In mold labels are also scratch resistant, cannot crack and are not susceptible to wrinkles.

Shorter production time and lower production costs

During the in mold labeling process containers are produced and decorated in one single step. Storage of blank containers becomes unnecessary, storage and transport costs belong to the past.

Environmentally-friendly

In mold labeling saves the environment: the packaging and the label consist of the same material and can therefore be fully recycled.

Wide range of look & feel options

The same plastic packaging product can be decorated with a wide range of different materials, inks an lacquers. This allows you to differentiate your product on the shelf.

Quick design changeovers

It only takes a shift from one label design to another on your IML automation to make a quick changeover. There is almost no production loss during the start-up of a new design.

Features

1.Environmental protection printing,meet the requierment of international non-toxic standard.

2.Four color process printing design finish in one time,no need for the color register.

3.Simple transfer equipment with vivid printing effect.

4.Strong covering power and good adhesive.

5.High gloss,high image definition,toxic free In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of heat transfer printing film for plastic,pe plastic film, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Packing and Shipping

Our company profile

Application Field

Application of pet heat transfer film Heat transfer film is suitable for hot stamping on the flat, curved, irregular,cylindrical, and conical surfaces of plastic, metal, leather, ceramics, wood and other products. It is widely used in daily necessities, cosmetics, stationery, toys, building materials, decorative materials, The surface printing and decoration of products in the industries of premium gifts, food packaging, signs, etc. and packaging. Such as the common plastic water cups in our lives, the beautiful heat transfer patterns on them are transferred on the heat transfer film of the water cup.

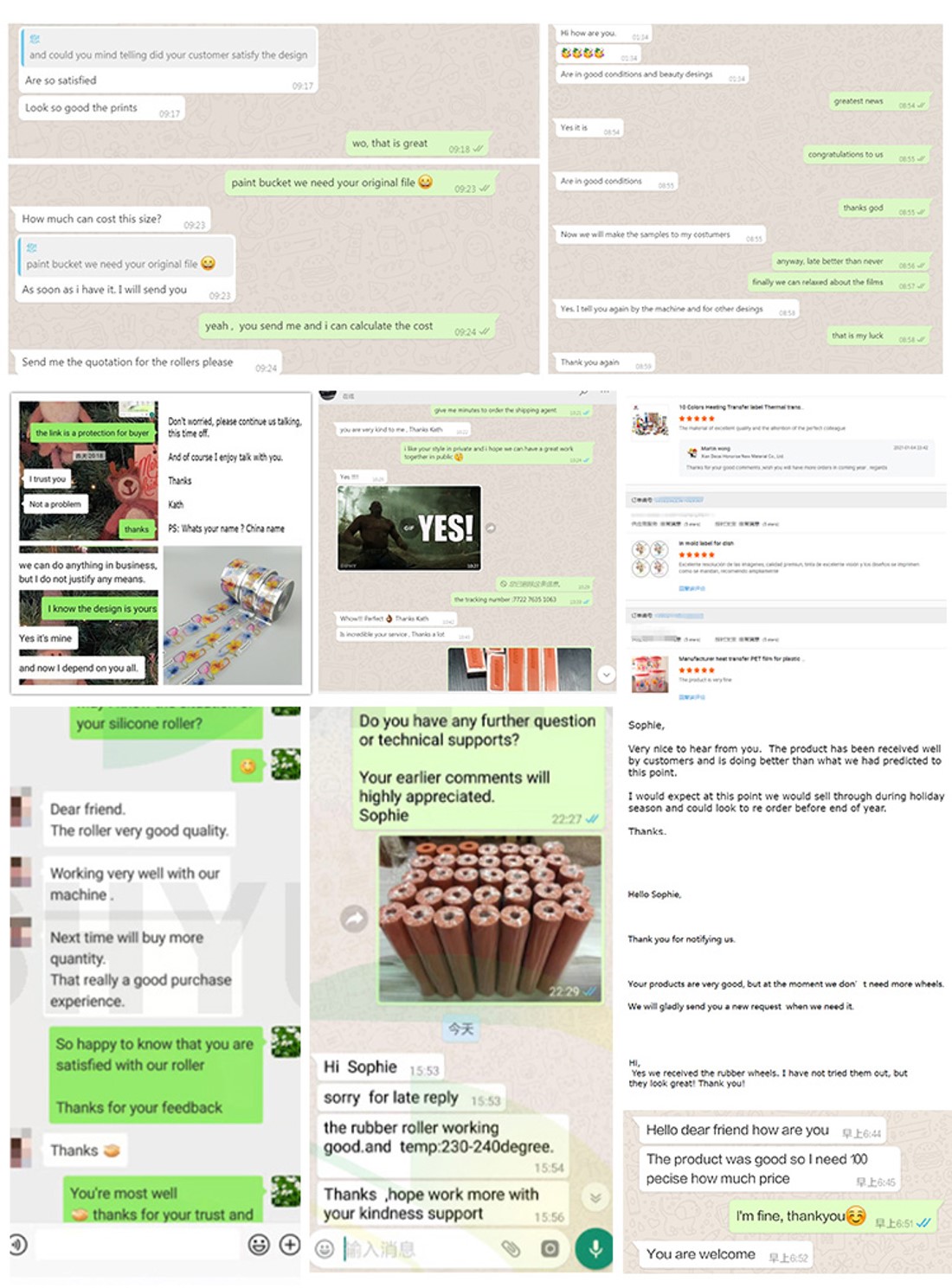

Feedback

FAQ

Q: What is heat transfer printing ?

permanently bonded to a part by the heat and pressure of the heat transfer process. Since heat transfer label are preprinted, multicolor images are transferred to the part in one pass.

Q:Will you sell my patent product to my competitor or others?Is it protected by your company?

Contact Us

WhatsApp : 0086-17779025926

Wechat: 0086-17779025926

Email: labelprint02_vip@126.com