high quality conveyor belt guide roller

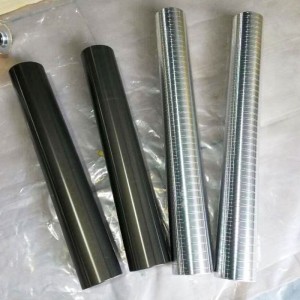

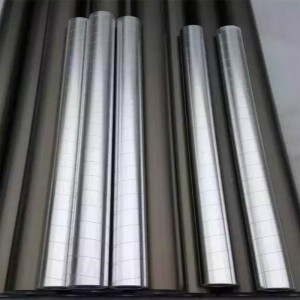

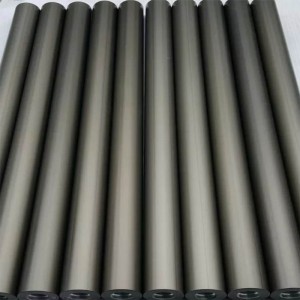

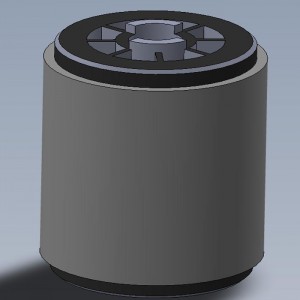

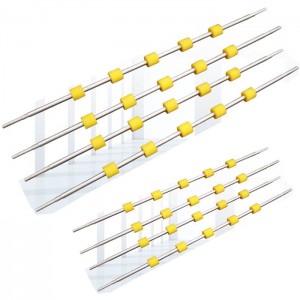

The aluminum guide roller is made of high-quality aluminum alloy material, and is molded into a tube shape with a rib structure inside, which has good scratch resistance, wear resistance and anti-sticking properties. The outer diameter has various specifications such as Φ22m-Φ320mm. All shafts are calibrated by computer dynamic balance, so that the highest accuracy of balance can reach within 5g. Using sophisticated equipment and special tools, the gloss of the roller surface can reach 0.8 or 0.4, and the coaxiality can reach 0.02mm. The shaft end is treated with a special process and matched with imported bearings, so it can operate easily at high speeds. It is suitable for printing, packaging, plastics, papermaking, glass fiber, pharmaceuticals, electronic batteries, textiles and other machinery industries and various coil processing industries.

Aluminum guide roller process introduction

The aluminum guide roller is extruded from high-quality aluminum alloy, with nine built-in ribs and a wall thickness of 5cm for strengthening. The surface treatment is based on user requirements, including ordinary oxidation, hard oxidation, Teflon, etc., to ensure its rigidity and wear resistance Sex. Introduce advanced akshi computer to balance and calibrate to make the balance amount up to 2g or less. Using Taiwan imported precision processing equipment, cutting tools, and measuring tools, the surface roughness of the rollers is 0.8, the coaxiality is 0.02mm, and the reasonable shaft head connection method can easily run freely at any operating speed. transform. The aluminum guide roller has the characteristics of high strength, low resistance, corrosion resistance, light weight, smooth rotation and no rust.

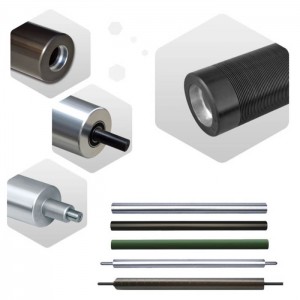

The aluminum guide roller uses precision equipment and special tools for surface finishing, so that the surface is smooth, the coaxiality reaches 0.02mm, all shafts are processed by computer balance correction within 2g, the shaft end is special technology and imported bearings, under high-speed operation, All can operate easily and freely. According to the different needs of the industry, its surface can also be specially treated: sandblasting, netting, Teflon and special hardening treatment HV700, so that it has good scratch resistance and abrasion resistance.

|

Decai Aluminum guide roller Specification

|

|

|

Size

|

Any Size

According To Customer's Drawing

|

|

Material

|

Aluminum |

|

Diamter

|

22-320mm |

|

Length

|

100-6000mm |

|

Anodize

|

HV300/HV700 |

|

Thickness of anodize

|

20-80μm |

|

Type

|

Without shaft/ With shaft/ Through shaft |

|

Surface

|

Smooth/ Cross line/ Center line/ Groove line |

| Smoothness | Ra6.3-0.4 |

| Balancing | G6.3/G2.5 |

With the continuous research and application of advanced technology, the company has made rapid development of its products. It has been committed to the business philosophy of technological improvement and scientific management, with international standards, new technologies, and new equipment to enhance the ability to participate in the fierce market competition.

We specialize in the production of color printing machinery, packaging machinery, various flexible packaging aluminum guide rollers, and our products are sold throughout the country. With excellent quality and good after-sales service system, it is deeply trusted and welcomed by colleagues at home and abroad. Since its inception, we have been winning reputation with quality, creating brand with reputation, and winning market with brand.

We adhere to the tenet of "technological achievements, service leading the market", relying on technological innovation and centering on customer satisfaction. , Continue to provide customers with reliable and cost-effective products, but also firmly believe that in line with strict requirements on product quality, with high-quality products and excellent results to return to the society.