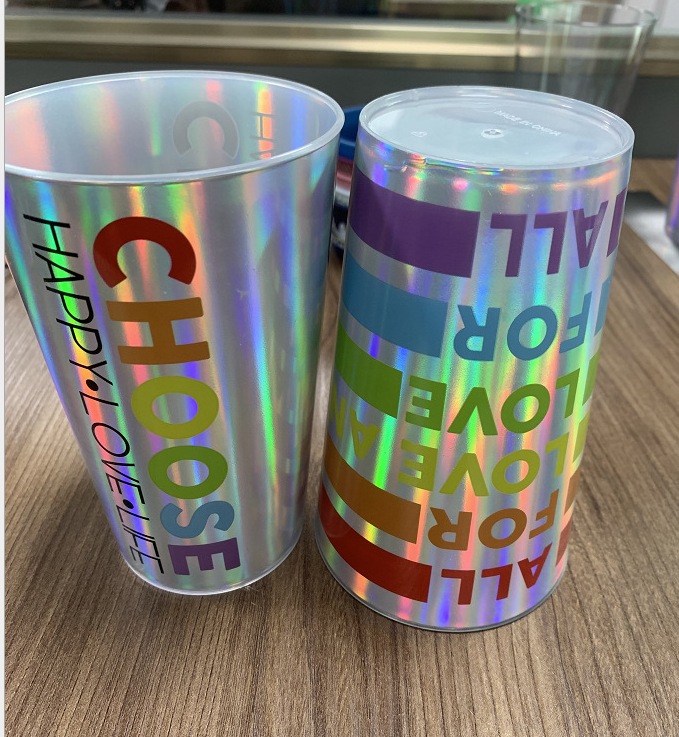

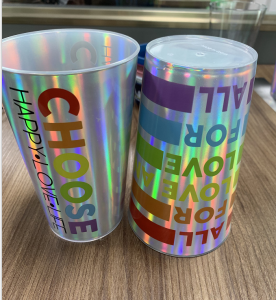

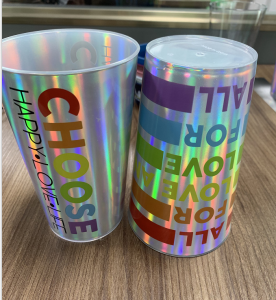

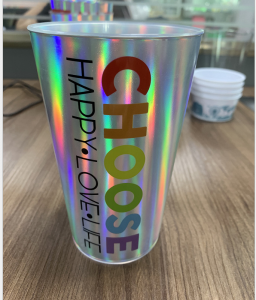

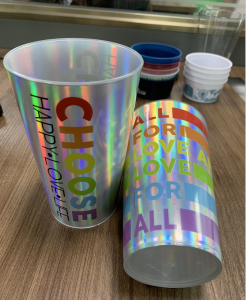

High quality injection mould labeling In-mould labeling cup with full cover labeling for packaging

High quality injection mould labeling In-mould labeling cup with full cover labeling for packaging

When using in-mold labeling technology, the pre-printed paper label or plastic film label is placed in the mold, and the label is seamlessly fused to the thermoplastic material during the molding process, thus integrating the production and labeling process,

no need for post-labeling. After curing, the container and label will become a single waterproof and scratch-resistant piece. injection label inside an injection mold to decorate the plastic surface.At present, there are two manufacturing methods for IML.One is to make the printed Film Film into a circulating roller and roll belt, install it into injection molding machine and

injection mold, and produce the circulating belt in a fully automatic way, like Label affixed to the front die surface.This is called IML(transfer and injection in the mold). The Film is then printed, formed by Forming machines, then cut and placed in injection molds.This is called IML (injection molding with film in the mold).This film-general can be divided into three layers:

base material (usually PET), INK layer (INK),and adhesive material (usually a special adhesive). When the injection molding is finished, the Film and the plastic are tightly combined into the body through the adhesive effect. As the PET with the wear resistant protective Film on its positive surface is in the outermost layer, it has the effect of wear resistance and scratch

resistance. Its surface hardness can reach 3H, and the more it feels, the brighter it will be.Injection materials for PC, PMMA, PBT and so on.

Product Description

Our Advantages

1.It may improve efficiency, reduce the cost. Due to the combination of in mould label and plastic product forming happen at the same time ,it does not need to be separately labelled, so it may reduce the cost and energy consumption

2. It may improve the barrier property of products.As in mold label material usually is thin film , so it is waterproof, moistureproof, oilproof, mildewproof, acid and alkali resistant, friction resistant, low temperature resistance and can be soaked.

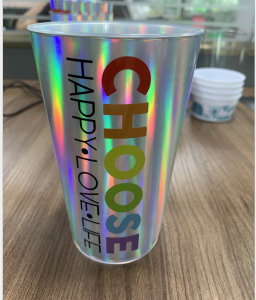

3,As its beautiful and high-definition printing quality, it is better than the traditional printing process effect.

4. In mold label is embeded into the product, becomes a part of product,so the label will not fall off, looks like no label effect, and has a certain security function.

5.It makes the recyling easier, environmental protection better.Becaue the material of product and in mold label are same or similar, so they can be melted and recycled at the same time, in this way in mold labe reduces the pollution to environment, and meets the standard of green printing.

6. increase the toughness of container mould process, at the same time, save the container resin dosage.

Material characteristics of pet heat transfer film:

①It has good mechanical properties, impact strength is 3~5 times that of other films, and good folding resistance.

②It is resistant to oil, fat, dilute acid, dilute alkali, and most solvents.

③It has excellent resistance to high and low temperatures. It can be used for a long time within a temperature range of 120°C, and can withstand high temperatures of 150°C and low temperatures of -70°C in short-term use, and has little effect on its mechanical properties at high and low temperatures.

④ The permeability of gas and water vapor is low, that is, it has excellent gas, water, oil and odor resistance.

⑤High transparency, can block ultraviolet rays and good gloss.

⑥Non-toxic, tasteless, good hygiene and safety, and can be directly used for food packaging. Because pet film has good stability, uniform tension, and minimal deviation of film thickness, it is most widely used.

1.Environmental protection printing,meet the requierment of international non-toxic standard.

2.Four color process printing design finish in one time,no need for the color register.

3.Simple transfer equipment with vivid printing effect.

4.Strong covering power and good adhesive.

5.High gloss,high image definition,toxic free In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of heat transfer printing film for plastic,pe plastic film, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Our company profile

Application Field

Application of pet heat transfer film Heat transfer film is suitable for hot stamping on the flat, curved, irregular,cylindrical, and conical surfaces of plastic, metal, leather, ceramics, wood and other products. It is widely used in daily necessities, cosmetics, stationery, toys, building materials, decorative materials, The surface printing and decoration of products in the industries of premium gifts, food packaging, signs, etc. and packaging. Such as the common plastic water cups in our lives, the beautiful heat transfer patterns on them are transferred on the heat transfer film of the water cup.

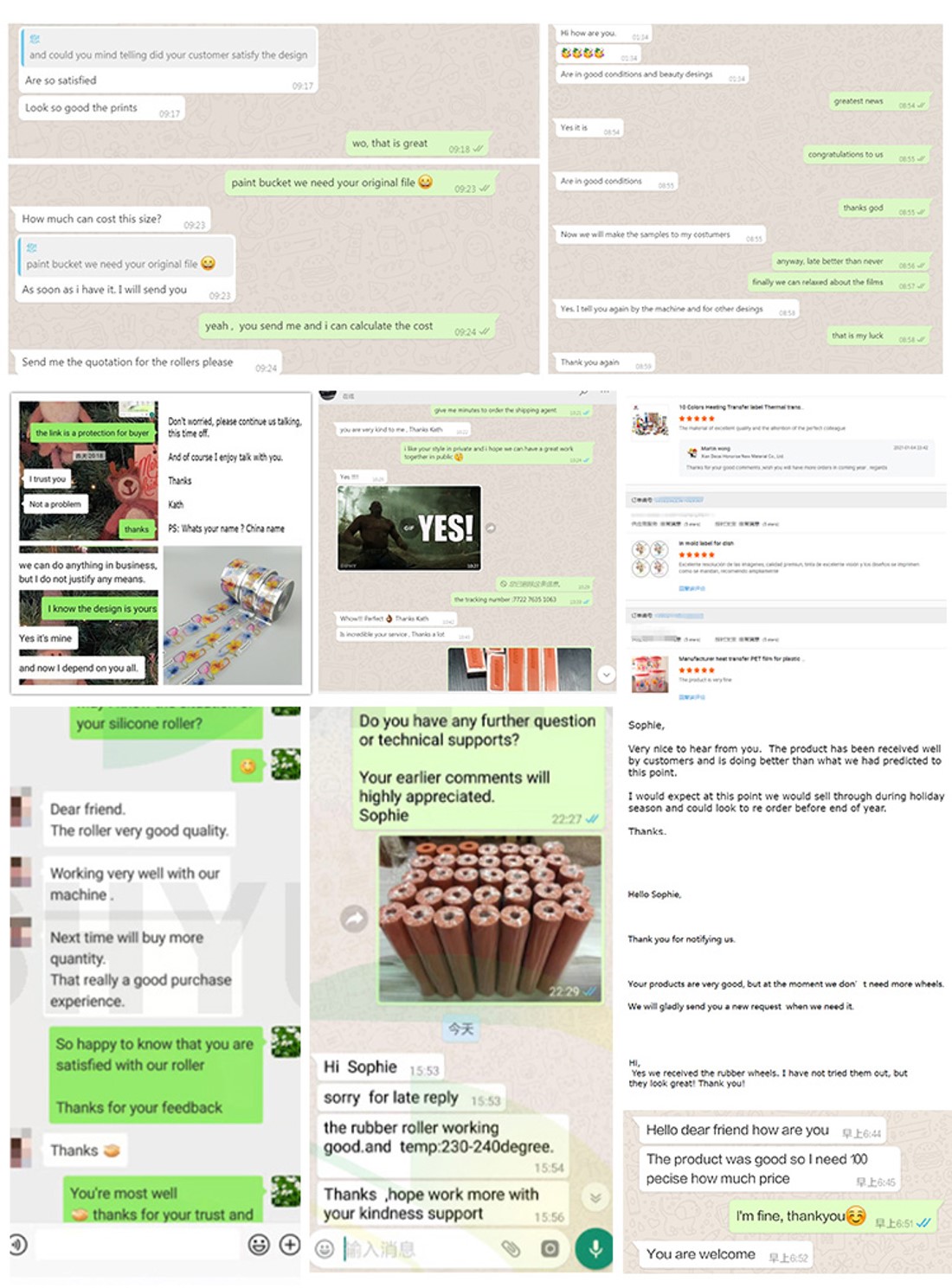

Feedback

FAQ

Q1: Are you a manufacturer?

Yes, we are a manufacturer supply in mold label and heat transfer film more than 20 years. If you want professional packing

solutions,please feel free to contact us.

Q2: This is the first time to buy the packaging, not sure how to start, what information I need to provide in order to get a price?

a. Application products

b. Size of the film

c. Design

d. Order quantity

Q3: Can I have sample first?

Yes of course, we will send you samples for testing before you make the order

4.Our six promises

1.We can do the designs according to the customer’s requirement

2.We can open customer’s own mould as per their requirement

3.We can offer you the high quality & reasonable price

4.We can offer you a good after-sell service

5.Promptly delivery

6.Free samples are available

Contact Us

WhatsApp

0086-17779025926

Wechat:

0086-17779025926

labelprint02_vip@126.com