IML in mold label for plastic cup bottle

Product description

IML, which stands for In-Mold Labeling, is a relatively new technology in the field of plastic cup manufacturing. It involves inserting a decorated label or graphic into the mold and then injecting the molten plastic material directly on top of it. The result is a plastic cup with a fully integrated label that is both durable and visually appealing.

IML has many advantages over other labeling methods for plastic cups. First and foremost, because the label is fused with the plastic material, it is virtually impossible to peel off or scratch. This makes IML cups ideal for use in various high-traffic environments such as restaurants, cafes, and outdoor events.

Moreover, IML cups offer excellent print quality and can be customized with vibrant, full-color graphics and logos. This makes them a popular choice for companies seeking to enhance their brand recognition and visibility. Additionally, IML cups can be produced in large quantities relatively quickly, helping to reduce lead time and improve production efficiency.

In summary, IML technology is a game-changer in the realm of plastic cup manufacturing. With its many benefits, including durability, visual appeal, and fast production times, it is no wonder that IML cups are becoming increasingly popular among businesses and consumers alike.

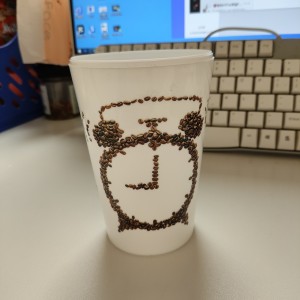

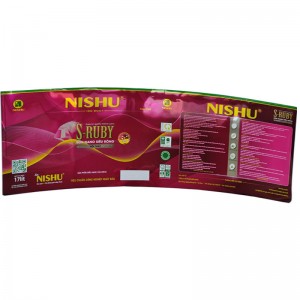

Product show

Description

| Product name | In mold label/sticker/film/foil |

| Material | OPP/BOPP |

| Surface | Glossy, Metallic, Orange, Matte |

| Size | As your requirement |

| Printing | Gravure printing, up to 10 colors |

| Thickness | 18-110 micron , as per customer's requirement |

| Shape | pieces, size according to the customer's requests |

| MOQ | 1000 sqm |

| Application | PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables etc |

| Packaging | PE bag + carton + packing belt + plastic pallet |

| Production time | cylinder making 5-7 days. label making 5-7 days |

| Payment terms | 50% advance payment, balance payment before delivery |

Production process

Company profile

Decai Honorise is a leading manufacturer of heating transfer field, one-stop service comprehensive enterprise. The products involves the following major aspects:High-precision hot stamping silicone rubber roller and wheel、gravure printing rubber roller and various industrial rubber rollers,Thermal transfer film labels and in-mold labeling,Heat transfer machine and hot stamping machine.Integrating production, sales and R&D together. In strict accordance with printing industry standards for production and management. We're own scientific formula, precise processing methods and superb grinding technology, we provide high-quality products with advanced production equipment and strong technical force.

Exhibition

Customer feedback