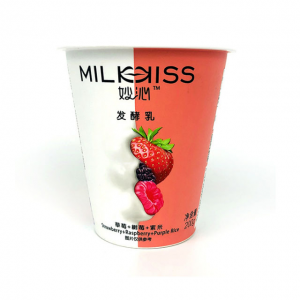

Injection mould IML label use for plastic cup in mold label

Short description

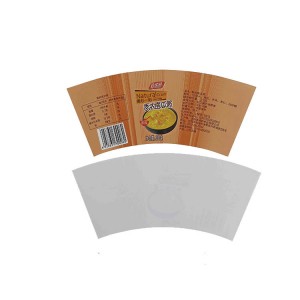

In Mold Paper is a new technique for placing Film Film inside an injection mold to decorate the plastic surface.At present, there are two manufacturing methods for IML. One is to make the printed Film Film into a circulating roller and roll belt, install it

into injection molding machine and injection mold, and produce the circulating belt in a fully automatic way, like Label affixed to the front die surface.This is called IML(transfer and injection in the mold).

The Film is then printed, formed by Forming machines, then cut and placed in injection molds.This is called IML (injection molding with film in the mold).This film-general can be divided into three layers: base material (usually PET), INK layer (INK),

and adhesive material (usually a special adhesive).

When the injection molding is finished, the Film and the plastic are tightly combined into the body through the adhesive effect.

As the PET with the wear resistant protective Film on its positive surface is in the outermost layer, it has the effect of wear

resistance and scratch resistance. Its surface hardness can reach 3H, and the more it feels, the brighter it will be.Injection

materials for PC, PMMA, PBT and so on.

Specification

| Product name | Injection mould IML label use for plastic cup in mold label |

| Size | As per customer's requirement |

| Material | BOPP/OPP |

| Surface & performance | Glossy, matte, orange peel etc. metallized silver & gold; scrub, laser, colored light etc. |

| Color | Accept customized |

| Printing | Gravure printing |

| Thickness | 18-110 micron , as per customer's requirement |

| Shape | in roll or pieces, size according to the customer's requests |

| Application | PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc |

| Packaging | PE bag + carton + packing belt + plastic pallet |

| Certification | SGS, FDA, ISO |

| Sample service | Acceptable |

| MOQ | 1000square meter (pcs depond on your product size ) |

| warranty | 1 year |

| production time | cylinder making 5-7 days. label making 5-7 days |

| Payment | T/T, Western Union, L/C, Ali accruance pay ;50% deposit and balance before shipment |

| shipment | By air/ Express or by Sea, up to clients |

| Our Advantages | 1..Free samples are available anytime when you need |

| 2.Free design 24 hours online help you | |

| 3.we have 13 sets printing machine and can offer you prompt delivery time. | |

| 4. import inks ,brighter color and perfect performance |

Production Process

- 1: Design

- 2: Making plate/cylinder<about need spend 7 days>

- 3: Prepare raw material

- 4: Prining<about 3 days>

- 5: lamination<3-5 working day>

- 6: Cutting<3-5 working days>

- 7: Cutting small sample and ship to customer test cutting size

- 8: QC

- 9: Packaging

- 10: Delivery

Packing and Shipping

Our company profile

Application Field

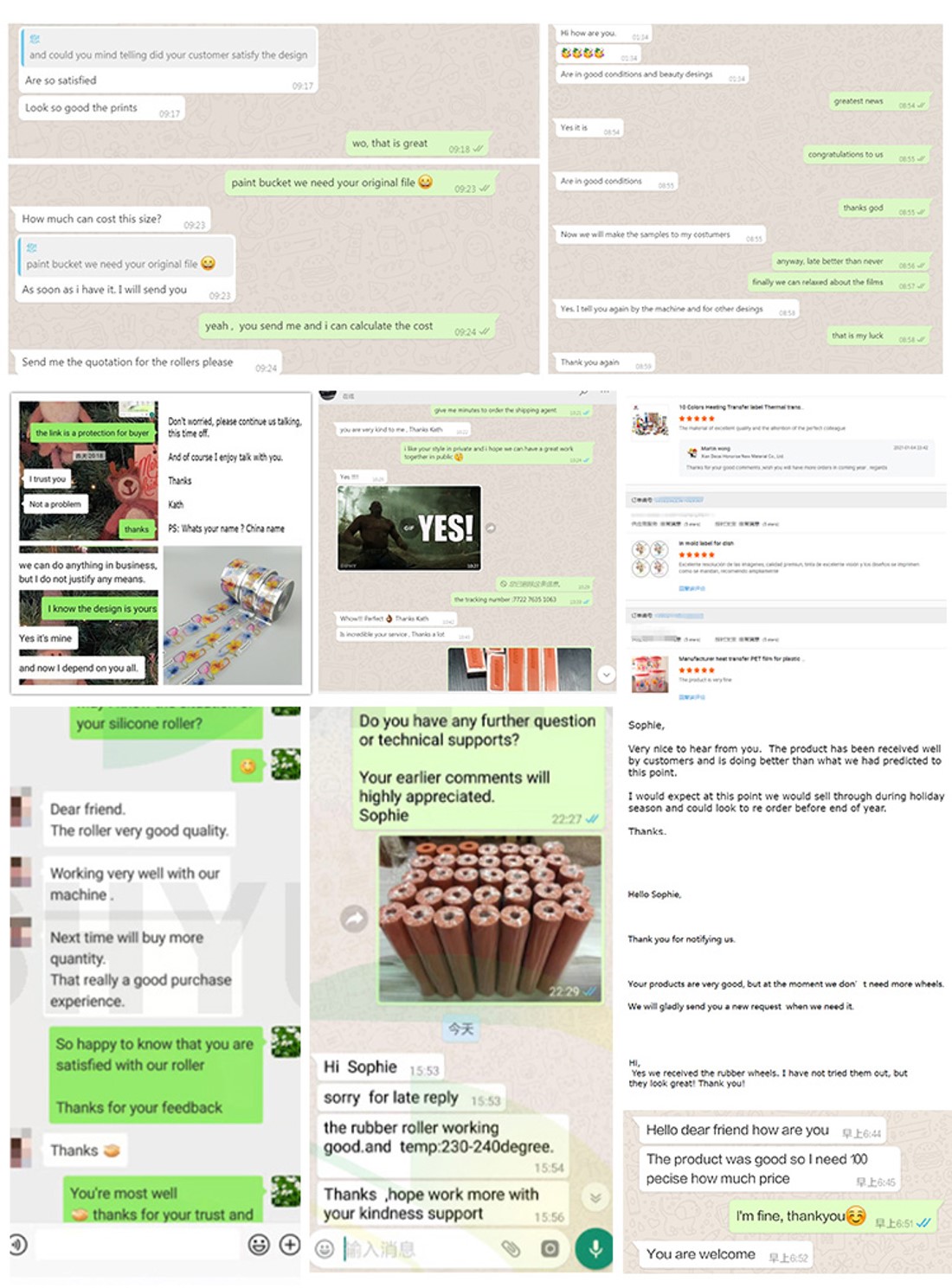

Feedback