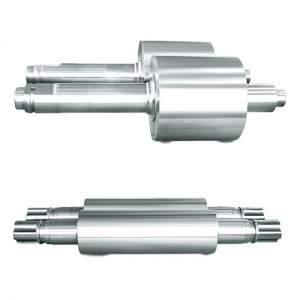

Measuring Tension Rolls steel Roller

The tension roller is to convert the torque acting on it by the driving device into the tension of the strip through the friction between the roller surface and the strip. The number and arrangement of the tension rollers depend on the maximum tensile force required by the strip and site conditions. . The tension roller group is generally divided into an inlet tension roller group and an outlet tension roller group, which can be driven by an electric motor or a hydraulic motor alone or can be interconnected through a gear differential device, but no matter how the driving device is different, its fundamental purpose is to cause The speed difference between the inlet belt and the outlet belt, thereby generating the tension required for driving.

|

Decai Steel Roller and Rolls Specification

|

|

|

Size

|

Any Size

According To Customer's Drawing,540*1510 is avaliable

|

|

Material

|

45# steel with plating,stainless steel

|

|

Hardness

|

50-70 degree

|

|

Tolerance

|

0.2mm

|

|

Types

|

Mirror roll, chrome plated, anilox roll |

|

Application Machine

|

industrial machine, printing machine and packaging machines and so on

|

|

Features of rubber roller |

1.Ozone and Chemical resistance

|

|

2.Anti-aging, good flexibility, good elasticity

|

|

|

3.Excellent oil resistance

|

|

|

4.Clean and healthy for many food and medical applications

|

|