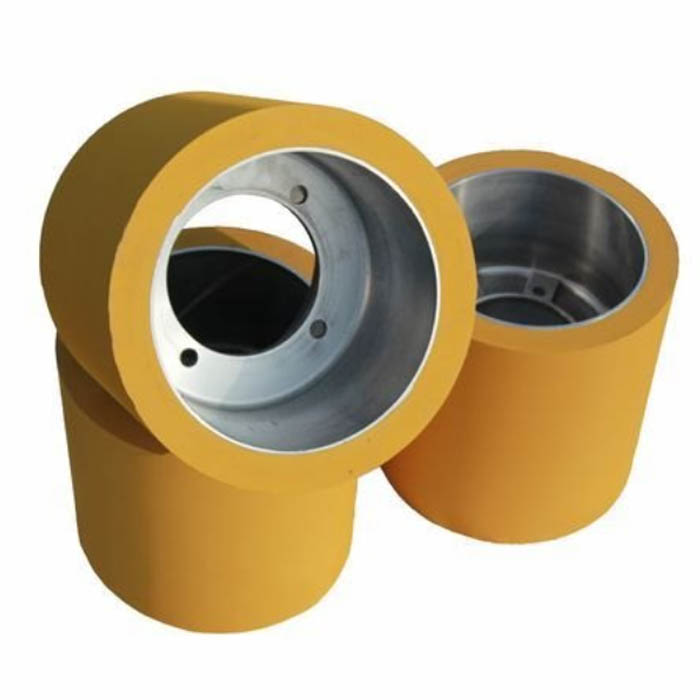

The basic performance of the hulling rubber roller (the amount of grain) depends on the physical and mechanical properties of the external rubber, and the performance is as follows ;

(1) Tensile strength: Strength refers to the ability of a material to resist damage caused by external force. Strength refers to the ratio of the relay force when the rubber test piece is stretched to break and the cross-sectional area of the initial test piece. The unit is MPa ( kg/Cm2). For the rubber roller, this is an important mechanical property. The rubber roller has to follow the action of a variety of external forces during the rice milling process and perform high-speed and violent mechanical movement. Therefore, the rubber must have a high strength, otherwise it will Reduce the use value of rubber rollers.

(2) Elasticity: It is one of the most important properties of rubber materials. It refers to the ability of the rubber to deform under the action of an external force and return to its original state after the external force is removed. There are many indicators for measuring elasticity, such as: constant stress elongation, elongation, permanent deformation at break and heat generation. For the hulling rubber roller, moderate elasticity is required. Although high elasticity can improve the shelling ability, reduce the bursting of the waist, and less broken rice, but the elasticity is too high, it is easy to produce large elastic deformation, increase the heat generation, increase the working temperature of the rubber roller, and reduce other mechanical and physical properties of the rubber. . For example, the hardness will decrease and it cannot be used. The elasticity is too low, the hardness is too high, the wear resistance is poor, and it is easy to cause damage.

(3) Hardness: Hardness refers to the ability of rubber to resist deformation when compressed and invaded by external forces. Generally, Shore A hardness tester is used to measure its value. Generally speaking, the hardness requirements of rubber rollers are relatively strict. Too high will increase the glue consumption of the rubber roller and too low of broken rice will reduce the hulling rate. Grain hulling rubber rollers should be equipped with different hardness values according to different regions, seasons and other conditions of use (such as rice type, temperature, etc.). Generally, the hardness of rubber rollers are 85 degrees, 90 degrees, and 95 degrees. The tolerance ranges are within ±3 degrees. It must be pointed out that the above hardness is not a fixed value. Depending on the production season, its value is at the standard temperature (23℃±2o). ) And measured under the standard sample, and the hardness value of the rubber roller in actual work is different from the rated value of the rubber roller, and it will generally be lowered.

(4) Anti-aging performance: The so-called aging refers to the deterioration of the quality of rubber due to the physical and chemical effects of oxygen, odor, heat, and light beams in the air during long-term storage and use of rubber. The physical and mechanical properties of the husked rubber roller are degraded and scrapped. After the aging of the husked rubber rollers, they become hard, brittle, cracked, and moldy. The elastic strength of the rubber material is greatly reduced, which seriously affects the use effect, even though the rubber rollers are in production. Many anti-aging measures have been taken at the time, but it is still very important to do a good job in anti-aging work.

(5) Balance: Balance refers to the ability of the rubber roller to maintain a fixed axis of rotation when it rotates. Strictly speaking, it is a dynamic balance. However, because the rubber roller is not a precision mechanical part, and the dynamic balance is not easy to measure, it is actually The concept of static balance is adopted, that is, the symmetry of the quality of each part in the warp direction with respect to the working axis, commonly known as "heaviness". The balance of the rubber roller has an impact on the hulling rate, the brown rice rate, the glue consumption and the normal operation of the rice hulling machine. Have a major impact.

Post time: Jun-24-2021