FREE SHIPPING ON ALL BUSHNELL PRODUCTS

News

-

Heat Transfer Film

Heat transfer printing utilizes high-quality gravure printed on a clear carrier that are permanently bonded to a part by the heat and pressure of the heat transfer process. Since heat transfer label are preprinted, multi color images are transferred to the part in one pa...Read more -

In mold label application

In-mold labeling is mainly used for blow molding and injection molding products of PP, PE, PET and other materials. That is, before blowing and injection molding, put the printed in-mold paste into the blowing and injection molding cavity. When the mold is closed for blo...Read more -

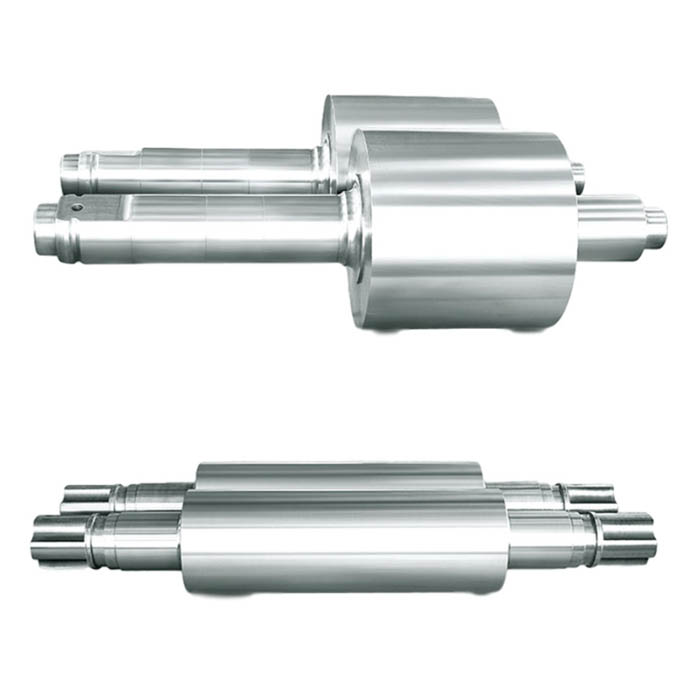

Development direction of Hot Strip and Cold Mill Rolling Work roll

The cold roll is a complex component with a very hard surface layer, which bears a lot of stress. Therefore, the cold roll requires high manufacturing quality, which is a necessary condition to ensure the effect of use. The development of cold rolli...Read more -

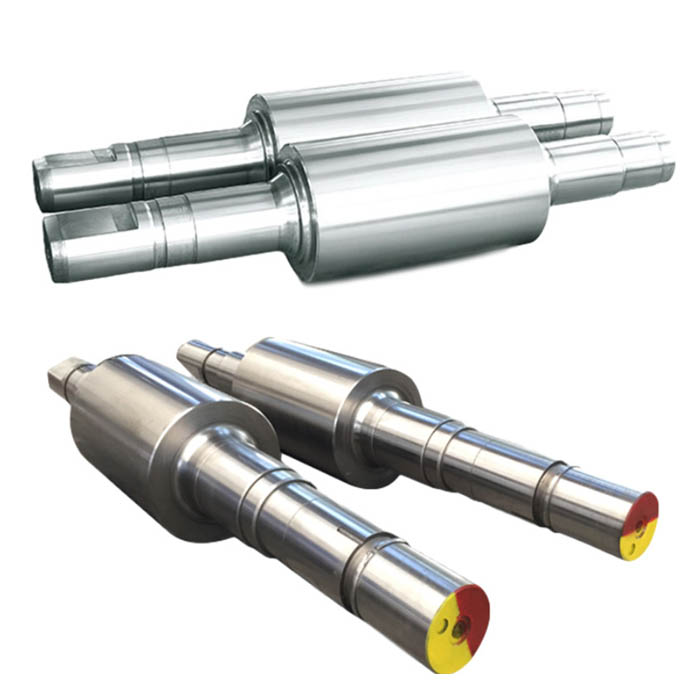

rolling machine hot rolling steel roller Texturing Technology

Cold rolling mill roll: Rolls used for cold rolling are generally flat rolls for rolling sheets and strips. Cold rolls in a broad sense include work rolls that are in contact with the rolling stock and backup rolls that support them. Because backup rolls are self-contain...Read more -

Four steps to solve the hot stamping defect of heat transfer film

1. Keep the machine clean: keep the important parts of the machine clean, free from oil and dust, keep the thermal transfer film clean, free from fingerprints and dust, keep the printing products clean, free from dust and oil, and keep the hands of the processor clean , ...Read more -

Use of cold rolls cold rolling mill roller

The service life of cold rolls not only depends on the manufacturing quality, but also is closely related to the maintenance during use. If it is used improperly, the use effect will change greatly. Fatigue spalling is the most common failure form i...Read more -

What is the price of rubber rollers?

The price of rubber rollers is about one or two hundred yuan each, the cheap ones are ten or twenty yuan, and the expensive ones are several hundred yuan. The price of rubber rollers is affected by many aspects, such as brand, category, specification, market, etc. The ke...Read more -

In mold label is mainly used in these industries

1. Oil industry , including lubricating oil, gear oil, antifreeze products packaging. 2. Daily chemical product industry, such as shower gel, shampoo, cleaner, detergent and personal care products packaging 3. The food industry: soy sauce, ice cream, coffee, juice, tea d...Read more -

Return Roller Market – Application Analysis, Business Opportunities, Regional Outlook to 2028

This brings some changes and this report also covers the impact of COVID-19 on the global market. The Rolling Wheel Market Analysis Summary by Reports Insights is a thorough study of the current trends leading to this vertical trend across various regions.Furthermore, this study emphasizes a comp...Read more -

Rubber market size forecast to be valued at USD 51.21 billion

PUNE, Sept. 23, 2020 (GLOBE NEWSWIRE) — The global rubber market size is expected to reach USD 51.21 billion by 2027, growing at a CAGR of 5.3% during the forecast period.In a report titled “Rubber Market Size, Share and COVID-19 Impact Analysis” by Fortune Business Insights, in...Read more -

The process of rubber coated processing?

In general, the rubber roller coating process means that the customer provides the rubber roller iron core. The rubber roller factory is responsible for rubberizing and grinding the rubber roller iron core, and grinding the rubber roller into the required size, color, ha...Read more -

What is the heat transfer film composed of?

What is the heat transfer film composed of? 1. Base layer: the carrier of the release layer, printing layer and adhesive layer - thermal transfer base film, thermal transfer base film includes pet film, opp film, pvc film, etc., which need to be selected according to the...Read more