FREE SHIPPING ON ALL BUSHNELL PRODUCTS

News

-

What are the properties of rubber rollers that can be used better

(1) Wetting It is mainly the affinity of the rubber roller to ink (the ink roller must have good lipophilic and water-resistant properties so that the ink can spread well on the surface of the ink roller. This is the basic condition for the uniform ink layer; the water...Read more -

Introduction to the characteristics and applications of various rubber rollers

Rubber Roller: Excellent oil resistance, good wear resistance, aging resistance, and heat resistance. They are used in printing, printing, dyeing, chemical fiber, paper, packaging, plastic processing and other equipment and other occasions where they are exposed to oil a...Read more -

The process of heat transfer film production

Product Description The process of heat transfer film prodction Heat transfer printing is divided into heat transfer plate making and heat transfer film printing and thermal ...Read more -

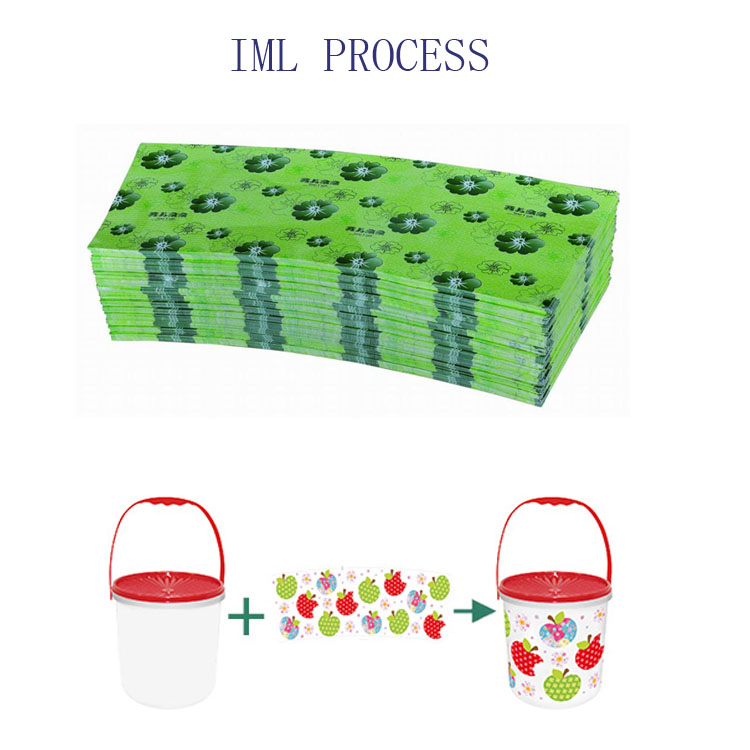

What is IML process?

What is IML process? In-mould labelling (IML process) is the innovative labelling technology for plastic packaging. The procedure is sophisticated: pre-printed labels are placed in the injection moulding machine. This means that the labelling process takes place during ...Read more -

Repair methods and skills of printing rubber rollers

In the work project, the printing rubber rollers usually appear, wear, and break holes. If a new roller is replaced, the cost is too high and the production schedule will be affected. It can be repaired with rubber repair agent. Mending process, taking the BD916 rubber m...Read more -

Application scope of rubber rollers and types

1. Ethylene-propylene rubber roller: Excellent ozone aging resistance, weather resistance, wide operating temperature, long-term work at -65℃-140℃, excellent insulation performance, used in plastic printing machinery, tanning machinery, and general fields. 2. Polyurethan...Read more -

The main purpose of printing machine rubber roller

The rubber roller of the printing press mainly transfers ink on the offset press. Therefore, the rubber roller must be carefully cleaned during daily cleaning, otherwise the surface layer of the rubber roller and the pigment and resin will be oxidized to form a smooth an...Read more -

The feature of the heat transfer film

The heat transfer feature is that the printed pattern is clear, and the secondary printing is highly reductive, so the theat transfer has a unique flaw in the curved surface and the flat surface, because the heat transfer is capable of...Read more -

Troubles and troubleshooting in the operation of the hulling rubber roller on the machine

General faults and troubleshooting methods in the operation of the hulling rubber roller on the machine The method of removing the cause of the fault (1)The rubber roller is stuck 1. If the blanking is uneven, adjust whether the accelerating plate is smooth and whet...Read more -

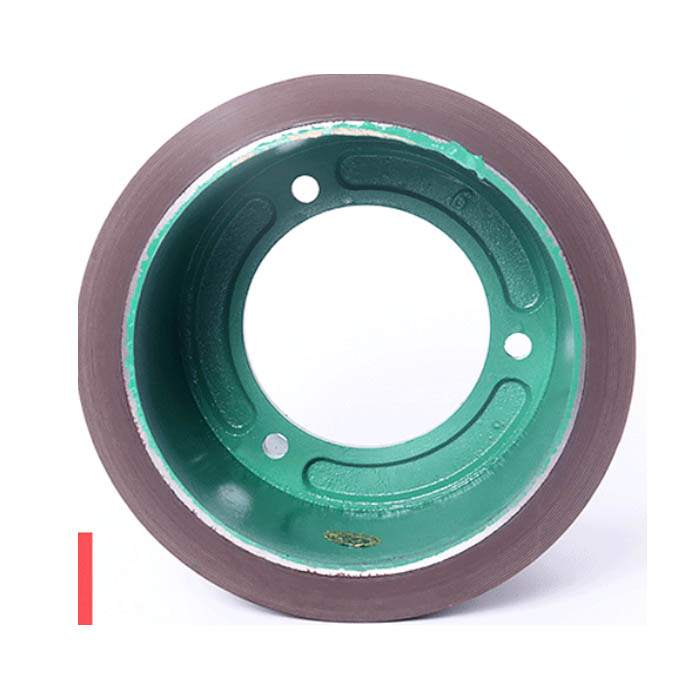

Introduction and comparison of different rubber material for rice Hulling Rubber Roller

The first generation of rice Hulling Rubber rubber roller (SBR for short) Rubber roller, low price, less broken rice, poor wear resistance The second generation of rice Hulling polyurethane rubber roller (Pu) plastic roller, wear-resistant, suitable for use in cold regio...Read more -

basic performance of rice hulling rubber roller

The basic performance of the hulling rubber roller (the amount of grain) depends on the physical and mechanical properties of the external rubber, and the performance is as follows ; (1) Tensile strength: Strength refers to the ability of a material to resist damage caus...Read more -

What are the main characteristics of the printing rubber roller?

What are the main features of the rubber roller of the printing machine ? 1. The rubber roller of the printing machine has surface viscosity. Therefore, the rubber roller has good ink transfer and inking performance in the printing process, and good ink affinity can have...Read more