FREE SHIPPING ON ALL BUSHNELL PRODUCTS

News

-

The Advantage of IML

The benefit of In Mold Label 1. Strong design group for all kinds of design and pattern; 2. All raw material prepared inspection before production; 3. Printing Ink: Made DIC by Japan manufacture; 4. Glue: Strong adhesive by South Korea Supplier; 5. All the p...Read more -

What are the repair methods for printing rubber rollers?

What are the repair methods for printing rubber rollers? There are several maintenance methods: 1. The rubber rollers should be cleaned carefully after the production operation is completed every day, and washed twice; 2. Designated chemical agents, such as industrial alcohol, must be us...Read more -

About In mold label for milk tea cup products:

About In mold label for milk tea cup products: In-mold labeling is a new label packaging form that is different from the traditional direct screen printing, heat shrinkable labels, and self-adhesive labels. It has been popular in Europe and the United States ...Read more -

The main purpose of food grade silicone tube

Food-grade silicone tube is made of imported silicone raw materials, scientific production technology, and batch method for raw rubber production, aiming at the high tear resistance and high transparency of fumed rubber, the ultra-high and lower hardness of the rubber co...Read more -

What is the in mold labeling?Blow Mold or Injection Mold?

In-Mold Labeling In-mold labeling (IML) describes a fully automated process in which the pre-printed IML film label is placed in the mold before the container is created. The label seamlessly fuses to the hot plastic material as its being molded, combining the production...Read more -

Silicone cake mold maintenance method

1. Please clean the silicone mold in time after each use. 2. Do not rinse with cold water immediately after leaving the oven to prolong the service life. 3. Wash with hot water and diluted edible detergent, or wash in the dishwasher. 4. Do not use corrosive detergent or ...Read more -

Precautions for the use of silicone cake molds

1. For the second use, please clean the silicone cake mold and apply a layer of butter on the mold. This operation can extend the life of the mold. There is no need to repeat this operation afterwards. 2. Do not directly touch open flames or heat sources, and do not appr...Read more -

How to use silicone cake mold ?

1. Stir the cake making ingredients according to the cake making recipe, and put them in the silicone cake mold. 2. Put the raw materials according to the shape of the silicone cake mold and shape the cake. 3. Sprinkle decorations such as chocolate and raisins on top of ...Read more -

Silicone products supplier

DECAI silicone products manufacturers have many years of experience in the production of silicone products, and have a R&D and production technical team to conduct R&D and production of silicone products to ensure product quality and meet export certification sta...Read more -

How to use silicone rubber roller?

1. Turn on the heating to check whether the silicone roller rotates normally, turn it off and pay attention to whether the residual temperature delay is normal. The residual temperature delay is generally set at 40-50 minutes. 2. When replacing the rubber roller to tighten the silicone, wai...Read more -

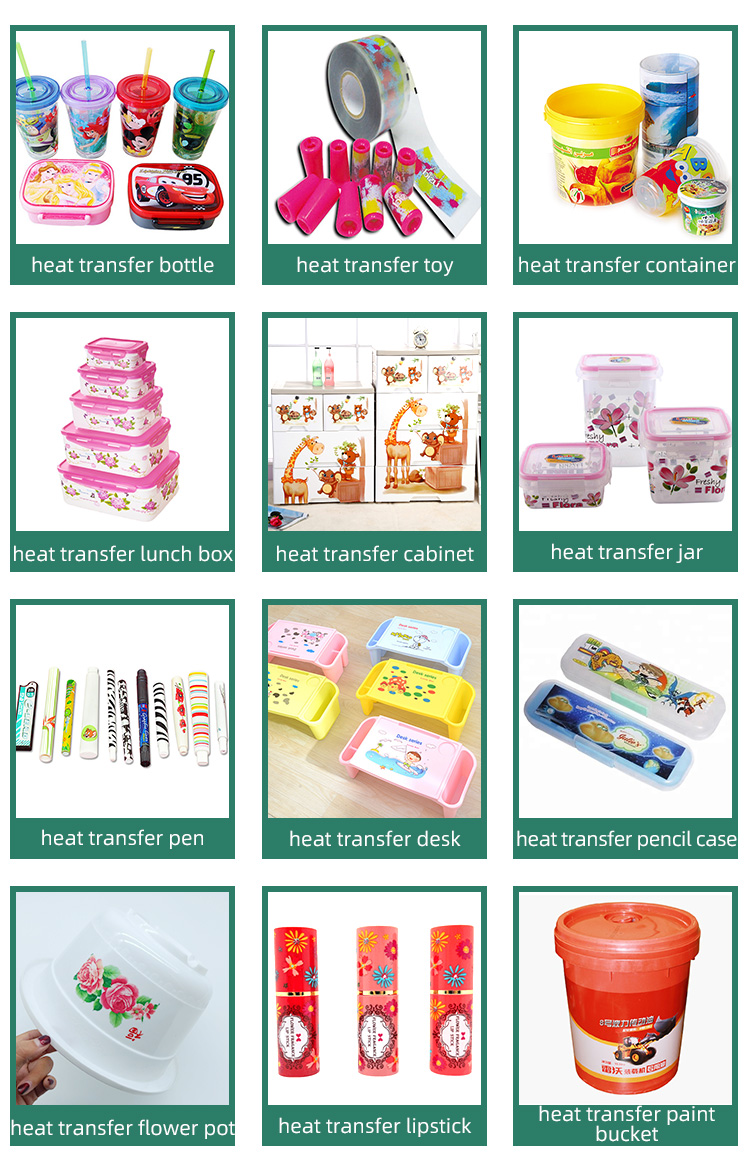

The advantages of the heat transfer film

The advantages of the heat transfer film are: 1: Green environmental protection seal, no pollution, in line with international standards. 2: Eight-color patterns are printed at one time, without color registration, which avoids the sho...Read more -

What are the characteristics of polyurethane rubber roller?

(1) Polyurethane rubber rollers have good chemical properties and are suitable for various types of inks and printing methods. It has special resistance to solvent components in various inks, fountain solutions and cleaning agents. (2) The colloid used for polyurethane rubber rollers has s...Read more