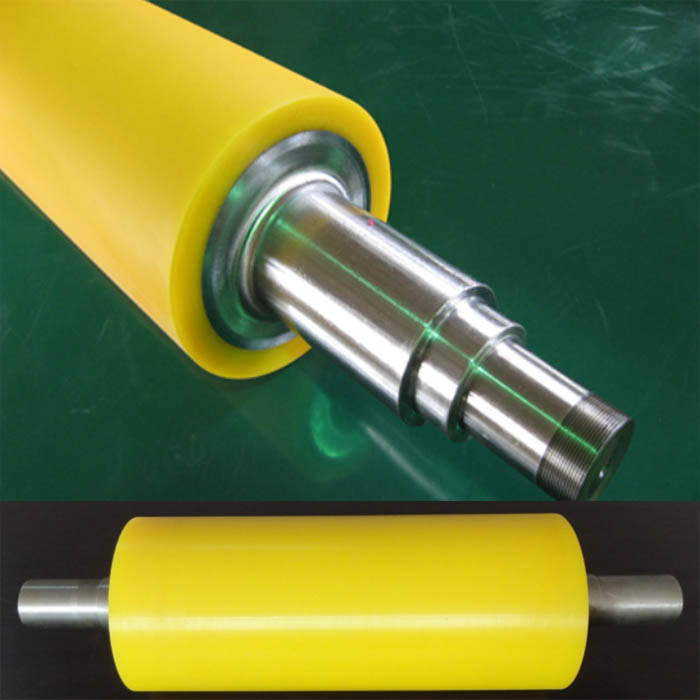

Polyurethane conveying rollers, DECAI polyurethane products have excellent acid resistance, alkali resistance and solvent resistance; excellent wear resistance, ozone resistance; outstanding compression resistance, high resilience, and high bearing capacity.

Regarding the reasons for the degumming of polyurethane rubber rollers, the development of modernization, polyurethane rubber rollers are used in various industries, and polyurethane rubber rollers are an important component of load-bearing transportation, which are important in various industries. The application requirements are very strict to analyze the reasons for the degumming of polyurethane rubber rollers in application. :

1. The reason for the degumming of the polyurethane rubber roller and the temperature of the core: During the process of casting polyurethane, the temperature of the core and the core is similar to the temperature of the polyurethane raw material. When the temperature difference between the two materials is large, the curing speed of the materials is not uniform, resulting in a large internal stress of the polyurethane material after curing.

2. Mold requirements: The design and manufacture of molds require good sealing, and the closure is easy to open and release. The reasons for the degumming of the polyurethane rubber roller, the design of the mold, and the thermal balance of the polyurethane are an important factor. Uneven heated rolls during curing at high temperatures occur when the interface between the polyurethane core and the polyurethane cured is incomplete, low elastic strength, or cracks appear.

3. The selection of the adhesive needs to be based on the bonding theory. The molecular force can be formed between the polymer material with large molecular and the surface of the metal material, and there is no tight bond between the material and the metal.

4. The selected adhesion According to the theory, the large molecules between the surface of the polymer material and the metal material can be formed by intermolecular forces, forming the metal material tightly.

5. The reasons for the degumming of polyurethane pads for polyurethane rubber rollers Polyurethane formula: manufacturers should adjust the formula according to different working conditions, such as load-bearing, rotating speed and by using the network environment, so that it can be more suitable for the working conditions described by customers.

6. Iron core surface treatment: Iron core treatment Cast iron roll core treatment is also one of the keys to the rubber roller. To produce a good combination of polyurethane elastomer and iron core, the iron core needs to be cleaned, pickled, derusted, decontaminated, etc. to make its surface clean. Mechanical blasting is usually one of the methods of bond strength.

Polyurethane is an elastomer, a strong polar polymer compound, has almost no affinity with non-polar mineral oil, and is hardly corroded in fuel and engine oil. Aging resistance, superior performance, good anti-oxidation and ozone properties are indeed a good material.

Post time: Jan-26-2022