PET film printer for paint buckets heat transfer film for plastic

PET film printer for paint buckets heat transfer film for plastic

Heat transfer film for plastic is a specialized material used to print high-quality designs on paint buckets and other plastic containers. The process involves printing the desired pattern onto a PET film using a PET film printer for paint buckets, then transferring it onto the plastic surface using heat and pressure. This method ensures durability, vibrant colors, and resistance to fading or peeling. The heat transfer film for plastic is compatible with various substrates, including HDPE and PP, making it ideal for industrial and decorative applications. It offers excellent adhesion, scratch resistance, and waterproof properties. Advanced films also support metallic, glossy, or matte finishes. Using a PET film printer for paint buckets ensures precise, high-resolution prints, while the heat transfer process guarantees long-lasting results. This technology is widely used in packaging, branding, and promotional items, providing a cost-effective and efficient solution for plastic bucket decoration.

Product description

Key benefits include:

1)Customizable designs for branding, logos, and product information.

2)Strong adhesion to PP/HDPE plastic, ensuring durability.

3)Eco-friendly and efficient for mass production. This method is widely used for printing plastic paint buckets, offering a cost-effective and professional finish.

| Product name | Heat transfer film label |

| Film material | PET |

| Size | According to your design drawings |

| Application product | plastic products(such as PP,PE,PC,PS,PET,ABS etc) |

| Surface | Glossy film |

| Film printing type | Gravure printing |

| Thickness | 20μm |

| Shape | in roll |

| Length | 400m/roll |

| Width | Max 120cm |

| Feature | Bright colors |

| Packaging | Plastic film + carton+plastic pallet |

| Payment terms | 50% advance payment,balance payment before delivery |

Product show

1) Your product color is too dark, and the white base of the thermal transfer film is not thick, resulting in the product color showing through after printing. You can use 2 or even 3 layers of white on the design artwork.

2)Thicken and deepen the white ink,or use high-concentration white.

Q:How to ensure that the colors of design drawings are more standard?

1) For the electronic draft, the customer confirms the color and size. If there is a 5% difference between the product and the design draft, the customer will be informed in advance.

2) Use Pantone color cards to compare color numbers with customers.

Production process

Production Steps of Heat Transfer Film:

1. Plate Making (Engraving/Printing Plate Preparation)

- A custom printing plate (gravure or flexographic) is created based on the design file to ensure precise pattern transfer.

2. Printing (Multi-Layer Coating & Color Application)

- The base film (PET/PP) is coated with release and adhesive layers, then printed with the desired pattern using solvent-based or UV inks.

3. Drying (Curing & Solvent Evaporation)

- Printed films pass through a drying tunnel to evaporate solvents and solidify inks, ensuring color fastness and adhesion.

4. Slitting (Precision Cutting to Width)

- Dried films are cut into specific widths using slitting machines to meet customer roll size requirements.

5. Quality Inspection & Packaging

- Each roll undergoes checks for color accuracy, adhesion, and defects before being packed for shipment.

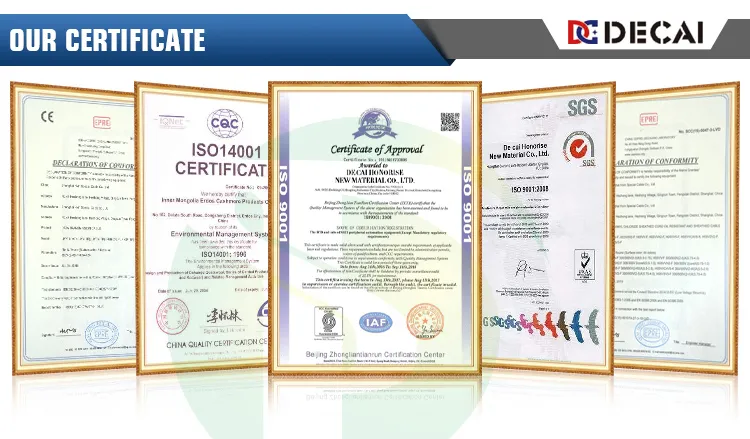

Company profile

Decai Honorise is a leading manufacturer of heating transfer field, one-stop service comprehensive enterprise. The products involves the following major aspects:High-precision hot stamping silicone rubber roller and wheel、gravure printing rubber roller and various industrial rubber rollers,Thermal transfer film labels and in-mold labeling,Heat transfer machine and hot stamping machine.Integrating production, sales and R&D together. In strict accordance with printing industry standards for production and management. We're own scientific formula, precise processing methods and superb grinding technology, we provide high-quality products with advanced production equipment and strong technical force.

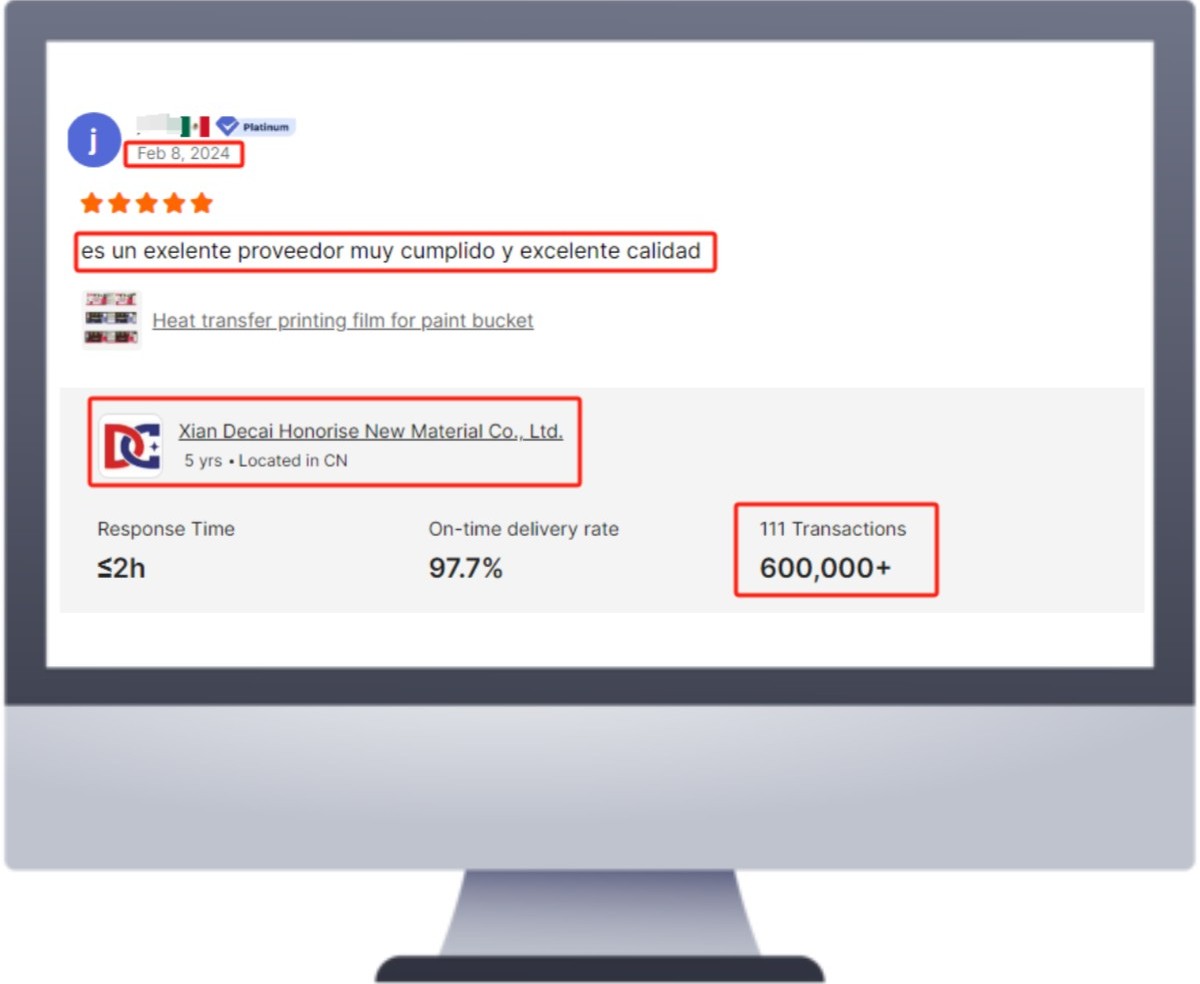

Exhibition&Feedback

Packaging&Shipping

FAQ

1.Are you a manufacturer?

2.Can you provide samples?

Yes, we can provide you samples for quality checking. Please let us know your requirements, then we can arrange samples according to your requirements. Our samples are free, but the delivery charge is on your side.

3.How can we guarantee quality?

Always a pre-production sample before mass production;Always final Inspection before shipment.

4.What is "heat transfer printing' ?

Heat transfer film uses PET raw materials and prints customized artwork on the PET raw materials through gravure printing technology. After the customer receives the heat transfer film, the pattern on the PET raw material is transferred to the surface of the product using the high-temperature printing of the heat transfer machine, thus forming a decorative effect.

5.How to use heat transfer printing ?

1)firstly you must have a heat transfer printing machine, we also produce this machine

3) your product should have smooth surface(flat or round conical shape)

6.This is the first time to buy, what information I need to provide in order to get a price?

1)Material of your product

2)Size of the film /your product

3)do you have own orginal design? We support AI,PSD,CDR or PDF format.

4) Order quantity

5)If possiable pls send sample product to us

7.How can we contact you as soon as possible?

We are always available on Alibaba.com, WhatsApp, Wechat. You can also reach us by email. You are welcome to send us any questions anytime and we will reply you.

Related products

Metallized heat transfer film

Heat transfer machine