PET material heat transfer film stickers for plastic house ware

Product description

Heat transfer film for plastic product packaging is an innovative solution that allows for high-quality, durable packaging that is both visually appealing and functional. The film is designed to be applied to plastic products using heat, which allows for the design or image to transfer seamlessly onto the packaging. This process results in a lower cost and a reduction in waste compared to traditional packaging methods.

Heat transfer film can be used for a wide range of plastic products such as bottles, containers, and jars. It is an ideal choice for brands looking to stand out from their competitors on store shelves. The film offers a high-quality finish, with vibrant colors and intricate designs that are sure to catch the eye of consumers.

In addition to its aesthetic benefits, heat transfer film also provides functional advantages. The film is highly resistant to scratches and abrasions, ensuring that the product remains intact during transportation and storage. It is also resistant to water and chemicals, which makes it a reliable choice for packaging products that need to be protected from moisture or chemical exposure.

One of the significant advantages of heat transfer film is its sustainability. The film can be produced with eco-friendly materials, reducing the environmental impact of the packaging. Additionally, it generates less waste than traditional packaging methods since the film can be applied precisely to the product, eliminating the need for excess packaging material.

Overall, heat transfer film is a cutting-edge solution for plastic product packaging. Its ability to combine high-quality visuals, durability, and sustainability makes it a popular choice among brands. By choosing heat transfer film, companies can create packaging designs that are not only visually appealing but also cost-effective, functional, and environmentally friendly.

Product show

Production process

| How to order heat transfer film/label? | |

| Artwork | we will make a layout for you according to your design and size |

| Confirm the artwork | You confirm the layout,we will launch your order for plate making |

| Plate making | It take about 4-7 days |

| Print the film | Print in big rolls - drying - cut into small rolls /piece- quality check.It take about 5-7 days(glitter film needs 5 days more for aluminized) |

| Packing | hardboard+ tape+Neutral box + wooden case |

| Delivery | According to your requirements |

Company profile

Decai Honorise is a leading manufacturer of heating transfer field, one-stop service comprehensive enterprise. The products involves the following major aspects:High-precision hot stamping silicone rubber roller and wheel、gravure printing rubber roller and various industrial rubber rollers,Thermal transfer film labels and in-mold labeling,Heat transfer machine and hot stamping machine.Integrating production, sales and R&D together. In strict accordance with printing industry standards for production and management. We're own scientific formula, precise processing methods and superb grinding technology, we provide high-quality products with advanced production equipment and strong technical force.

Certification&Feedback

FAQ

1.Are you a manufacturer?

2.Can you provide samples?

Yes, we can provide you samples for quality checking. Please let us know your requirements, then we can arrange samples according to your requirements. Our samples are free, but the delivery charge is on your side.3.How can we guarantee quality?

Always a pre-production sample before mass production;Always final Inspection before shipment.

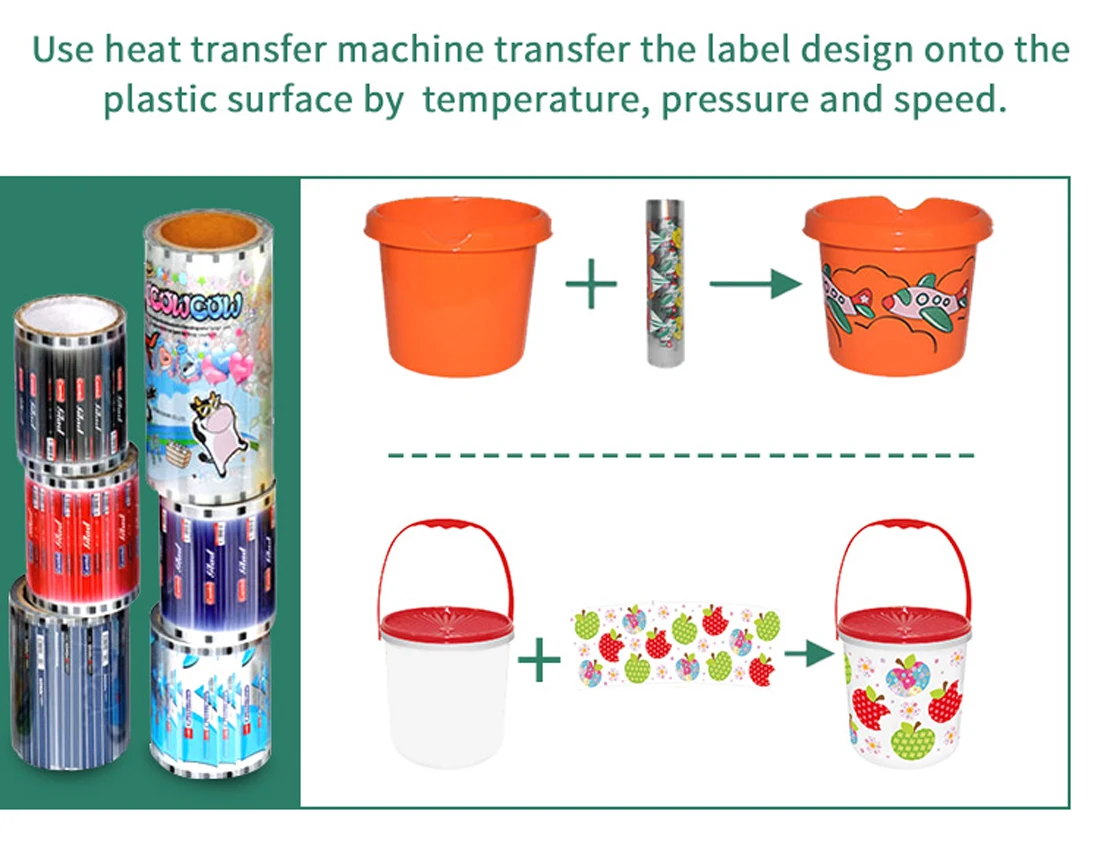

4.What is "heat transfer printing' ?

Heat transfer printing utilizes high-quality gravure printed on a clear carrier that are permanently bonded to a part by the heat and pressure of the heat transfer process. Since heat transfer label are preprinted, multicolor images are transferred to the part in one pass.

5.How to use heat transfer printing ?

1)firstly you must have a heat transfer printing machine, we also produce this machine

3) your product should have smooth surface(flat or round conical shape)

6.This is the first time to buy, what information I need to provide in order to get a price?

1)Material of your product

2)Size of the film /your product

3)do you have own orginal design?

4) Order quantity

5)If possiable pls send sample product to us7.How can we contact you as soon as possible?

We are always available on Alibaba.com, WhatsApp, Wechat. You can also reach us by email. You are welcome to send us any questions anytime and we will reply you.