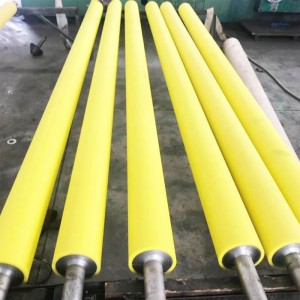

printing rubber roller industrial rubber rollers printing roller of vulcanised rubber

DECAI is a professional manufacturer of various printing rubber rollers, color steel rubber rollers, leather machine rubber rollers, glass mechanical rubber rollers, laminating rubber rollers, Shimu mechanical rubber rollers

The purpose of our factory is: to be a real person, to make friends with sincerity, and to seek development with quality. General manager Qiao Jianzhong greets new and old customers!

Your support is your trust in us, we will return your support with good quality and ultra-low price!

The application of polyurethane rubber rollers began in the early 1980s, and thereafter market demand has increased. The spare parts of polyurethane rubber rollers in the equipment introduced in the papermaking, steel, printing and dyeing, textile and other industries are in urgent need of localization, such as the cold rolling production line, which accounts for 1/3 of the total number of rubber rollers, and the amount is quite objective. In technological transformation and technological innovation, it is urgently needed to replace ordinary rubber rollers to increase production efficiency and save energy consumption. For example, the cost of removing 1kg of water from the drying part of a paper machine is about 10 times higher than that of the pressing part. The roller surface material is made of polyurethane rubber instead of natural rubber, and the linear pressure it bears can be increased by 2 to 3 times, which increases the dehydration rate of the paper.