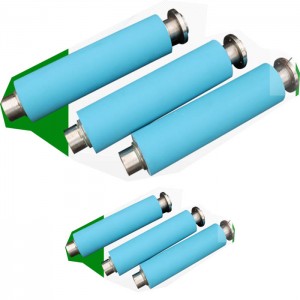

Printing silicone Rubber Roller with aluminum core

In the offset printing technology, the key is the control of the balance between water and ink channels, and the balance of ink and water relies on the key components of rubber rollers and ink rollers, whose quality can directly affect product quality. This is especially true for gravure, embossing, and flexo printing. General printing companies have to maintain equipment once a week, including the maintenance of printing rubber rollers.

|

Decai Rubber Roller Specification

|

|

|

Size

|

Dia:10MM-670MM;

Length:50MM-8200MM

According To Customer's Drawing

|

|

Material

|

NBR,Silicone,Rubber,Polyurethane,NR,PU FFPM,ETC,EPDM

|

|

Hardness

|

18A-100D

|

|

Tolerance

|

0.05mm

|

|

Color

|

yellow,Black, orange,green or custome required

|

|

Core Material

|

stainless steel,45#steel or aluminum

|

|

Application Machine

|

industrial machine, printing machine and packaging machines and so on

|

|

Features of rubber roller |

1.Ozone and Chemical resistance

|

|

2.Anti-aging, good flexibility, good elasticity

|

|

|

3.Excellent oil resistance

|

|

|

4.Clean and healthy for many food and medical applications

|

|

Detailed material description of our rubber rollers

We are using #45 steel , #201stainless steel #304stainless steel and 5# aluminum seamless pipe as the base roller.And we are adopting a reasonable thickness base roller according to customer’s drawing.Some manufacturers will reduce the thickness of the steel pipe in order to get the price advantage.Such roller can’t meet the standards.But we won’t do that.

Our rubber are all imported from Germany or the US and then we mix them in our factory.The rubber coating technical we are using is winding technical. we cast the rubber on the base roller layer by layer and then vulcanize it to make the green rubber into mature rubber.While other manufacturers are using sheet coating technical,and the rubber is cold in processing and will cause adhesion problems easily.

Characteristics of rubber roller :

A. NBR rubber roller

NBR rubber roller can be used as printing roller, food industry rubber roller, dyeing roller in textile printing in dustry and the soft rubber roller for contacting solvent and so on.

Note: The NBR has poor ozone resistance and the operation should be avoided in a high concentration ozone environment during processing.

B. Neoprene roller

Suitable for the soft printing roller, gravure printing roller and so on.

C. Silicone roller

High temperature resistance which can reach 200-250 degrees, and good chemical resistance,but it has low tensile strength.Silicone roller can be used in fabric heat setting, plastic heat setting embossing, calendering, photocopying and so on.

D. Polyurethane rubber

It has outstanding tensile strength wear resistance and crack resistance and good resistance to a variety of solvents.