-

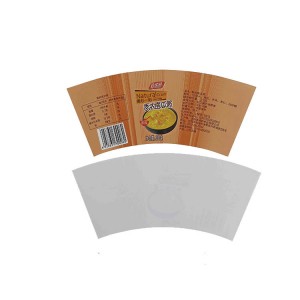

Plastic jar In mold foil glossy IML in mold label for plastic jar

IML container vs Ordinary container, who is the winner? Specification Product name Plastic jar In mold foil glossy IML in mold label for plastic jar Size Accept custom Material Eco-Friendly PP. Printing Gravure printing Application PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc Packaging PE bag + carton + packing belt + plastic pallet Certification SGS, FDA, ISO Sample service Acceptable MOQ 1000SQ.M (Can be negotiated ) warranty ... -

Custom mold in graphics label pp cup in mold labeling

What’s the IML in mold label? Feature *.Fine picture, can be completed with an ordinary ironing machine, heat transfer machine. *.Color pattern forming one time, no need for Color registration. *.Simple operation, fine printing, low production cost. *.Widely used on Shoes, housewares, Stationery, Cosmetics etc *.According to the green printing standards, no environmental pollution. *.Strong adhesion and wear resistance after transfer printing, also can increase product va... -

Injection in mold label for plastic product

Advantage Specification Product name Injection in mold label for plastic product Size Accept custom Material Eco-Friendly PP. Surface & performance Glossy Color Up to 10 colors Printing Gravure printing Thickness 75 micron Shape in roll or pieces, size according to the customer’s requests Application PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc Packaging PE bag + carton + packing belt + plastic pallet Certification S... -

IML PP labels in mould label for plastic ice cream box

Advantage Specification Product name IML PP labels in mould label for plastic ice cream box Size Accept custom Material Eco-Friendly PP. Surface & performance Glossy Color Up to 10 colors Printing Gravure printing Thickness 75 micron Shape in roll or pieces, size according to the customer’s requests Application PP/ PS/ PE Plastic Products, such as plates, cups, bowls, chairs, tables, etc Packaging PE bag + carton + packing belt + plastic pallet Cert... -

IML Static Generation Equipment In mold labeling Static Charging Equipment

The electrostatic generator mainly generates static electricity. The output is usually single polarity, such as positive or negative polarity, and the output voltage can be adjusted. -

In mold foil charger static charger 20KV

In-mould decorating is a process for labeling or decorating a plastic object during the plastic injection molding process. In the in-mold labeling process, a label or appliqué is placed in the open mold and held in the desired position by vacuum ports, electrostatic attraction or other appropriate means. The mold closes and molten plastic resin is extruded or injected into the mold where it conforms to the shape of the object -

In mold foil charger static charger Equipment

These machines are suitable for thin foil charging in injection molding and blow molding machine i.e. portable applications in domestic as well as industrial use. -

static charge generator electrostatic charge

electrostatic charge is programmable for either voltage or current control mode to supply the high voltage for charging bars and various charging applicators used to electrostatically bond materials. The DECAI provides a robust solution for a wide range of production processes maximizing the efficiency of the application. -

NEW upgrade IML Static Charging Generator

Applications

In mould labelling (IML).

Static charges can be used to pin a decorative label tight against the inner mould surface during injection moulding without the use of vacuum. This procedure greatly improves finished product quality. Outside the mould a robot presents the label to a charging bar which applies an electrostatic charge to the label. The label is then placed into the mould cavity, where it sticks due to the electrostatic bond between the label and the metal mould wall. The label will not slip or change position in the mould. -

Factory Price Heat Transfer Machine

Heat transfer printing machine widely used in stationary, cosmetics, toys, household daily necessities, and other industry products and packaging materials on a printed decoration, and it is a decoration printing machine, which must have implemented heat , pressure, and a transfer speed. Its high production efficiency, significant economic benefits, is a kind of ideal equipment for surface processing industry. -

Low Price Heat Transfer Printing Machine for Plastic

Heat transfer machines can be divided according to the types of machines. Divided into: heat transfer machine, flat ironing machine, high pressure heat transfer machine, shaking head heat transfer machine, The printing range is very wide, including flat heat transfers, but also curved heat transfers such as cups, plates. -

Muanfacture Heat Transfer Printing Machine

Heat transfer printing machine is a decoration printing machine, which must have implemented heat , pressure, and a transfer speed. It is suitable for hot stamping foil production. Its high production efficiency, significant economic benefits, is a kind of ideal equipment for surface processing industry.

FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Decai's bronzing, heat transfer silica gel roller and wheel, hot stamping silicone rubber plate(pad)are widely used in stationery, electrical appliances, toys, cosmetics boxes, cigarette packets, wine box wood, stainless steel, glass, paper, leather, soft and hard plastic printing packaging field.