-

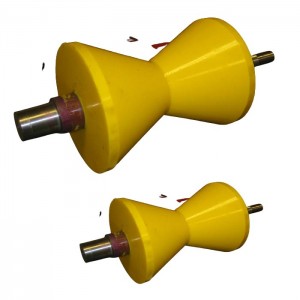

Urethane pipeline V rollers Industrial rubber roller

To have the highest quality of resurfaced V-rollers, DECAI's plan to resurface old worn V-rollers is the ideal solution for companies in pipeline and related industries. The process is to remove the old urethane or rubber, blast the steel hub, then recast the hub with polyurethane. -

PU Coated rubber roller CONE TYPE pipe rollers

Pipe rollers is our main rubber products and we have a professional engineers team to meet all determine parameter for PU coated pipe roller. -

Nylon cone type pipe roller

Pipeline rollers are designed to protect, support, and guide a pipeline section during river and road crossings. -

Pipe PU Guide Rollers polyurethane Rubber roller supplier in China

We offer these products at reasonable rates and deliver Pipe PU Guide Rollers within the promised time-frame,we have gained a huge clientele of polyurethane Rubber roller across the nation. -

Pipeline Crossing PU Rollers polyurethane Rubber roller maker

We are a leading Manufacturer of a wide range of Pipeline Crossing PU Rollers, polyurethane Rubber roller in China. -

Pipe Pulling PU Rollers polyurethane Rubber roller factory

Backed by years of industry experience, we are engaged in offering a premium quality range of Pipe Pulling PU Rollers polyurethane Rubber roller -

V shape PU rubber roller Antistatic Polyurethane wheels

Supplying V shape PU rubber roller Antistatic Polyurethane wheels. Our polyurethane wheel is antistatic, hydrolysis-resistant, and abrasion-resistant, with a special quality test report. -

Heavy Duty Pipe Roller used for Oil and Gas pipeline equipment

Motivated to attain maximum client satisfaction, we offer the best quality of Heavy Duty Pipe Roller. -

industrial pipe rollers PU polyurethane rubber roller

DECAI offers wide range of industrial pipe rollers . PU polyurethane rubber roller is used in oil and gas pipeline installation where pipe in racks and modules, space is limited and crane cannot access -

Polyurethane V Roller for oil and gas pipeline

We are supplying heavy duty polyurethane pipe roller is for used for hanging natural gas pipelines and electric lines -

Pipeline polyurethane rubber Roller Pipe PU Roller

DECAI is leading manufacturer and supplier of pipe rubber rollers. DECAI Pipe pu Rollers are manufactured to be simple to use and handle. -

High Performance Polyurethanes roller wheel for Conveyor Applications

If you are looking for High Performance Polyurethanes For Heavy Duty Conveyor Applications,welcome you contact us.

FREE SHIPPING ON ALL BUSHNELL PRODUCTS

Decai's bronzing, heat transfer silica gel roller and wheel, hot stamping silicone rubber plate(pad)are widely used in stationery, electrical appliances, toys, cosmetics boxes, cigarette packets, wine box wood, stainless steel, glass, paper, leather, soft and hard plastic printing packaging field.