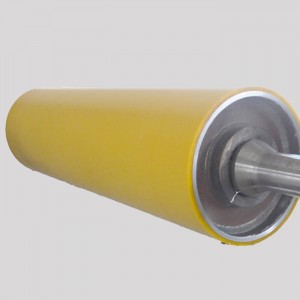

PU Polyurethane Glass cleaning rubber roller

Glass cleaning rubber roller, using polyurethane material, polyurethane rubber roller, has excellent high-strength compression and wear resistance, oil resistance, solvent resistance, corrosion resistance, a wide range of hardness, and strong adhesion to metal without degumming. It is widely used in metallurgical papermaking coal.

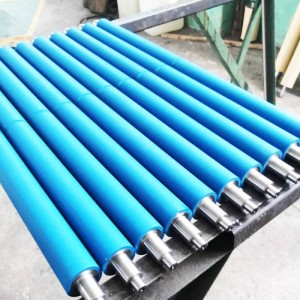

Specializing in the production of various rubber rollers,such as NBR rubber roller,Neoprene rubber roller,Silicone rubber roller,Polyurethane rubber roller and so on.

The company's products are widely used in printing, metallurgy, aluminum, wood, leather, paper, electronic, Conveying equipment, printing and dyeing, textile and other industries..

Decai Rubber Roller Characteristic

- Wearable

- Oil resistant

- Solvent resistant

- preservative

Characteristics of rubber roller :

A. NBR rubber roller

NBR rubber roller can be used as printing roller, food industry rubber roller, dyeing roller in textile printing in dustry and the soft rubber roller for contacting solvent and so on.

Note: The NBR has poor ozone resistance and the operation should be avoided in a high concentration ozone environment during processing.

B. Neoprene roller

Suitable for the soft printing roller, gravure printing roller and so on.

C. Silicone roller

High temperature resistance which can reach 200-250 degrees, and good chemical resistance,but it has low tensile strength.Silicone roller can be used in fabric heat setting, plastic heat setting embossing, calendering, photocopying and so on.

D. Polyurethane rubber

It has outstanding tensile strength wear resistance and crack resistance and good resistance to a variety of solvents.

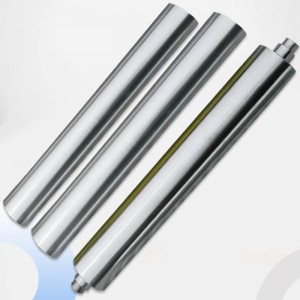

E. Mirror roller

We generally adopt 45 # steel, alloy steel seamless pipe, precision forgings as the material.The surface of the roller finish degree can reach RA0.01. Mirror processing can ensure the roller surface flatness, balance, non-roundness, coaxial degree meet the customers’requirements.