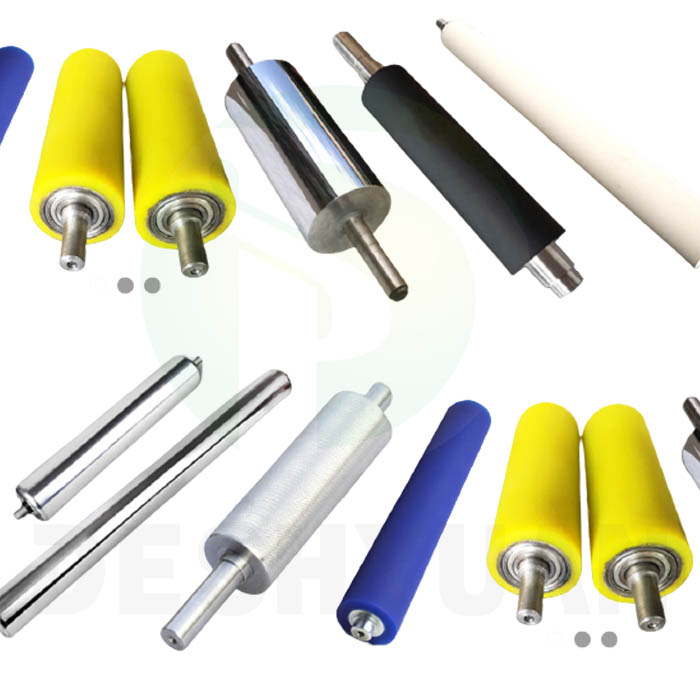

Rubber roller manufacturer polyurethane PU rollers supplying

There are several ways to maintain the printing rubber roller:

1. The rubber roller should be cleaned carefully after the production operation is completed every day, and washed twice;

2. Designated chemical agents, such as industrial alcohol, must be used to clean the printing rubber roller, and corrosive

solvents must not be used;

3. Take off the rubber roller during holidays to prevent deformation under pressure;

4. For the protection of the surface of the printing rubber roller, it should be wrapped in newsprint and placed in a ventilated and dark place.

Characteristics of rubber roller :

A. NBR rubber roller

NBR rubber roller can be used as printing roller, food industry rubber roller, dyeing roller in textile printing in dustry and the soft rubber roller for contacting solvent and so on.

Note: The NBR has poor ozone resistance and the operation should be avoided in a high concentration ozone environment during processing.

B. Neoprene roller

Suitable for the soft printing roller, gravure printing roller and so on.

C. Silicone roller

High temperature resistance which can reach 200-250 degrees, and good chemical resistance,but it has low tensile strength.Silicone roller can be used in fabric heat setting, plastic heat setting embossing, calendering, photocopying and so on.

D. Polyurethane rubber

It has outstanding tensile strength wear resistance and crack resistance and good resistance to a variety of solvents.

E. Mirror roller

We generally adopt 45 # steel, alloy steel seamless pipe, precision forgings as the material.The surface of the roller finish degree can reach RA0.01. Mirror processing can ensure the roller surface flatness, balance, non-roundness, coaxial degree meet the customers’requirements.