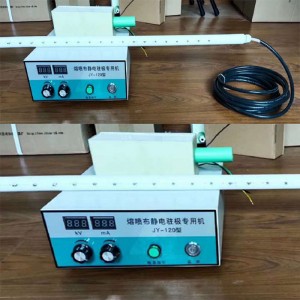

static charger for Non-Woven Fabric machines 220V 60HZ 120KV

static charger for Non-Woven Fabric machines 220V 60HZ 120KV.

Electrostatic generator, in line with standard standards. Electrostatic generator, can be produced according to your requirements, welcome to call for detailed inquiries,-factory direct supply, ESD-20H meets the requirements of IEC and GB/T standards.

Electrostatic electret machine is also called electrostatic generator, suitable for mask meltblown cloth, cloth batch flocking, etc. This machine can operate at high power frequency for 24 hours, strong electrostatic field, stable output, oil-immersed insulation cooling, and adopts imported core electronics The components and transformers are completely self-developed and produced, with many years of experience in the production of high-voltage equipment, providing strong quality guarantee, strong production capacity and short delivery time, which can meet the order requirements of various customers. Welcome to order!

Product Features:

1. Use of melt blown cloth electrostatic generator. DC high voltage generator has small ripple coefficient, stable and reliable voltage output, no noise, and good reliability.

2. With over-voltage, over-current, zero-voltage start and fault protection functions, the voltage protection value can be set, and the display is intuitive

3. The voltage and current adopt digital display, and the power can be read, which is convenient to monitor the output status

4. With 0.75 times voltage conversion, it is convenient to test zinc oxide arrester

5. The product has a compact structure, small size and convenient carrying

Product Introduction:

High-frequency voltage doubler circuit, advanced PWM high-frequency pulse width modulation technology, closed-loop adjustment, and large voltage feedback are used to greatly improve the voltage stability. Use high-power IGBT devices and drive technology with superior performance, and adopt special shielding, isolation and grounding measures according to the electromagnetic compatibility theory. The DC high voltage generator realizes high quality, portable, and can withstand the rated voltage discharge without damage. It has the characteristics of large output power and small size, and has reliable overvoltage, overcurrent and zero closing protection functions, with 0.75 times voltage switching function.

It is mainly used for DC withstand voltage test or DC leakage current test of high voltage electrical equipment such as zinc oxide arresters, power cables, transformers, circuit breakers, generators, etc. in power departments, industrial and mining, metallurgy, steel and other enterprises.

Operating Steps:

(1) Input power detection and voltage regulator return to zero.

(2) Connect the three-phase power line and the neutral line to the corresponding terminal on the back of the test bench, and the test transformer reliably grounds the ground bolt of the test bench cabinet;

(3) Close the external power switch;

(4) Turn the "master control power switch" to the "on" position. At this time, the red light of the "power indication" switch cabinet power-on test bench, all meters and the "green light of the button with light" are on.

(5) Turn the "three-phase four-wire power supply voltage conversion switch" to "CA", "BC", and "AB" to display the corresponding line voltage (380V).

(6) The zero return operation of the regulator:

Whether it can produce the 95 standard ?

It is not the size of the machine, it mainly depends on the strict use of materials and strict production technology.

In addition to the different raw materials for the production of qualified and standard meltblown cloth, the difference lies in the machine. The die head, melting temperature, wind speed, electrostatic electret and other parameters of the meltblown cloth machine are all different.

In addition to the machine, if you have a super professional tuning master. The following is the experience sharing of the first-line adjustment masters from the meltblown cloth factory for many years!

1. Small machines are generally defined by the screw diameter, and large machines are defined by the width (width) of the cloth, which is the effective width of the spinneret.

2. The soil machine has no pressure sensor, no non-stop screen changer, the material pressure is too large, the screw friction heats up, and the actual melt material temperature far exceeds the set temperature, and the cloth will be brittle.

3. The heating system of the small machine is controlled by the AC contactor, the heating plate is full power output and stop, the temperature of the heating plate is actually very high, the barrel wall of the screw is thin, and the material close to the barrel wall It's actually overheated. But the temperature of the material inside is not enough. So it appears that the set temperature is not high, but the cloth that comes out is relatively brittle.

4. The sorrow of the small machine, the material is too good, and the liquidity is too good. When the hot air is large, the melt is not drawn into silk, but is directly blown off, forming small liquid beads and hitting the cloth.

5. The small machine needs to use materials with a lower melting point because when the small machine uses materials with a high melting point, because the material flow rate is too fast, the small machine's thermal compensation, wind compensation, and air pressure compensation are too late to keep up.

5. The craftsmanship of the soil gun machine is unstable, the machine is unstable, and the accessories can be used as soon as possible, and they are uneven.

Also have other model static generator for IML