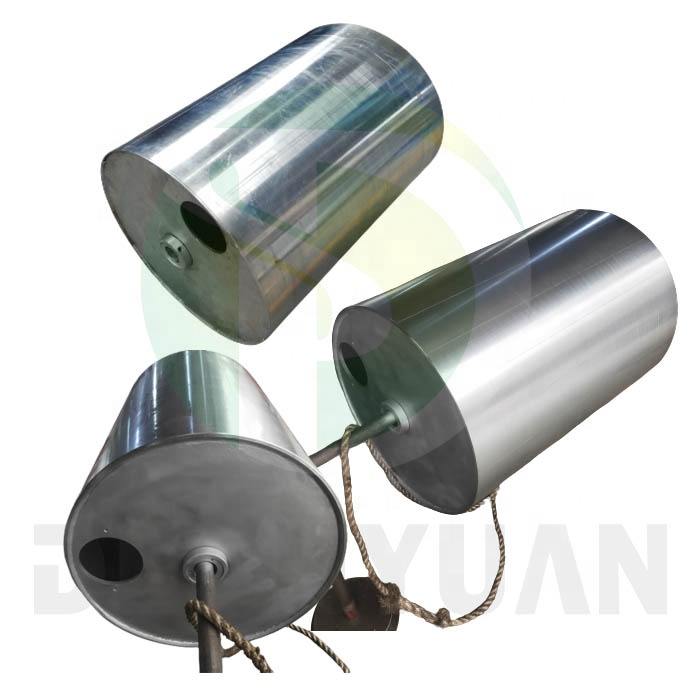

steel conveyor roller Industrial big stainless steel idler rollsls

We are only powerful factories in China that can produce this big steel rollers rolls

Steel roller roll process steps:

1. Cutting: use seamless steel tube for roller body, 45 round steel for shaft, Q235 steel plate for end plate, cut material with

8mm machining allowance according to drawing size.

2. Turning processing: Turning the joint surface of the mating parts of the roller body, end plate and shaft, etc., according to the H9/f9 matching accuracy.

3. Weld the reinforcement ribs and shafts at both ends of the combined roller body, pay attention to correct the coaxiality of the shafts at both ends and the inner sleeve, and only weld the inner end plate on the shaft.

4. Put the complete inner sleeve of the combined welding into the roller body, and the mating junction of the inner end plate of the combined welding and the roller body.

5. Install the outer end plate on the shaft at both ends, and weld the junction of the outer end plate and the joint surface of

the shaft and the roller body.

6. Anneal the welded roll blanks to eliminate internal stress.

7. One end of the steel roller is flattened and a standard center hole is drilled.

8. Turning processing: Divide rough and fine turning steel roller body parts to the size required by the drawings. The working surface roughness of the roll body should not be greater than 1.6μm; the working surface of the roll has a radial runout tolerance of 0.025mm on the shaft support surfaces (rolling bearing installation parts) at both ends; the roundness of the working surface of the roll body is 0.036mm; bearing coordination The circle is processed with k6 precision. Then set the center frame, the end face of the car, and drill to size.

9. Process the pattern according to the pattern requirements of the pattern steel roller. Then a hard chrome layer is plated with a thickness of 0.03~0. 05mm.

10 Correct the static balance of the steel roller.

|

Decai Steel Roller and Rolls Specification

|

|

|

Size

|

Any Size

According To Customer's Drawing

|

|

Material

|

45# steel with plating,stainless steel

|

|

Hardness

|

50-70 degree

|

|

Tolerance

|

0.2mm

|

|

Types

|

Mirror roll, chrome plated, anilox roll |

|

Application Machine

|

industrial machine, printing machine and packaging machines and so on

|

|

Features of rubber roller |

1.Ozone and Chemical resistance

|

|

2.Anti-aging, good flexibility, good elasticity

|

|

|

3.Excellent oil resistance

|

|

|

4.Clean and healthy for many food and medical applications

|

|