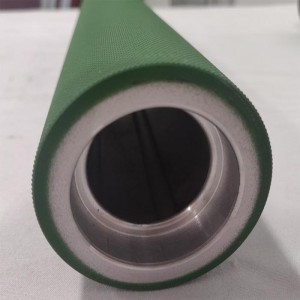

Teflon aluminum guide roller

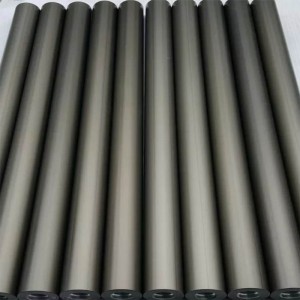

The aluminum guide roller is made of high-quality aluminum alloy material, and is molded into a tube shape with a rib structure inside, which has good scratch resistance, wear resistance and anti-sticking properties. The outer diameter has various specifications such as Φ22m-Φ320mm. All shafts are calibrated by computer dynamic balance, so that the highest accuracy of balance can reach within 5g. Using sophisticated equipment and special tools, the gloss of the roller surface can reach 0.8 or 0.4 and the coaxiality can reach 0.02mm. The shaft end is treated with a special process and matched with imported bearings, so it can operate easily at high speeds. It is suitable for printing, packaging, plastics, papermaking, glass fiber, pharmaceuticals, electronic batteries, textiles and other machinery industries and various coil processing industries.

Aluminum guide rollers have high strength, low resistance, light weight, flexible rotation, no rust, wear resistance and corrosion resistance. They are especially suitable for printing, packaging, plastics, electronic batteries and other precision machinery industries and various coil processing industries.

The aluminum guide roller is made of high-quality aluminum material and is made by good processing technology; DECAI is engaged in the manufacture and sales of paper, film, film, textile, rubber and other thin film rolls related to the roll control system peripheral equipment, such as air shaft , Inflatable shaft/safety chuck, edge tracker (side-aligning machine) device, aluminum guide roller, magnetic powder brake and clutch, rewinding and unwinding linkage system, tension control device and other related printing, lamination, slitting, Rewinding, coating, gluing, extrusion, laminating and other industrial machinery parts, etc.

|

Decai Aluminum guide roller Specification

|

|

|

Size

|

Any Size

According To Customer's Drawing

|

|

Material

|

Aluminum |

|

Diamter

|

22-320mm |

|

Length

|

100-6000mm |

|

Anodize

|

HV300/HV700 |

|

Thickness of anodize

|

20-80μm |

|

Type

|

Without shaft/ With shaft/ Through shaft |

|

Surface

|

Smooth/ Cross line/ Center line/ Groove line |

| Smoothness | Ra6.3-0.4 |

| Balancing | G6.3/G2.5 |

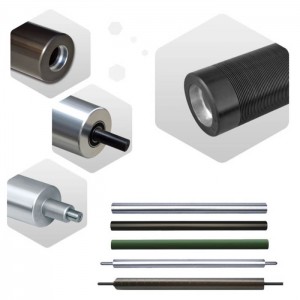

What are the structural classifications of aluminum guide rollers?

The structure of aluminum roller can be roughly divided into:

(1) Hollow aluminum roller: Inner bearing type structure, the bearings are assembled in the bearing holes on both ends.

(2) Coupling aluminum roller: The two ends of the roller body are combined with steel shaft or stainless steel shaft end, which is a one-piece structure.

(3) Water-passing aluminum roller: cooling or heating liquid enters and exits through both sides and circulates in the roller body.