Top rank sales heat transfer pet film pet heat transfer film transfer film for plastic cup

Top rank sales heat transfer pet film pet heat transfer film transfer film for plastic cup The working principle of the heat transfer stickers is to use the heat transfer process to transfer the pattern on the application product, which is resistant to high temperature, does not deform, does not degummed, and is not easy to fade. In addition to the advantages of characteristics, the product is also very convenient to operate, not only easy to engrave, but also the scrap rate is low .It used to all kinds of plastic as ABS, AS, PS, PC, PP ,PET ,PVC , glass, stainless steel,and other products.

Widely applied in household,furniture, office stationery, electrical products, building decoration materials, cosmetics packaging,etc .

Product Description

Our Advantages

1.Strong design group for all kinds of design and pattern;

2. All raw material prepared inspection before production;

3.Printing Ink : Made DIC by Japan manufacture;

4.Glue : Strong adhesive by South Korea supplier;

5.All the printing color are measured and checked by Al and Computerized;

6.23 years production and Q,C experience for label printing process .

Material characteristics of pet heat transfer film:

①It has good mechanical properties, impact strength is 3~5 times that of other films, and good folding resistance.

②It is resistant to oil, fat, dilute acid, dilute alkali, and most solvents.

③It has excellent resistance to high and low temperatures. It can be used for a long time within a temperature range of 120°C, and can withstand high temperatures of 150°C and low temperatures of -70°C in short-term use, and has little effect on its mechanical properties at high and low temperatures.

④ The permeability of gas and water vapor is low, that is, it has excellent gas, water, oil and odor resistance.

⑤High transparency, can block ultraviolet rays and good gloss.

⑥Non-toxic, tasteless, good hygiene and safety, and can be directly used for food packaging. Because pet film has good stability, uniform tension, and minimal deviation of film thickness, it is most widely used.

Transfer flow

Feature

1.Environmental protection printing,meet the requierment of international non-toxic standard.

2.Four color process printing design finish in one time,no need for the color register.

3.Simple transfer equipment with vivid printing effect.

4.Strong covering power and good adhesive.

5.High gloss,high image definition,toxic free In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of heat transfer printing film for plastic,pe plastic film, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Specification

Production Process

- 1: Design

- 2: Making plate/cylinder<about need spend 7 days>

- 3: Prepare raw material

- 4: Prining<about 3 days>

- 5: Drying<3-5 working day>

- 6: Cutting<3-5 working days>

- 7: Cutting small sample and ship to customer test cutting size

- 8: QC

- 9: Packaging

- 10: Delivery

Packing and Shipping

Our company profile

Application Field

Application of pet heat transfer film Heat transfer film is suitable for hot stamping on the flat, curved, irregular,cylindrical, and conical surfaces of plastic, metal, leather, ceramics, wood and other products. It is widely used in daily necessities, cosmetics, stationery, toys, building materials, decorative materials, The surface printing and decoration of products in the industries of premium gifts, food packaging, signs, etc. and packaging. Such as the common plastic water cups in our lives, the beautiful heat transfer patterns on them are transferred on the heat transfer film of the water cup.

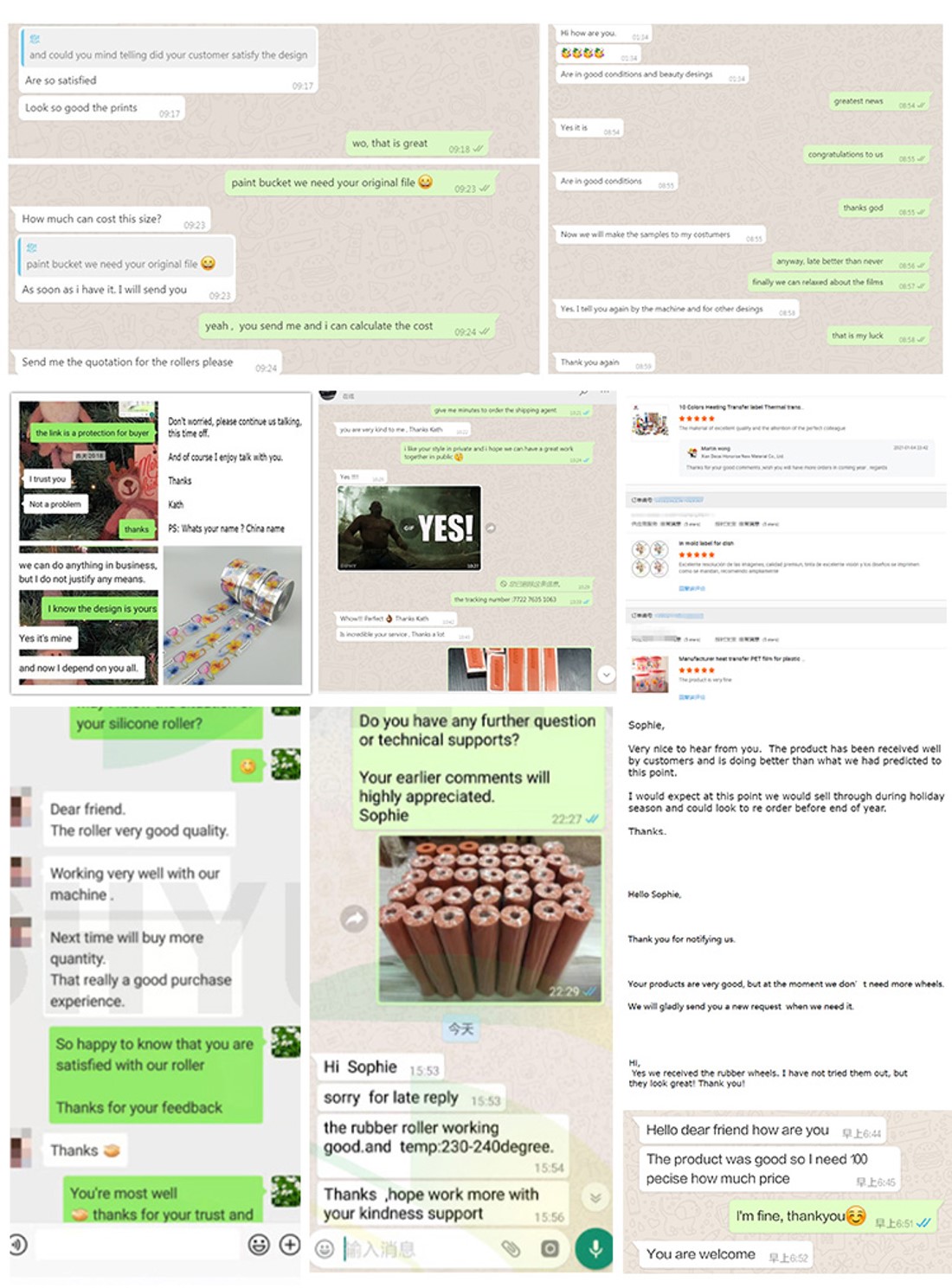

Feedback

FAQ

Q: What is "IML" ?

The term "in mold labeling" is directly derived from the technique: a preprinted polypropylene (PP) label is placed in a mold. Then the molten PP is added to the mold. It fuses with the label, and while curing, takes the shape of the mold. Effect: label and injection product become one.

Q: What makes IML unique?

1): Eco friendly 2): Strong and hygienic 3): Maximum print quality 4): Shorter production time 5): Quick design changeovers 6): Wide range of look and feel options

Contact Us

WhatsApp

0086-17779025926

Wechat:

0086-17779025926

labelprint02_vip@126.com