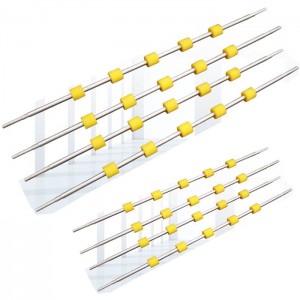

vulcanized polyurethane rubber wheels rubber roller price

The custom-made polyurethane rubber wheels roller has sufficient surface viscosity to ensure that the rubber roller has good ink transfer and inking performance during the printing process, and its good ink affinity can ensure high-quality printing.

What are the uses of bearing rubber wheels?

1. The function of bearing rubber-coated wheel can be adjusted in a large scale. Multiple physical and mechanical function targets can be changed within a certain scale through the selection of original materials and the adjustment of formulas, and then meet the different needs of users for product functions.

Rubber wheel

2. The bearing rubber-coated wheel has superior wear resistance. Especially in the presence of water, oil and other damp media, its wear resistance is usually dozens of times that of general rubber materials. It is worth noting that the friction coefficient of medium and low hardness polyurethane elastomer parts should be improved. To improve the wear resistance under load, a few lubricants such as aluminum disulfide and graphite can be added to this type of polyurethane elastomer.

3. There are various processing methods for bearing rubber-coated wheels and wide applicability. Polyurethane rollers can not only be molded with plastic refining and vulcanization technologies as general rubber; at the same time, they can also be made into pellets, which are the same as general plastics, and can be molded with technologies such as extrusion, calendering, and blow molding.

4. Bearing rubber wheels are resistant to ozone, radiation, low temperature, good sound permeability, excellent biocompatibility and blood compatibility.