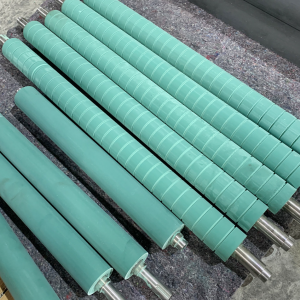

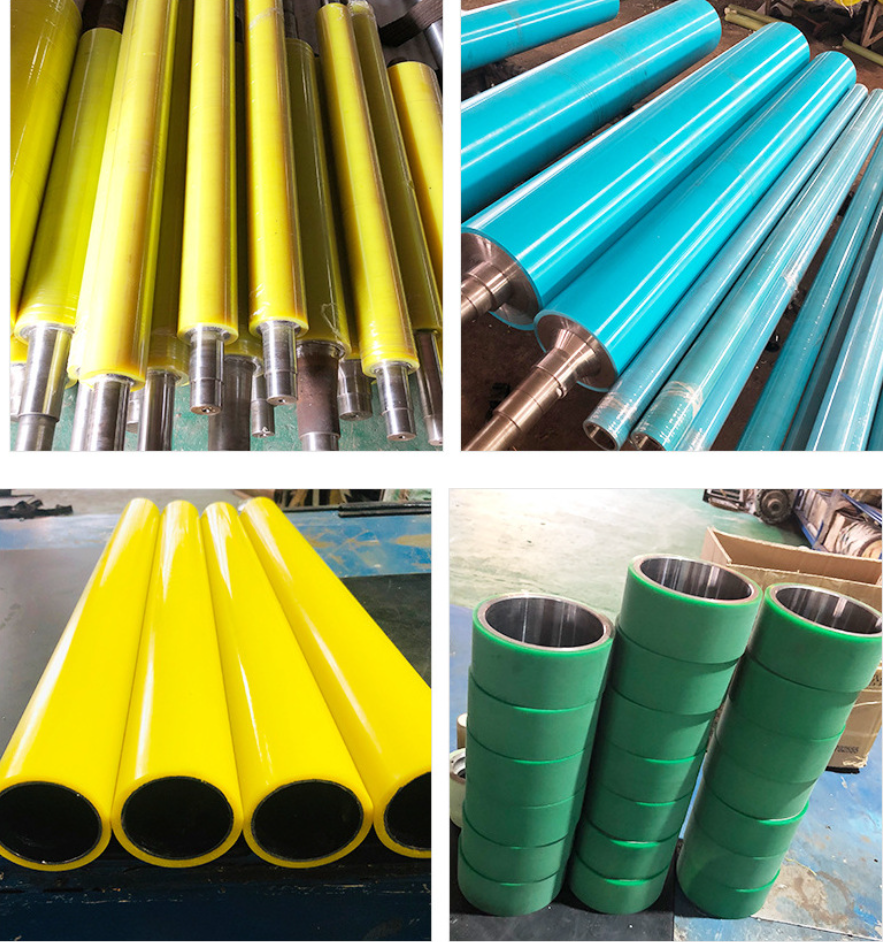

vulcanized printing rubber roller neoprene roller

Damage prevention and control measures of printing rubber roller neoprene roller :

1, rubber roller selection of wear-resistant and heat-resistant crack raw materials, the adoption of the corresponding thermal treatment and logistics chemical treatment methods, so that the arrangement is uniform, wear resistance appearance added.

2, rubber roller in the rolling mill before hardness, ultrasonic induction inspection, to ensure that it has no cracks and other shortcomings.

3, strengthen the equipment spot inspection, prevent rolling equipment incidents, reduce the occurrence of steel jam, pile of steel, rear-end and other incidents. Strictly control rolling temperature, eliminate low temperature steel through the mill, prevent rolling force overload.

4. Reasonable arrangement of roll change period, selection of rubber roller, formulation of specific rubber roller car repair plan, and control the car repair amount within the scale of demand.

5, reasonable placement of cooling water eruption scale and control of cooling water, ensure that the rubber roller cooling temperature control within the normal scale.

6. When rubber roller manufacturers turn, the residual oxide layer and cracks will be completely removed to reduce the appearance cracks and falling off of rubber rollers.

|

Decai Rubber Roller Specification

|

|

|

Size

|

Dia:10MM-670MM;

Length:50MM-8200MM

According To Customer's Drawing

|

|

Material

|

NBR,Silicone,Rubber,Polyurethane,NR,PU FFPM,ETC,EPDM

|

|

Hardness

|

18A-100D

|

|

Tolerance

|

0.05mm

|

|

Color

|

yellow,Black, orange,green or custome required

|

|

Core Material

|

stainless steel,45#steel or aluminum

|

|

Application Machine

|

industrial machine, printing machine and packaging machines and so on

|

|

Features of rubber roller |

1.Ozone and Chemical resistance

|

|

2.Anti-aging, good flexibility, good elasticity

|

|

|

3.Excellent oil resistance

|

|

|

4.Clean and healthy for many food and medical applications

|

|

The correct way to store the rubber roller is to wash it clean with clean water, and then seal it with plastic film, try not to let it contact with air, and then put it in a special place for storage, must not be swayed, affecting the internal mechanical properties and the quality of the rubber surface. The internal bearing and shaft head need good lubrication rubber roller manufacturers suggest that, in daily circumstances, every week to use the rubber roller to make relevant maintenance, the rubber surface and internal lubrication to do good enough.