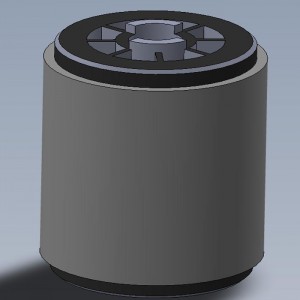

Wear resistant pu rubber rollers with Nylon core

The core of the rubber roller is plastic nylon injection forming, and then coated PU polyurethane rubber rubber on Nylon core.

DECAI produces all kinds of plastic core rubber wheels rollers, customized according to your drawings and requirements, the factory sales directly, welcome to contact

What is a polyurethane rubber wheel? Let's get to know polyurethane first! The raw materials of polyurethane materials are generally presented in a resin state. In addition to being a relatively single-component material, it can also be mixed with other materials to form composite materials.

There are many varieties of polyurethane, including hard, soft and polyurethane elastomers. It can also be divided into two categories: thermoplastic and thermosetting. It is now a kind of insulation material with good performance in the world, because it has Good oil resistance, toughness, abrasion resistance, aging resistance and adhesion, so it has a wide range of uses.

Construction industry, transportation industry, chemical industry, including home, will have polyurethane materials. For example, in terms of furniture, it can play a role in sofas, mattresses and armrests of seats. The advantages of using polyurethane encapsulation on mechanical parts are also many. Firstly, the hardness is improved, and then the strength is also improved. Compared with rubber, their tearing strength, tearing strength and load-bearing capacity are better than ordinary ones. The rubber is much higher.

Polyurethane is an elastomer which is a kind of strong polar polymer compound. It has little affinity with non-polar mineral oil, and it is hardly corroded in fuel oil and machine oil. Soothing aging, superior performance, good oxygen and ozone resistance is really a good material.