Wholesale pet material heat transfer film for plastic cup bottle jar print

Product description

Heat transfer film for printing on plastic cups and cans is a specialized material used to apply durable, high-quality designs onto surfaces. It typically consists of a polyester carrier film coated with layers of ink, adhesive, and sometimes a protective topcoat. The design is printed in reverse on the film, which is then placed onto the plastic surface. Through heat and pressure, the ink and adhesive layers transfer onto the plastic, bonding securely. This method ensures vibrant, long-lasting prints resistant to fading, scratching, and washing. Heat transfer films are ideal for customizing drinkware, offering versatility in design and compatibility with various plastic materials, making them popular in promotional and retail industries.

Product show

1) Your product color is too dark,and the white base of the thermal transfer film is not thick, resulting in the product colorshowing through after printing. You can use 2 or even 3 layers of white on the design artwork.

2)Thicken and deepen the white ink,or use high-concentration white.

Q:How to ensure that the colors of design drawings are more standard?

1) For the electronic draft, the customer confirms the color and size. If there is a 5% difference between the product and the design draft, the customer will be informed in advance.

2) Use Pantone color cards to compare color numbers with customers.

Production process

The production of heat transfer film involves several key steps:

Make cylinder:The process begins with creating a printing cylinder. The desired design is engraved onto the cylinder, which will be used to transfer the ink onto the film.

Printing:The engraved cylinder is then used in the printing process. Ink is applied to the cylinder, which transfers the design onto the polyester carrier film. Multiple layers of ink may be applied to achieve the desired colors and effects.

Dry:After printing, the film passes through a drying oven to cure the ink. This ensures that the ink adheres properly to the film and prevents smudging or bleeding.

Cutting:Once the film is dry, it is cut into the required sizes and shapes. This step ensures that the film is ready for application onto the final product, such as plastic cups or cans.

Quality Inspection:The cut film undergoes a thorough quality inspection. This step checks for any defects, such as misprints, color inconsistencies, or imperfections in the film. Only films that meet the quality standards proceed to the next step.

Packaging and Shipping:The final step involves packaging the heat transfer film securely to protect it during transportation. The packaged film is then shipped to customers or distributors, ready for use in various applications.

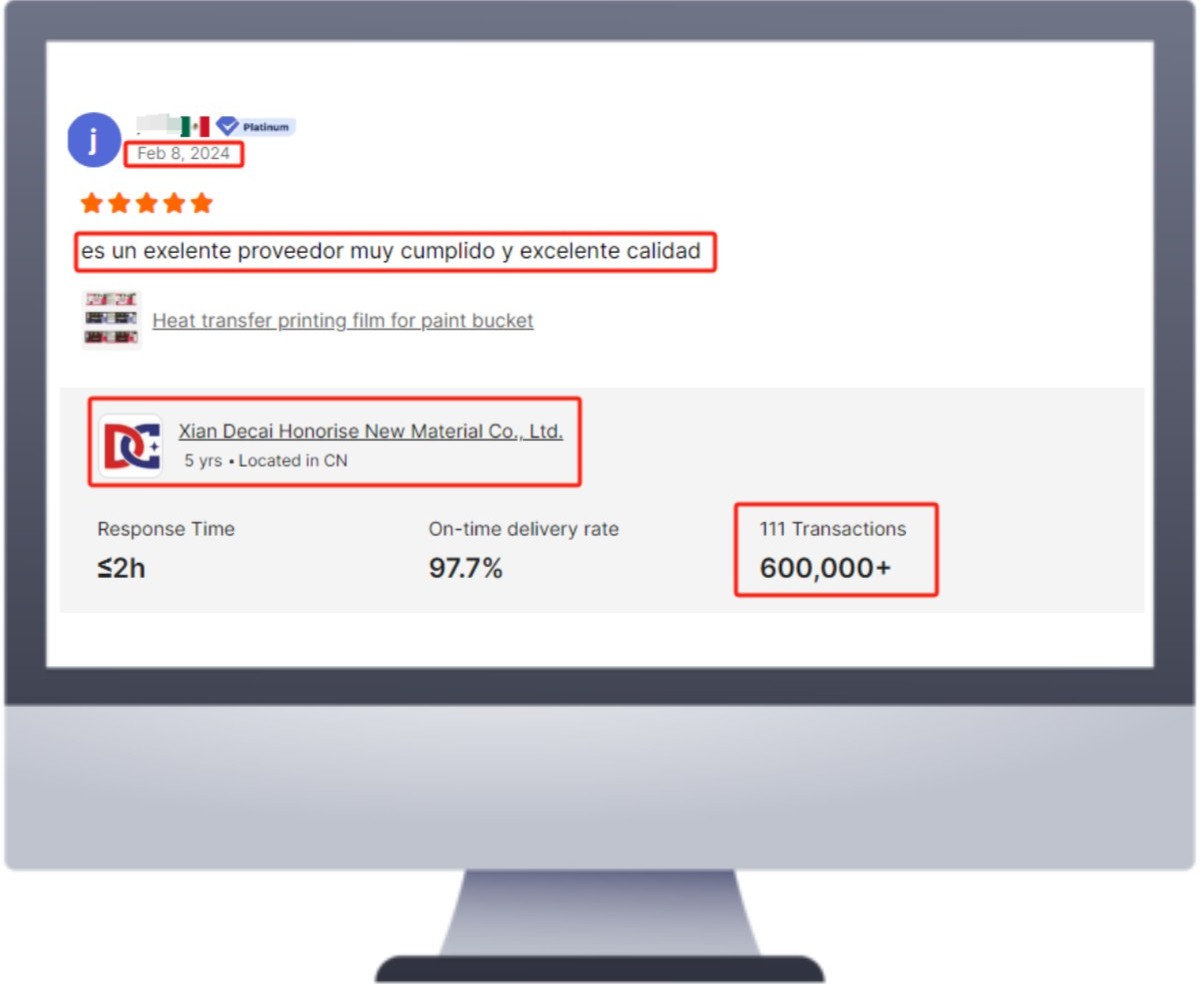

Company profile

Decai Honorise is a leading manufacturer of heating transfer field, one-stop service comprehensive enterprise. The products involves the following major aspects:High-precision hot stamping silicone rubber roller and wheel、gravure printing rubber roller and various industrial rubber rollers,Thermal transfer film labels and in-mold labeling,Heat transfer machine and hot stamping machine.Integrating production, sales and R&D together. In strict accordance with printing industry standards for production and management. We're own scientific formula, precise processing methods and superb grinding technology, we provide high-quality products with advanced production equipment and strong technical force.

Exhibition&Feedback

Packing&Shipping

FAQ

1.Are you a manufacturer?

2.Can you provide samples?

Yes, we can provide you samples for quality checking. Please let us know your requirements, then we can arrange samples according to your requirements. Our samples are free, but the delivery charge is on your side.

3.How can we guarantee quality?

Always a pre-production sample before mass production;Always final Inspection before shipment.

4.What is "heat transfer printing' ?

Heat transfer film uses PET raw materials and prints customized artwork on the PET raw materials through gravure printing technology. After the customer receives the heat transfer film, the pattern on the PET raw material is transferred to the surface of the product using the high-temperature printing of the heat transfer machine, thus forming a decorative effect.

5.How to use heat transfer printing ?

1)firstly you must have a heat transfer printing machine, we also produce this machine

3) your product should have smooth surface(flat or round conical shape)

6.This is the first time to buy, what information I need to provide in order to get a price?

1)Material of your product

2)Size of the film /your product

3)do you have own orginal design?

4) Order quantity

5)If possiable pls send sample product to us

7.How can we contact you as soon as possible?

We are always available on Alibaba.com, WhatsApp, Wechat. You can also reach us by email. You are welcome to send us any questions anytime and we will reply you.

Related products

Heat transfer machine

Metallic heat transfer film